- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Guidelines for Installing Hy Rib Mesh Effectively and Safely

Installation of HY Rib Mesh A Comprehensive Guide

The use of rib mesh, particularly HY rib mesh, in construction and engineering projects has become an essential practice due to its numerous benefits. These benefits include increased structural integrity, improved crack resistance, and enhanced overall reliability. Ensuring proper installation of HY rib mesh is vital to fully leverage its advantages. This article will guide you through the installation process, detailing each step to ensure optimal results.

Understanding HY Rib Mesh

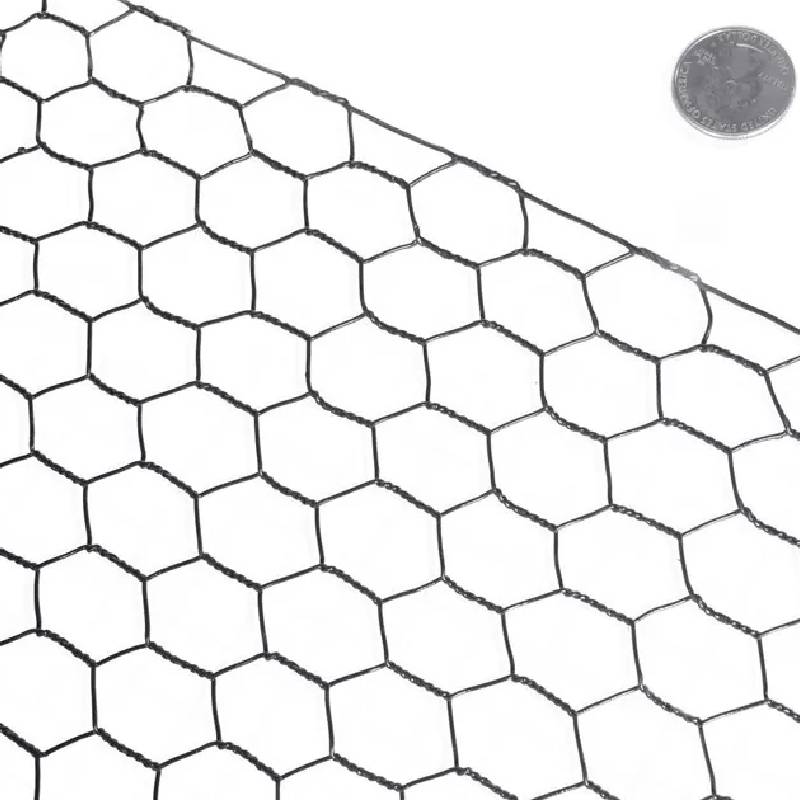

HY rib mesh is a type of welded wire mesh designed to reinforce concrete structures. Its distinct ribbed design makes it ideal for a variety of applications, from flooring systems to precast concrete elements. The ribs provide additional bonding surface between the mesh and concrete, enhancing load distribution and strength.

Preparing for Installation

Before commencing the installation, careful planning and preparation are crucial. Here are a few key steps

1. Site Assessment Evaluate the construction site to ensure it meets safety standards and there are no obstacles that could hinder the installation process.

2. Material Check Verify that the HY rib mesh is of the correct specification and quality. It should be free from any damages such as rust, bends, or malformed sections.

3. Required Tools Gather necessary tools including wire cutters, pliers, measuring tape, and a concrete mixer if needed. Ensuring you have all tools at hand will streamline the process.

Installation Process

hy rib mesh installation

1. Measuring and Cutting Start by measuring the area where the mesh will be installed. Cut the HY rib mesh to the appropriate size using wire cutters. Always leave some overlap at the edges to ensure proper bonding.

2. Positioning Place the cut mesh on the designated area, ensuring that it lies flat and is adequately supported. For larger areas, consider placing spacers to maintain an even elevation above the ground.

3. Securing the Mesh Using ties or clips, secure the rib mesh in place. This will prevent movement during the concrete pouring process. It's essential to ensure that the mesh is positioned within the recommended cover depth from the concrete surface to achieve optimal reinforcement.

4. Pouring Concrete Once the mesh is in position and secured, it's time to pour the concrete. Ensure a consistent pour to avoid gaps. Use a vibrating tool if necessary to remove air pockets and ensure even distribution of the concrete over the mesh.

5. Finishing After the concrete has been poured, finish the surface as required. This may involve smoothing out the top layer or applying treatments depending on the project specifications.

Quality Control and Inspection

Post-installation, it's vital to conduct quality checks. Inspect the installation to ensure that the mesh is not exposed on the surface and that the concrete has adhered properly. Evaluate the overall structural integrity to identify any potential issues early on.

Conclusion

The installation of HY rib mesh is a significant step in the construction process, contributing to the durability and longevity of concrete structures. By following the outlined steps and ensuring a meticulous approach, you can achieve high-quality results that will enhance the performance of your project. Proper installation not only maximizes the inherent benefits of the rib mesh but also provides peace of mind knowing that the structure is built to last. Thus, investing time in thorough preparation and execution pays off in the long run.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025