- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Durable Stainless Steel Mesh for Heavy-Duty Applications and Industrial Use

The Versatility and Strength of Heavy-Duty Stainless Steel Mesh

In today's world, where durability and strength are paramount in various applications, heavy-duty stainless steel mesh stands out as an ideal material. This specialized mesh combines resilience, flexibility, and corrosion resistance, making it suitable for a wide range of industries, from construction to manufacturing and agriculture.

What is Heavy-Duty Stainless Steel Mesh?

Heavy-duty stainless steel mesh is a type of woven material made from high-grade stainless steel wires. The “heavy-duty” designation indicates that it has been designed to withstand significant stress and strain, making it ideal for heavy applications. The mesh typically features a fine or coarse weave that can be tailored to meet specific requirements for size and strength. The most common grades used in the production of this mesh include 304 and 316 stainless steel, each offering unique properties suited to different environments.

Benefits of Using Heavy-Duty Stainless Steel Mesh

1. Corrosion Resistance One of the standout features of stainless steel is its ability to resist rust and corrosion. This makes heavy-duty stainless steel mesh an excellent choice for outdoor applications, marine environments, and in industries where exposure to harsh chemicals is common.

2. Strength and Durability The high tensile strength of stainless steel allows this mesh to handle heavy loads without compromising its structural integrity. This characteristic makes it ideal for reinforcing structures, supporting heavy equipment, or serving as protective barriers.

3. Versatility Heavy-duty stainless steel mesh can be used in a multitude of applications. It is commonly utilized in construction for safety barriers, in food processing for conveyor belts, and in agriculture for fencing and animal enclosures. Its adaptability makes it a preferred choice across different sectors.

4. Easy Maintenance Unlike other materials that may require extensive upkeep, stainless steel mesh is relatively easy to clean. A simple wash with water and mild detergent is often sufficient to maintain its appearance and functionality.

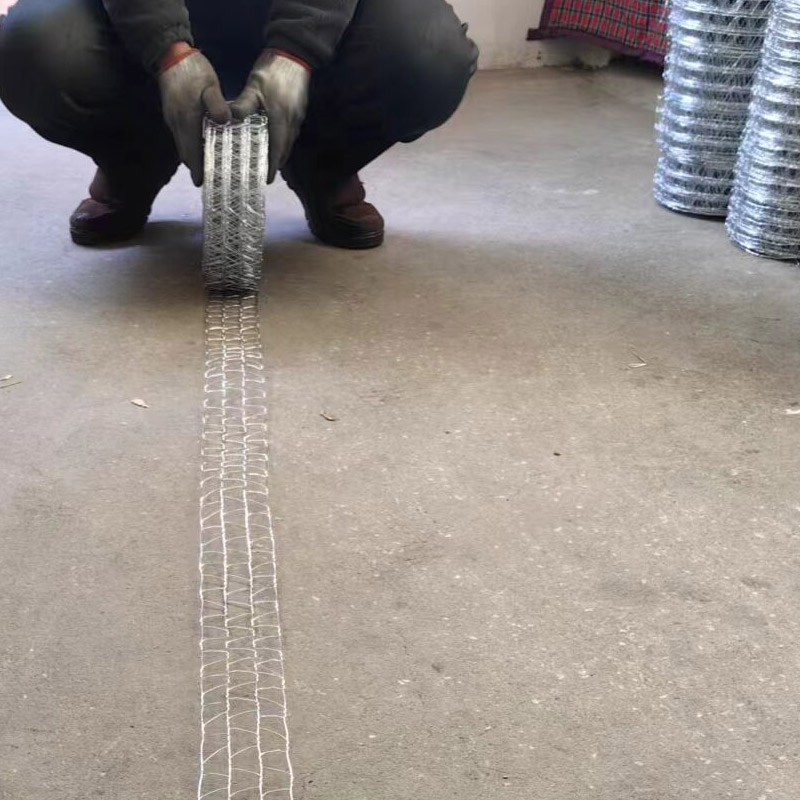

heavy duty stainless steel mesh

5. Aesthetic Appeal With a sleek, metallic finish, heavy-duty stainless steel mesh can enhance the aesthetic appeal of various designs. It is commonly used in architectural applications, including railings and decorative screens, where both function and form are essential.

Applications of Heavy-Duty Stainless Steel Mesh

Industrial Uses In the manufacturing sector, stainless steel mesh is widely used for filtration, sieves, and conveyor belts. Its ability to handle high volumes and resist wear makes it invaluable in these applications.

Construction In construction, heavy-duty stainless steel mesh serves as reinforcement in concrete structures. It is also used for scaffolding and as safety barriers to protect workers and pedestrians.

Agriculture Farmers utilize stainless steel mesh for fencing, storage bins, and animal enclosures. Its strength and durability ensure that it withstands the rigors of outdoor environments.

Food Processing The food industry requires materials that meet strict health and safety standards. Heavy-duty stainless steel mesh is non-reactive, making it ideal for use in food processing and preparation areas.

Marine Applications In marine environments, corrosion resistance is critical. Stainless steel mesh is used in shipbuilding and as protective nets to ensure safety without compromising performance.

Conclusion

Heavy-duty stainless steel mesh is a remarkable material that combines strength, durability, versatility, and aesthetic appeal. Its long-lasting properties and ease of maintenance make it a smart investment for various industries. As technology and applications evolve, the demand for stainless steel mesh will likely continue to grow, cementing its place as a cornerstone material in construction, manufacturing, agriculture, and beyond. Whether for a practical application or a decorative enhancement, heavy-duty stainless steel mesh proves its worth time and again, offering unmatched performance and reliability.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025