- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Suppliers for Durable Heavy Duty Extension Springs for Industrial Applications

Heavy Duty Extension Springs Suppliers An Essential Resource for Industrial Applications

In the realm of mechanical components, springs play an indispensable role, particularly heavy duty extension springs. These springs are engineered to withstand significant loads and provide reliable performance in various industrial applications. As the demand for durable and high-performance springs grows, numerous suppliers have emerged to cater to this niche market. This article explores the importance and functionalities of heavy duty extension springs and highlights how suppliers can impact the quality and effectiveness of these critical components.

Understanding Heavy Duty Extension Springs

Heavy duty extension springs are coiled metal components that are designed to absorb and store energy when stretched. Unlike compression springs, which work by being compressed, extension springs operate under tension. Their primary function is to return to their original shape after being extended. This characteristic makes them ideal for a wide array of applications, ranging from automotive and aerospace industries to machinery and household devices.

The construction of these springs often involves high-carbon steel or stainless steel to ensure they can endure harsh conditions. The choice of material significantly affects the spring’s strength, longevity, and ability to perform under specific environmental conditions. Quality suppliers understand the importance of material selection and often provide customized solutions tailored to their customers’ needs.

The Importance of Quality Suppliers

When it comes to sourcing heavy duty extension springs, the choice of supplier is critical. Quality suppliers not only provide high-grade springs but also offer a range of services that can be beneficial to manufacturers and other industries. Here are several reasons why choosing the right supplier is vital

1. Product Quality The durability and reliability of extension springs depend significantly on the manufacturing processes employed by the supplier. A reputable supplier ensures that their springs are made with stringent quality control measures, including material verification, fatigue testing, and dimensional accuracy.

2. Customization Different applications require different specifications. Quality suppliers often offer customization options, allowing customers to specify dimensions, materials, coatings, and spring rates. This ability to tailor the product ensures that customers receive springs that meet their unique requirements.

3. Expertise and Support Established suppliers usually possess extensive knowledge about spring technology and can provide valuable advice to clients. This support may include recommendations on spring selection, installation, and maintenance, aiding customers in making informed decisions.

4. Timely Delivery In industrial operations, downtime can be costly. Reputable suppliers understand the importance of timely delivery and often maintain efficient logistics and inventory management systems to ensure that clients receive their products when needed.

heavy duty extension springs suppliers

5. Cost-Effectiveness While it might be tempting to opt for the cheapest supplier, investing in quality springs from reliable sources can lead to long-term savings. High-quality springs have a longer life span, lower failure rates, and reduced maintenance costs.

Considerations When Choosing a Supplier

When looking for heavy duty extension springs suppliers, businesses should consider several factors

1. Reputation Researching potential suppliers’ reputations is crucial. Customer reviews, testimonials, and case studies can provide insights into a supplier’s reliability and quality.

2. Certifications Look for suppliers that meet industry standards and hold relevant certifications. This not only indicates quality but also shows a commitment to maintaining high production standards.

3. Range of Products A supplier that offers a wide range of spring types and sizes may be beneficial, especially for businesses with varying needs.

4. Customer Service Evaluate the supplier’s customer service capabilities. Responsive and knowledgeable support can make a significant difference throughout the purchasing process.

5. Pricing and Warranty Compare pricing structures, but also consider warranty offerings. A solid warranty can provide peace of mind regarding product performance.

Conclusion

Heavy duty extension springs are critical components in various industries, and choosing the right supplier is essential for ensuring quality and performance. Businesses that invest time in finding reputable suppliers will ultimately benefit from enhanced product functionality, reduced downtimes, and long-term cost savings. In a market where reliability and durability are paramount, partnering with the right heavy duty extension springs suppliers can provide a competitive edge and ensure operational success.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

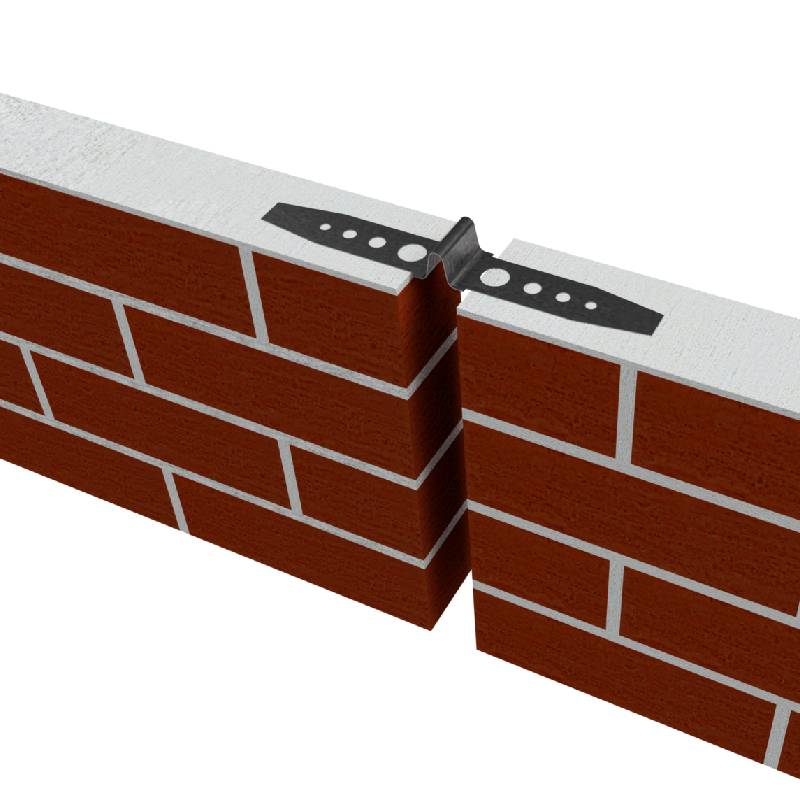

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025