- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Durable Welded Wire Mesh for Various Industrial Applications and Strength Needs

Understanding Heavy Welded Wire Mesh Applications and Benefits

Heavy welded wire mesh is a versatile and robust material widely utilized in various industrial and construction applications. Comprising thick wires that are welded together at their intersections, this type of wire mesh is renowned for its strength, durability, and structural integrity. The manufacturing process typically involves high-quality steel wires that are welded to create a grid pattern, ensuring that the mesh can withstand significant loads and harsh conditions. This article explores the various applications, benefits, and factors to consider when choosing heavy welded wire mesh.

Applications of Heavy Welded Wire Mesh

Heavy welded wire mesh is utilized in an array of applications across different industries. One of the most common uses is in the construction sector, where it serves as reinforcement for concrete structures. By adding this mesh to concrete mixtures, it enhances the overall strength and reduces the risk of cracking. Additionally, heavy welded wire mesh is often employed in the creation of industrial flooring and screens, providing a solid foundation for machinery and equipment.

Another significant application is in the agricultural sector, where it is used for livestock enclosures, fencing, and protection of crops. The durability of heavy welded wire mesh ensures that it can withstand environmental factors while keeping livestock safe and secure. Furthermore, this type of wire mesh can be found in architectural applications, such as in the construction of decorative features and safety barriers.

Benefits of Heavy Welded Wire Mesh

One of the primary benefits of heavy welded wire mesh is its unparalleled strength. The welding process creates a rigid and sturdy product that can bear heavy loads, making it ideal for industrial applications where reliability is critical. Additionally, the thickness of the wires used in heavy welded wire mesh contributes to its robustness, allowing it to resist damage from impact and environmental wear.

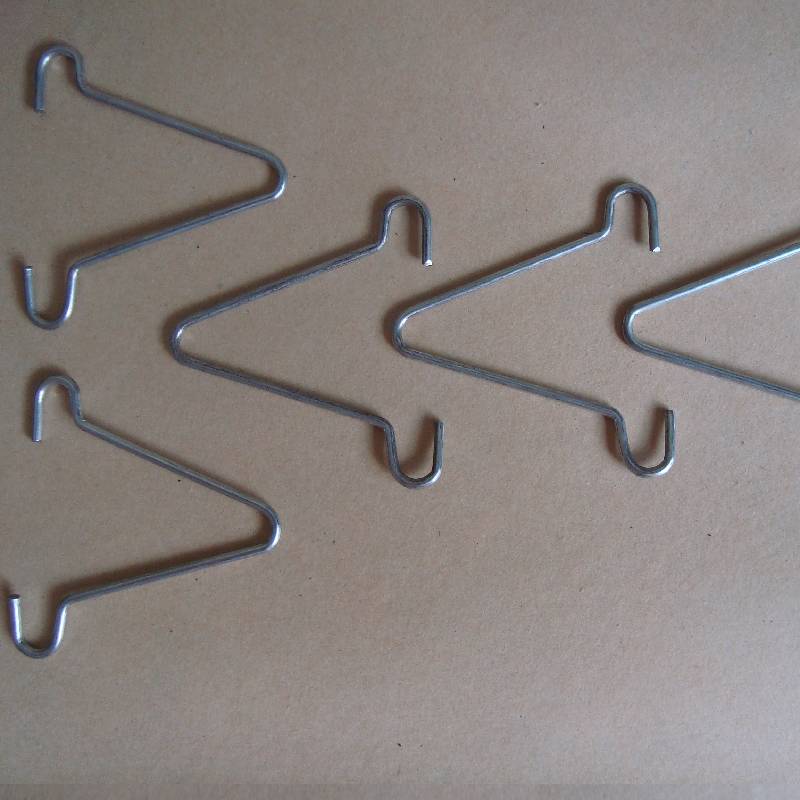

heavy welded wire mesh

Another advantage is its versatility. Heavy welded wire mesh can be customized to suit various sizes, shapes, and applications, making it suitable for a wide range of projects. Whether for construction, agriculture, or safety barriers, this mesh can be tailored to meet specific requirements.

Moreover, heavy welded wire mesh is low maintenance. Due to its construction with high-quality steel, it often comes with coatings that provide corrosion resistance, ensuring that the mesh retains its integrity even in adverse weather conditions. This characteristic translates to longer lifespans, reducing the need for frequent replacements or repairs.

Selecting the Right Heavy Welded Wire Mesh

When choosing heavy welded wire mesh, several factors should be considered. First, the intended application will influence the specifications you require. For example, the gauge of the wire and the spacing between welds can vary depending on the load and environment.

Additionally, it’s important to assess the environment where the mesh will be installed. If it will be exposed to moisture or corrosive substances, opting for a galvanized version may provide additional protection.

Finally, working with a reputable supplier is crucial. Ensure that the supplier can provide detailed specifications and quality assurance for their products, which will guarantee that you are making an informed investment.

In conclusion, heavy welded wire mesh is a material that offers significant strength, durability, and flexibility across numerous applications. Understanding its benefits and choosing the right specifications is essential for maximizing its effectiveness in your projects. Whether you're in construction, agriculture, or any other industry, heavy welded wire mesh is a reliable choice that can enhance the safety and longevity of your structures and systems.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025