- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

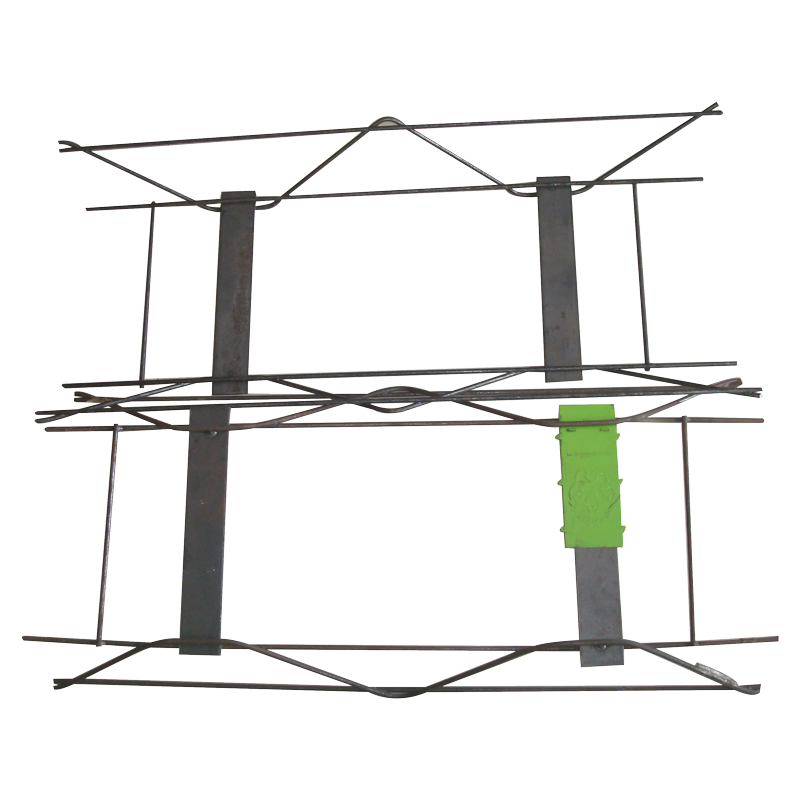

heavy duty extension springs suppliers

Heavy Duty Extension Springs Suppliers and Considerations

Extension springs are essential components utilized in a vast array of applications across various industries. Engineered to store and release energy, these springs are primarily designed to work under tension, making them crucial for mechanisms ranging from garage doors and automotive parts to exercise equipment and industrial machinery. When it comes to sourcing heavy-duty extension springs, the choice of supplier can significantly impact the quality, durability, and performance of the springs, making it imperative to choose wisely.

Understanding Heavy Duty Extension Springs

Heavy-duty extension springs are characterized by their ability to withstand significant loads and stresses. They are fabricated from high-quality materials such as stainless steel or high-carbon steel, providing enhanced resistance to wear, fatigue, and corrosion. These springs come in various shapes, sizes, and specifications to cater to specific applications, ensuring that the right spring is available for a given requirement. The performance of heavy-duty extension springs is often determined by factors such as wire diameter, coil diameter, overall length, and the number of coils, making it crucial for suppliers to provide detailed specifications.

Importance of Reliable Suppliers

When looking for heavy-duty extension spring suppliers, several factors come into play. Reliability is a top criterion; a reputable supplier can ensure consistent quality and timely delivery. Furthermore, suppliers with an established reputation are typically more knowledgeable about industry standards and can provide valuable guidance on the right spring selection for particular applications.

Another aspect to consider is the supplier's range of products. A supplier that offers a comprehensive inventory of heavy-duty extension springs can cater to diverse needs, which is especially beneficial for clients who require customized solutions. This flexibility often leads to reduced lead times and enhanced customer satisfaction.

Custom Solutions

heavy duty extension springs suppliers

Many leading suppliers recognize that not all applications are the same. As such, customization is often a necessity in the manufacturing of heavy-duty extension springs. Suppliers should offer services that allow for the design and production of springs based on unique specifications, materials, and performance requirements. By collaborating closely with clients, these suppliers can ensure that the springs meet their exact needs concerning load capacity, dimensional specifications, and operating environments.

Quality Assurance and Testing

Quality assurance is another critical aspect of choosing a supplier for heavy-duty extension springs. Reputable suppliers will conduct rigorous testing to ensure that their springs meet industry standards and performance guidelines. Testing methods may include load testing, fatigue testing, and dimensional inspections, providing clients with confidence in the durability and reliability of the springs. Certifications and compliance with industry regulations are also indicators of a quality supplier, as they assure customers of the integrity of the products.

Sustainable Practices

As industries become increasingly focused on sustainability, finding suppliers that prioritize eco-friendly manufacturing practices is essential. Sustainable suppliers often use recyclable materials and implement energy-efficient production methods. Choosing a supplier with a commitment to sustainability can provide an additional level of assurance, aligning with a growing trend towards corporate social responsibility.

Conclusion

Finding the right supplier for heavy-duty extension springs is crucial for ensuring the performance and reliability of the components in various applications. By evaluating suppliers based on their reputation, product range, customization capabilities, quality assurance practices, and commitment to sustainability, businesses can make informed decisions that positively impact their operations. Whether for a simple mechanism or a complex industrial application, partnering with dependable heavy-duty extension spring suppliers is key to achieving operational efficiency and product longevity. As industries evolve and demand increases, the role of robust suppliers in delivering high-quality extension springs becomes ever more significant.

share:

-

Understanding Wall Ties: Types and ImportanceNewsApr.28,2025

-

Top Products for Your Yard and Signage NeedsNewsApr.28,2025

-

The World of SpringsNewsApr.28,2025

-

Masonry Accessories: Essential for Building Strong FoundationsNewsApr.28,2025

-

Fencing Solutions for Every NeedNewsApr.28,2025

-

A Comprehensive Guide to Iron Wire for Your Construction NeedsNewsApr.28,2025

-

The Versatility of Wire Tension SpringsNewsApr.16,2025