- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

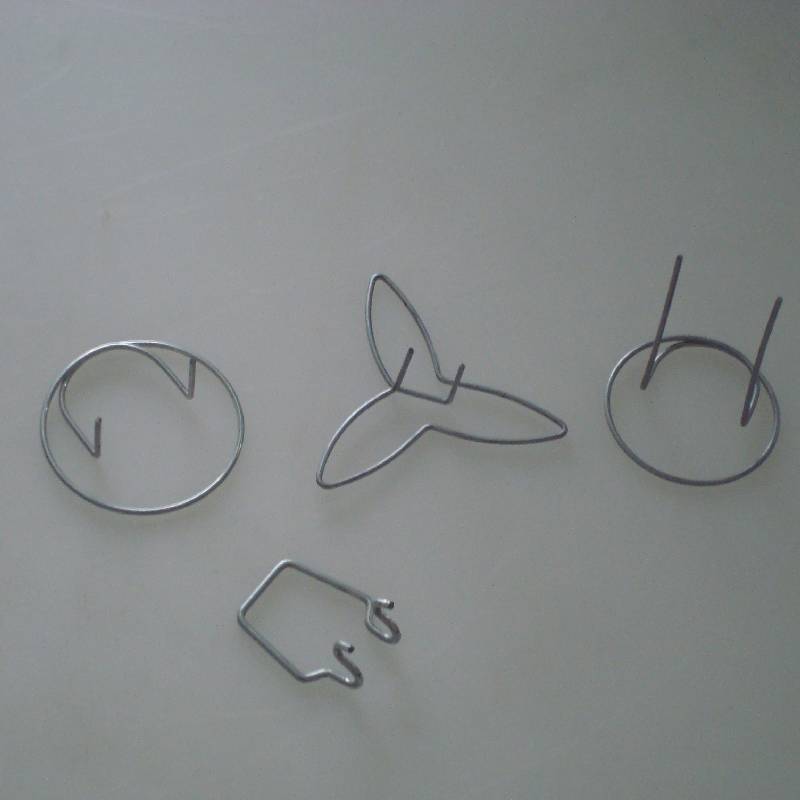

industrial extension springs

Understanding Industrial Extension Springs Key Features and Applications

Industrial extension springs are essential components widely used in various mechanical applications. They are designed to absorb and store energy, providing resistance when they are stretched. As a type of coil spring, extension springs work under tension and are engineered to return to their original form after being elongated. This article explores the significance, characteristics, and applications of industrial extension springs.

What are Extension Springs?

Extension springs are helical springs that are designed to operate in tension. They are manufactured from various materials, including stainless steel, music wire, and other alloys, ensuring durability and resistance to wear and tear. The main function of an extension spring is to resist any pulling force applied to it, making them instrumental in a variety of mechanisms.

The design of extension springs includes tightly coiled coils that allow for maximum energy storage. The ends of these springs can either be hooked or looped, facilitating easy attachment to other components. The degree of tension is determined by the number of coils and the diameter of the wire used during fabrication. Furthermore, the spring rate is a critical aspect that determines how much force is required to stretch the spring a certain distance.

Key Features of Industrial Extension Springs

1. Material Versatility Extension springs can be made from various materials, including carbon steel, stainless steel, and other specialty alloys, giving manufacturers options based on the specific application requirements. Stainless steel extensions, for example, offer excellent corrosion resistance, making them ideal for outdoor or harsh environments.

2. Tailored Design Extension springs can be customized to fit specific needs. Manufacturers can produce springs in a wide range of sizes, coil diameters, and free lengths. This customization allows for optimal performance in different applications, ensuring that the spring will function correctly under the intended load.

3. Tension Characteristics The tension characteristics of the spring are crucial in determining its applications. Extension springs are specifically designed to provide a high level of force and return to their original state quickly upon the removal of the load. This characteristic is vital for applications where responsiveness is key.

4. Force Displacement Characteristics The force exerted by an extension spring is directly proportional to how far it is stretched from its resting position. This linear behavior makes it easy to predict performance and integrate into various mechanical systems.

industrial extension springs

Applications of Extension Springs

Extension springs are utilized in numerous industries and applications

. Here are some typical uses1. Automotive In the automotive sector, extension springs are commonly used in hoods, trunk lids, and various suspension systems. They help in providing the necessary tension for smooth operation.

2. Aerospace The aerospace industry employs extension springs in various aircraft components, such as flaps and landing gear systems, where reliable performance is critical to safety.

3. Manufacturing In manufacturing machinery, extension springs are essential in conveyor belts and automated systems, where they help maintain tension and functionality.

4. Consumer Products Many household items, such as clothespins, toys, and retractable leashes, use extension springs for their functionality, demonstrating their versatility in everyday applications.

5. Medical Equipment In medical devices, extension springs are used in various equipment to provide necessary tension and functionality, reflecting their importance in critical environments.

Conclusion

Industrial extension springs are vital components that play a significant role in numerous applications. Their ability to operate under tension while providing controlled force output makes them indispensable in sectors ranging from automotive to healthcare. With diverse material options and customizable designs, extension springs can meet the specific needs of any application. As technology advances, the development of extension springs will continue to evolve, ensuring their relevance in an increasingly demanding industrial landscape. Understanding their features and applications allows engineers and designers to harness the full potential of these crucial components in their projects.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025