- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 14, 2025 02:30

Back to list

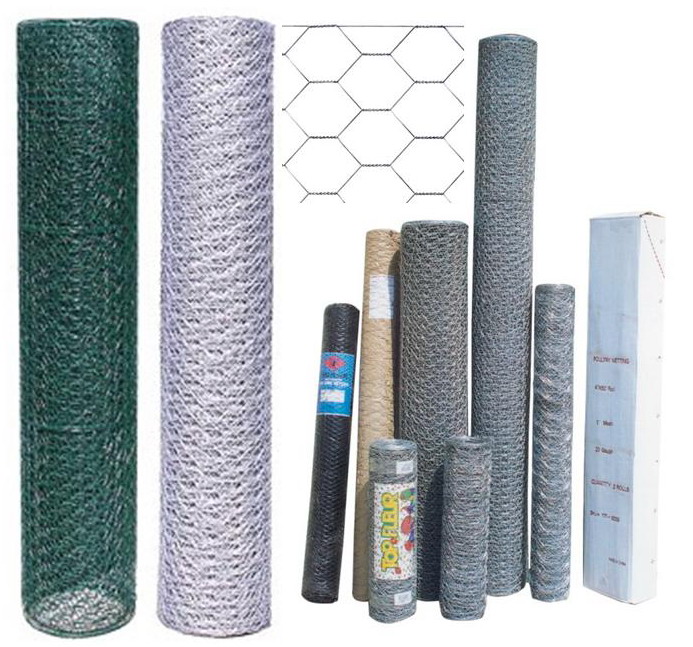

grid fencing

Galvanized wire grid panels have emerged as indispensable components across various industries, recognized for their robustness, versatility, and long-lasting qualities. From industrial applications to home improvement projects, these panels offer multifaceted solutions that cater to both practical and aesthetic needs.

Galvanized wire grid panels further establish credibility through their trustworthy track record in varied industries. Businesses across the spectrum, from logistics to horticulture, turn to these panels for solutions that demand not just robustness but also adaptability. In warehousing, for instance, they can be used as partitions or shelving to maximize space efficiency, ensuring robust support for heavy loads. Meanwhile, in horticulture, they provide excellent support structures for plant growth, standing up to the challenge of outdoor environmental exposure. Moreover, the environmental footprint of galvanized wire grid panels is another aspect awarding them a trustworthy reputation. The recycling potential of galvanized materials contributes to sustainability efforts, an increasingly significant factor for eco-conscious consumers and businesses alike. The panels, being recyclable, play a part in the global initiative to reduce waste and promote sustainable material use. When the service life of these panels ends, they can be recycled, therefore, re-entering the production cycle and minimizing environmental impact. Galvanized wire grid panels represent an amalgamation of experience, expertise, authority, and trustworthiness, making them a preferred choice in a plethora of settings. Their capacity to endure, combined with their adaptability and compliance with global standards, highlights their undeniable utility and efficacy. As industries continue to evolve and demand higher standards of material performance and sustainability, galvanized wire grid panels are set to remain at the forefront, ensuring that they are not only part of contemporary solutions but also pioneers in future innovations.

Galvanized wire grid panels further establish credibility through their trustworthy track record in varied industries. Businesses across the spectrum, from logistics to horticulture, turn to these panels for solutions that demand not just robustness but also adaptability. In warehousing, for instance, they can be used as partitions or shelving to maximize space efficiency, ensuring robust support for heavy loads. Meanwhile, in horticulture, they provide excellent support structures for plant growth, standing up to the challenge of outdoor environmental exposure. Moreover, the environmental footprint of galvanized wire grid panels is another aspect awarding them a trustworthy reputation. The recycling potential of galvanized materials contributes to sustainability efforts, an increasingly significant factor for eco-conscious consumers and businesses alike. The panels, being recyclable, play a part in the global initiative to reduce waste and promote sustainable material use. When the service life of these panels ends, they can be recycled, therefore, re-entering the production cycle and minimizing environmental impact. Galvanized wire grid panels represent an amalgamation of experience, expertise, authority, and trustworthiness, making them a preferred choice in a plethora of settings. Their capacity to endure, combined with their adaptability and compliance with global standards, highlights their undeniable utility and efficacy. As industries continue to evolve and demand higher standards of material performance and sustainability, galvanized wire grid panels are set to remain at the forefront, ensuring that they are not only part of contemporary solutions but also pioneers in future innovations.

share:

Next:

Latest news

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025