- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

High-Quality PVC Coated GI Wire for Durable and Reliable Construction Applications

The Versatility of PVC Coated GI Wires

In the realm of construction, agriculture, and fencing, materials play a crucial role in defining the quality and durability of a project. One such material that has gained popularity over the years is PVC coated Galvanized Iron (GI) wire. The charm of PVC coated GI wire lies not only in its functionality but also in its versatility, making it ideal for various applications across different industries.

Understanding PVC Coated GI Wire

The core of PVC coated GI wire is galvanized iron wire, which undergoes a process of galvanization to prevent corrosion. Galvanization involves coating the iron wire with a layer of zinc, a technique that significantly enhances the wire’s resistance to rust and environmental factors. Once this protective layer is applied, a layer of Polyvinyl Chloride (PVC) is added, creating a strong, durable, and weather-resistant product. The combination of these two materials results in a wire that maintains flexibility while providing exceptional strength and resistance to wear and tear.

Benefits of PVC Coated GI Wire

1. Corrosion Resistance Perhaps the most significant advantage of using PVC coated GI wire is its ability to withstand harsh weather conditions. The galvanized layer protects against oxidation, while the PVC coating adds an extra layer of protection, making it suitable for both indoor and outdoor applications.

2. Aesthetic Appeal PVC coatings come in various colors, offering an added advantage when aesthetic considerations are necessary. Whether for residential fencing or decorative purposes, these wires can easily blend with the surroundings, enhancing the overall look of a property.

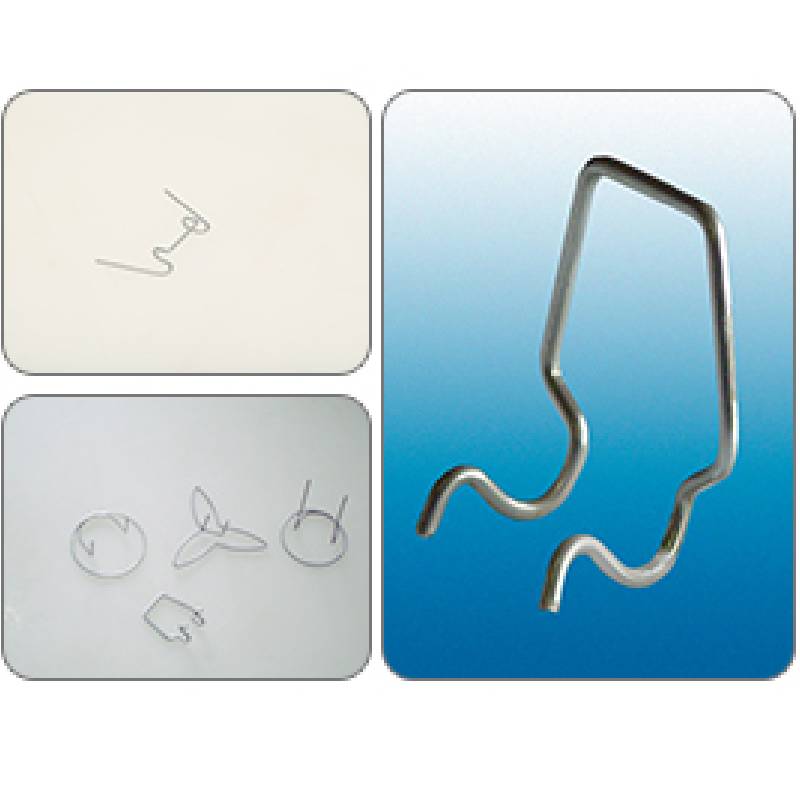

pvc gi wire

3. Durability vs. Flexibility While it is strong, PVC coated GI wire is also quite flexible. This characteristic makes it easier to handle and install, perfect for projects that require intricate designs or secure fencing around uneven terrain.

4. Low Maintenance The combination of galvanized iron and PVC means that once installed, these wires require minimal maintenance. The protective layers limit rust and corrosion, meaning property owners can enjoy peace of mind without frequent repairs.

Applications of PVC Coated GI Wire

The uses of PVC coated GI wire are vast and varied. Common applications include fencing for homes, gardens, and farms, where it is essential to keep animals secure and property delineated. Additionally, it is widely employed in construction projects such as reinforcing concrete or creating partitions.

In agriculture, the wires are utilized for trellising plants or creating protective barriers against pests, proving to be an efficient fencing solution for orchards and vineyards. Moreover, due to its strength and durability, PVC coated GI wire is also used in the manufacturing of wire mesh and nets for various applications, from safety nets to storage solutions.

Conclusion

In conclusion, PVC coated GI wire epitomizes the perfect balance between strength and aesthetics. Its resilience against rust and corrosion, combined with its versatility and low maintenance needs, make it a prime choice for industries ranging from construction to agriculture. As the demand for sustainable and durable building materials rises, PVC coated GI wire represents a smart investment for anyone looking to enhance the quality and longevity of their projects. Whether you are a homeowner, contractor, or farmer, incorporating PVC coated GI wire into your plans can lead to more robust and visually appealing results, ensuring both functionality and style.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025