- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

insulated iron wire

The Magic of Insulated Iron Wire Applications and Benefits

Insulated iron wire is a versatile and essential material in various fields, including construction, manufacturing, and electrical engineering. As one of the most durable and cost-effective conductive materials available, insulated iron wire provides numerous advantages in terms of safety, efficiency, and longevity. This article will explore the structure, properties, applications, and benefits of insulated iron wire, highlighting why it remains a staple in multiple industries.

Structure and Composition

Insulated iron wire consists of iron strands or conductors that are covered with a non-conductive insulation layer. The insulation is typically made from materials such as PVC (polyvinyl chloride), PE (polyethylene), or rubber, which offer excellent resistance to moisture, chemicals, and abrasion. This layer not only protects the iron wire from environmental factors that could cause corrosion and deterioration but also prevents electrical leakage, ensuring safety in electrical applications.

Moreover, the choice of insulation material can influence the wire's thermal properties and flexibility, allowing it to be tailored for specific uses. The gauge and composition of the iron wire itself can also vary, accommodating different load requirements and electrical capacities.

Applications in Electrical Systems

One of the primary applications of insulated iron wire is in electrical systems, where it acts as a conductor for transmitting electrical power. The insulation prevents accidental contact with live wire surfaces, thereby minimizing the risk of short circuits or electrical shocks. Insulated iron wire is commonly used in residential and commercial wiring, light fixtures, and electrical appliances.

Notably, insulated iron wires are favored for their strength and low resistance to electrical flow. They can handle a considerable amount of electrical current, making them ideal for high-power applications such as industrial machinery, construction sites, and energy distribution systems. Additionally, insulated iron wire is often used in telecommunications, where it connects various components within a network while maintaining signal integrity.

Construction and Infrastructure

insulated iron wire

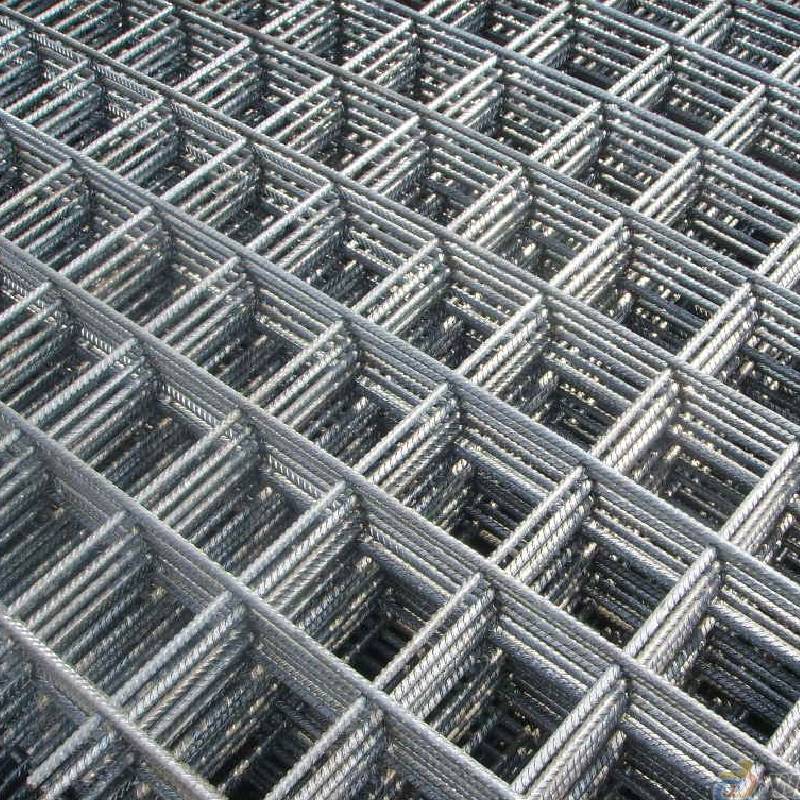

Beyond electrical applications, insulated iron wire plays a crucial role in construction and infrastructure projects. It is used extensively in the reinforcement of concrete structures, providing added strength and flexibility. For instance, insulated iron wire is commonly utilized in making reinforced concrete slabs, beams, and columns, where it helps to distribute loads evenly and prevent cracking.

Additionally, the wire can be employed in fencing, straining cables, and anchoring systems for buildings and retaining walls. The insulating layer ensures that the wire remains functional and corrosion-resistant, extending its lifespan and durability in harsh environmental conditions.

Advantages of Insulated Iron Wire

The benefits of using insulated iron wire are manifold. Primarily, the insulation provides a layer of safety for both the equipment and individuals working with or around the wire. This feature significantly reduces the risk of accidents, making it a preferred choice in both industrial and residential settings.

Moreover, the durability of the insulation allows the wire to withstand adverse weather conditions, chemical exposure, and physical wear and tear. This resilience means that insulated iron wire requires less frequent replacement, leading to reduced maintenance costs and less waste.

In terms of conductivity, insulated iron wire has a lower resistance than many alternatives, ensuring efficient energy transfer. This quality is particularly beneficial for energy-intensive applications where minimizing energy loss is crucial to economic and environmental sustainability.

Conclusion

Insulated iron wire is an invaluable component across various sectors, from electrical engineering to construction, thanks to its versatility, durability, and safety features. Its ability to conduct electricity efficiently while providing a protective insulating layer ensures that it remains a preferred choice in many applications. As technology continues to evolve, the demand for reliable conductive materials like insulated iron wire will likely persist. Its capabilities and benefits will continue to support innovation and development in both existing and emerging fields, solidifying its place as a key material in our modern world. Whether in the infrastructure that supports our daily lives or the electrical systems that power our devices, insulated iron wire truly exemplifies the blend of functionality and safety in engineering materials.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025