- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

High Capacity Tension Springs for Extreme Load Applications and Durability Solutions

Understanding High Load Extension Springs Applications, Benefits, and Selection

High load extension springs are specialized mechanical components designed to withstand significant tension loads while maintaining their shape and functionality. These springs play a critical role in various industries, including automotive, aerospace, manufacturing, and consumer products. This article delves into the applications, benefits, and factors to consider when selecting high load extension springs.

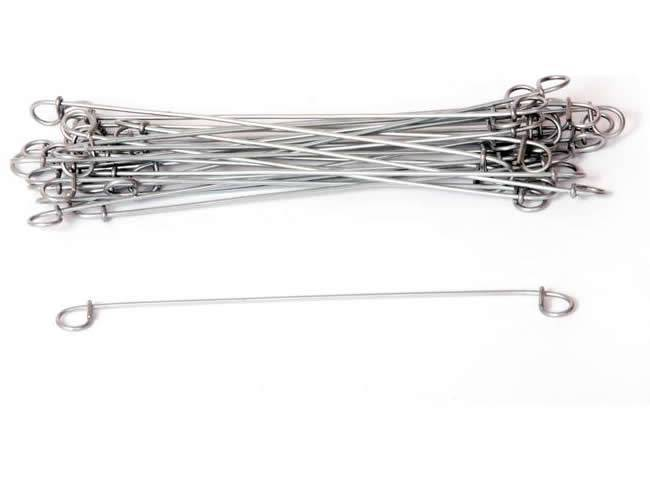

What Are High Load Extension Springs?

Extension springs are tightly coiled coils of wire that store energy when stretched. They are designed to absorb and release energy efficiently, making them ideal for applications requiring a return force. High load extension springs, as their name suggests, are capable of handling heavy loads without compromising their structural integrity. Typically made from high-strength materials such as stainless steel or music wire, these springs are engineered to meet the demands of rigorous environments.

Applications of High Load Extension Springs

High load extension springs are versatile components used in various applications. Some of the most common include

1. Automotive Industry In automotive design, these springs are used in suspensions, brake systems, and seat mechanisms, where they provide the necessary support and flexibility under stress.

2. Aerospace The aerospace sector relies on high load extension springs in landing gear systems, control systems, and various structural components, where they help manage loads while ensuring safety and performance.

3. Manufacturing In manufacturing equipment, these springs are utilized in conveyor systems, packaging machines, and assembly lines, assisting in the mechanical movement and operation of machinery.

4. Consumer Products Many household items, such as lawnmowers, sports equipment, and furniture, use high load extension springs to enhance functionality and durability.

Benefits of High Load Extension Springs

The use of high load extension springs offers several advantages that contribute to the overall efficiency and reliability of mechanical systems

high load extension springs

1. Durability Made from high-quality materials, these springs have increased fatigue resistance, allowing them to maintain their performance over extended periods, even under heavy loads.

2. Versatility High load extension springs can be customized in terms of size, diameter, and load capacity, making them suitable for a wide array of applications.

3. Cost-Effectiveness While the initial investment in high load extension springs may be higher than conventional springs, their longevity and reliability often lead to reduced maintenance and replacement costs.

4. Energy Efficiency These springs are designed to store and release energy efficiently, which can improve the overall energy efficiency of mechanical systems.

Selecting High Load Extension Springs

When selecting high load extension springs for a specific application, several factors must be considered

1. Load Requirements Determine the maximum load that the spring needs to handle. This will guide the selection process in terms of wire diameter and coil dimensions.

2. Environmental Conditions Consider the working environment, including temperature, humidity, and exposure to chemicals, which may affect the choice of material.

3. Dimensions and Space Restrictions Assess the space available for the spring installation to ensure that the selected spring fits the design constraints.

4. End Fittings Various end fittings, such as hooks or loops, may be required depending on the application. Ensure that these are compatible with the overall design.

5. Coil Configuration Depending on the energy storage needs, choose between different coil configurations that can provide the desired performance.

In conclusion, high load extension springs are essential components in many mechanical systems, providing strength, durability, and versatility. By understanding their applications, advantages, and the critical factors for selection, engineers and designers can effectively incorporate these springs into their projects, ensuring optimal performance and reliability.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025