- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Jan . 17, 2025 01:09

Back to list

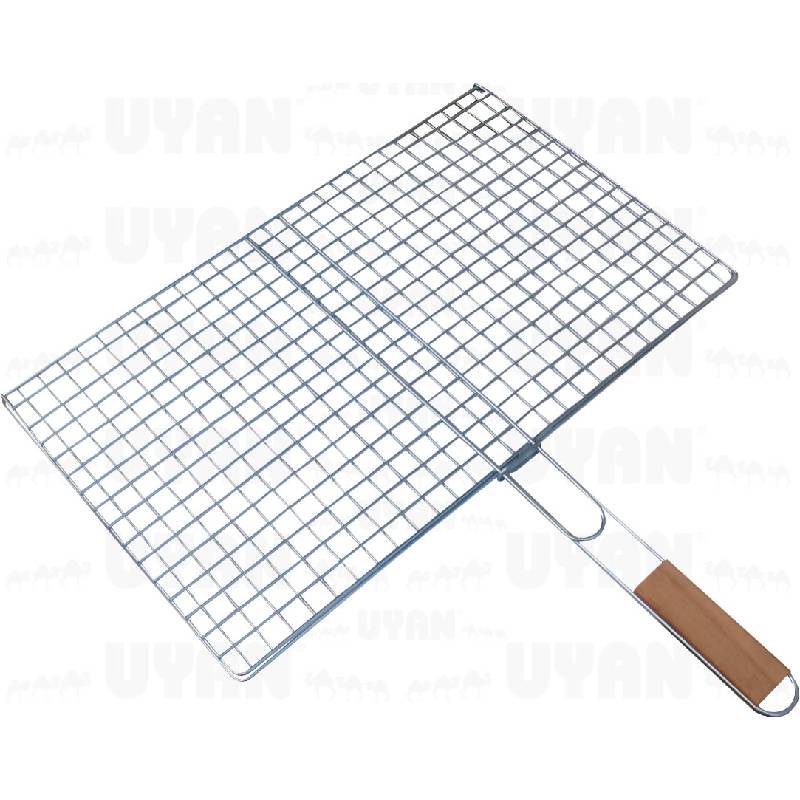

galvanized metal wire

Galvanized metal wire stands as a cornerstone in various industries, offering a blend of durability, resistivity, and versatility that few materials can match. Its unique properties arise from the galvanization process, which involves coating the wire with a layer of zinc to protect it against corrosion. This seemingly simple process instills an extraordinary resilience in the wire, making it a trusted material for countless applications.

Galvanized metal wire's ecological benefits also warrant attention. The durability of the material contributes to less frequent replacements, reducing waste and the environmental footprint associated with production cycles. Furthermore, galvanized coating can be recycled alongside metal core materials, aligning with the circular economy principles. This recyclability fosters a sustainable lifecycle for the metal wire, an increasingly critical factor as industries shift towards greener practices. From a technical standpoint, understanding the nuances of wire gauge and tensile strength is essential for selecting the appropriate galvanized wire for specific tasks. Engineers and project managers benefit greatly from the wire’s customizable attributes, which can be tailored to precise specifications without sacrificing its advantageous properties. This expertise translates into informed decision-making that optimizes performance and cost-efficiency. In a marketplace crowded with alternatives, the authoritative choice for many remains galvanized metal wire due to its demonstrated trustworthiness over decades of use. It stands as a testament not only to human ingenuity but also to the strategic use of resources, substantiating any project’s claims to quality and performance. Stakeholders across industries continue to rely on its proven track record, reinforcing the wire’s reputable status as a material that transcends expectations and adapts to evolving demands. The ongoing evolution of technology and industry practices suggests an exciting future for galvanized metal wire, with innovations geared towards enhancing its already remarkable properties. As industries pivot towards more sustainable and resilient solutions, this material is likely to gain even greater prominence, not just as a traditional choice but as a forward-facing component of next-generation infrastructures. While conventional uses of galvanized metal wire remain vital, exploring its potential in new applications could unlock further possibilities. As the world encounters new challenges, from climate change to technological advancements, galvanized wire's enduring reliability ensures it remains a key player in providing solutions that are as effective as they are adaptable.

Galvanized metal wire's ecological benefits also warrant attention. The durability of the material contributes to less frequent replacements, reducing waste and the environmental footprint associated with production cycles. Furthermore, galvanized coating can be recycled alongside metal core materials, aligning with the circular economy principles. This recyclability fosters a sustainable lifecycle for the metal wire, an increasingly critical factor as industries shift towards greener practices. From a technical standpoint, understanding the nuances of wire gauge and tensile strength is essential for selecting the appropriate galvanized wire for specific tasks. Engineers and project managers benefit greatly from the wire’s customizable attributes, which can be tailored to precise specifications without sacrificing its advantageous properties. This expertise translates into informed decision-making that optimizes performance and cost-efficiency. In a marketplace crowded with alternatives, the authoritative choice for many remains galvanized metal wire due to its demonstrated trustworthiness over decades of use. It stands as a testament not only to human ingenuity but also to the strategic use of resources, substantiating any project’s claims to quality and performance. Stakeholders across industries continue to rely on its proven track record, reinforcing the wire’s reputable status as a material that transcends expectations and adapts to evolving demands. The ongoing evolution of technology and industry practices suggests an exciting future for galvanized metal wire, with innovations geared towards enhancing its already remarkable properties. As industries pivot towards more sustainable and resilient solutions, this material is likely to gain even greater prominence, not just as a traditional choice but as a forward-facing component of next-generation infrastructures. While conventional uses of galvanized metal wire remain vital, exploring its potential in new applications could unlock further possibilities. As the world encounters new challenges, from climate change to technological advancements, galvanized wire's enduring reliability ensures it remains a key player in providing solutions that are as effective as they are adaptable.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025