- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

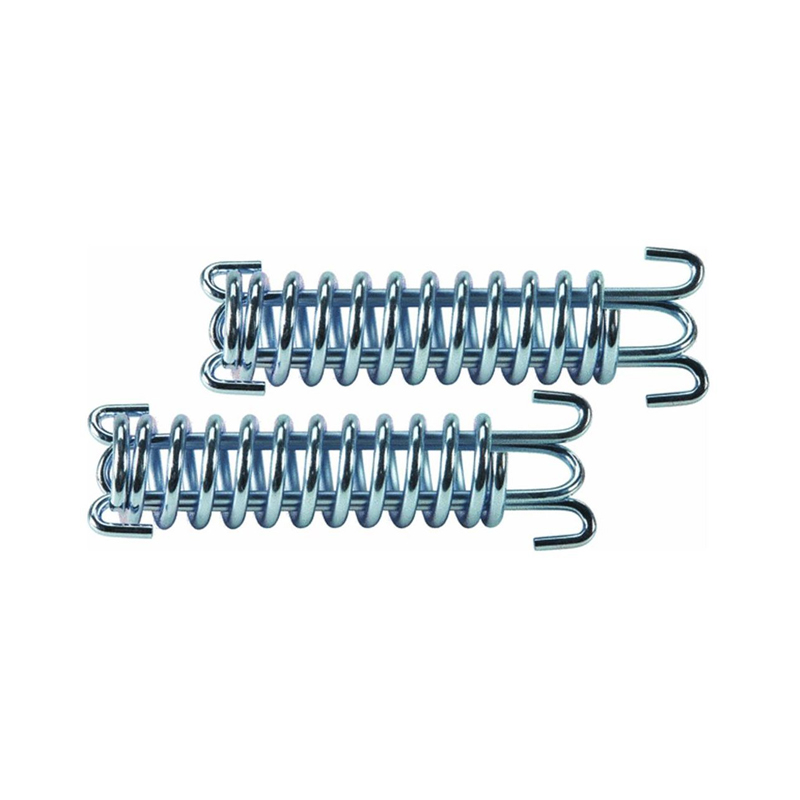

heavy duty compression springs

Heavy Duty Compression Springs An Overview

Compression springs are essential components in numerous mechanical assemblies, providing resistance and support under compression. Among these, heavy duty compression springs play a crucial role in applications that demand high load-bearing capacities, durability, and resilience. This article delves into the characteristics, applications, manufacturing processes, and advantages of heavy duty compression springs.

Understanding Heavy Duty Compression Springs

Heavy duty compression springs are designed to withstand substantial forces and stresses. These springs are typically made from high-grade materials such as stainless steel, carbon steel, or alloy steel, which enhances their strength and longevity. The robustness of these springs is characterized by their wire diameter, coil diameter, and the number of active coils.

The design of heavy duty compression springs allows them to compress and deform under load, storing potential energy that is released when the force is removed. This unique property makes them invaluable in various industries, from automotive to aerospace, and even in consumer products.

Key Characteristics

1. Dimensions and Design Heavy duty compression springs come in various sizes and configurations. The coil diameter can vary significantly, allowing for a wide range of applications. The design is often customized to meet the specific requirements of the project, including the length, number of coils, and overall strength.

2. Material Selection The choice of material is crucial for the performance of these springs. Common materials include high tensile strength steel, which provides excellent fatigue resistance, and stainless steel for applications where corrosion is a concern. The treatment of the materials, such as shot peening, helps improve fatigue life and overall durability.

3. Load Capacity Heavy duty compression springs are engineered to handle higher loads than standard springs. This makes them suitable for applications that require extra strength, such as heavy machinery, industrial equipment, and safety mechanisms.

Applications of Heavy Duty Compression Springs

Due to their robust design and high load capacity, heavy duty compression springs are utilized in numerous fields

1. Automotive Industry They are commonly found in shock absorbers, suspension systems, and engine valve assemblies. Their ability to absorb shocks and provide stability is essential for vehicle performance.

2. Manufacturing In industrial settings, these springs are used in assembly lines and conveyor systems to maintain tension and control movement.

heavy duty compression springs

3. Aerospace The aerospace sector relies on heavy duty compression springs for applications that require reliability and durability under extreme conditions, such as landing gear and control systems.

4. Medical Devices Heavy duty compression springs are also used in medical equipment, ensuring precision and safety in devices like wheelchairs and hospital beds.

5. Consumer Products Many household items, such as mattresses and recliners, incorporate heavy duty compression springs to provide comfort and support.

Manufacturing Process

The manufacturing of heavy duty compression springs involves several steps

1. Design and Engineering Initial design considerations take into account the intended application, load requirements, and material selection. Advanced software and simulations help optimize the spring's performance.

2. Wire Forming The selected wire is shaped into coils using specialized machinery. Precision is key here, as deviations can affect the spring's performance.

3. Heat Treatment After forming, the springs undergo heat treatment to enhance their mechanical properties. This process improves strength and resilience, ensuring they can handle high loads without deforming.

4. Finishing The final steps include surface finishing treatments, which may involve coating or plating to protect against corrosion and wear.

Advantages of Heavy Duty Compression Springs

- Durability Their robust construction ensures a long service life, even under extreme conditions. - High Load Capacity They can support heavier weights than regular compression springs, making them ideal for demanding applications. - Customizability Available in various sizes and configurations, these springs can be tailored to meet specific requirements.

In conclusion, heavy duty compression springs are vital components in many mechanical systems. Their ability to withstand high loads and harsh conditions while providing reliable performance makes them indispensable across various industries. Understanding their characteristics, manufacturing processes, and applications helps engineers and designers create effective solutions that leverage the strengths of these springs.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025