- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

galvanized binding wire

The Versatility and Applications of Galvanized Binding Wire

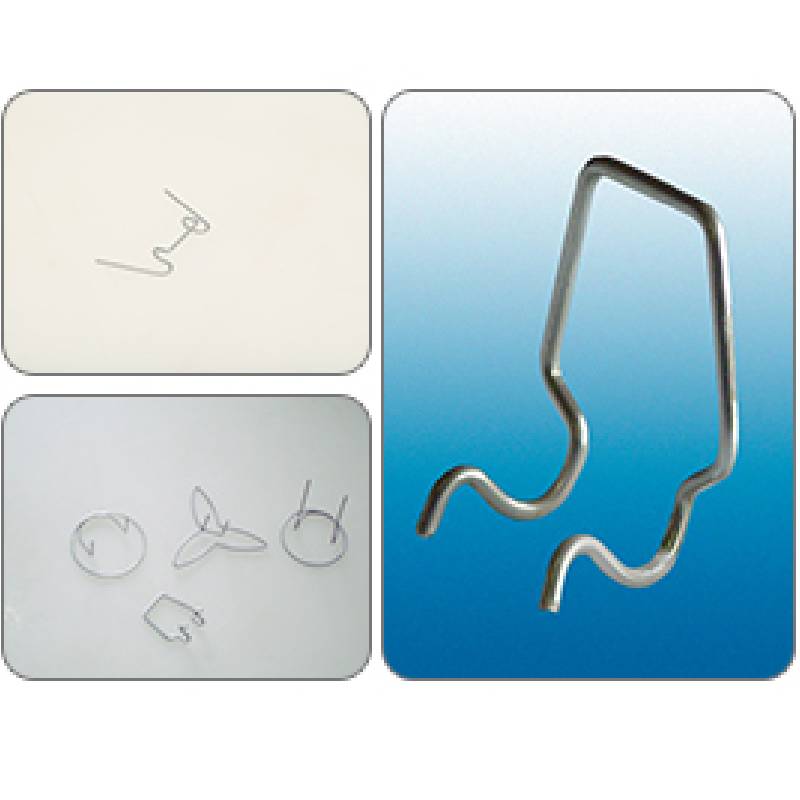

Galvanized binding wire has become a staple in various industries due to its remarkable properties and versatility. This type of wire, coated with a layer of zinc to prevent rust and corrosion, is used extensively in construction, agriculture, and home improvement projects. The unique combination of strength and flexibility makes galvanized binding wire an essential tool for both professionals and DIY enthusiasts.

One of the primary characteristics of galvanized binding wire is its corrosion resistance. The zinc coating acts as a protective barrier against moisture, which is especially crucial in outdoor and exposed environments. This quality ensures the longevity of the wire, making it ideal for use in various applications where exposure to the elements is a concern. Whether securing garden structures, crafting fences, or supporting plants, galvanized binding wire can withstand harsh weather conditions, ensuring durability and reliability.

In the construction industry, galvanized binding wire plays a critical role in reinforcing structures. It is commonly used to tie rebar and mesh together before pouring concrete, ensuring that the materials hold their shape and provide the necessary strength to withstand loads. The ability of the wire to maintain its shape while securing materials tightly makes it an invaluable asset on construction sites. Furthermore, it is lightweight and easy to handle, allowing for quick and efficient applications.

In agricultural settings, galvanized binding wire is highly utilized for constructing fences and trellises

. Farmers and gardeners rely on this wire to support plants and establish barriers that keep livestock contained. The wire’s strength allows for effective tensioning, which is crucial for maintaining the integrity of structures such as grapevines and other climbing plants. Additionally, its resistance to rust ensures that it remains functional throughout different seasons, making it a preferred choice in farming practices.galvanized binding wire

Home improvement projects also benefit from the use of galvanized binding wire. It can be used creatively for various tasks, from securing items for storage to crafting innovative home decor solutions. DIY enthusiasts often find galvanized binding wire perfect for creating custom lighting fixtures, picture frames, or even decorative wall art. Its flexibility allows for bending and shaping, enabling individuals to express their creativity while ensuring the durability needed for long-lasting projects.

Moreover, the economic aspect of galvanized binding wire cannot be overlooked. It is readily available and affordable, making it accessible for both large-scale projects and small home tasks. The initial investment is minimal, especially considering its durability and the prolonged lifespan it offers, ultimately translating to cost savings over time.

Despite its many advantages, working with galvanized binding wire does require some considerations. Users should take care while cutting and bending the wire, as the galvanized coating can create sharp edges. Using proper tools and gloves can mitigate the risk of injury. Additionally, while the zinc coating effectively prevents rust, it’s essential to store unused wire in a dry environment to maintain its integrity.

In conclusion, galvanized binding wire stands out for its strength, flexibility, and ability to resist corrosion. From construction to agriculture and home improvement, its applications are diverse and beneficial. As industries continue to innovate and seek reliable materials, galvanized binding wire will undoubtedly remain a fundamental resource, supporting a wide range of projects while offering users the quality and durability they require. Its versatility continues to inspire creativity and efficiency, making it a true asset in both professional and personal endeavors.

share:

-

Understanding Wall Ties: Types and ImportanceNewsApr.28,2025

-

Top Products for Your Yard and Signage NeedsNewsApr.28,2025

-

The World of SpringsNewsApr.28,2025

-

Masonry Accessories: Essential for Building Strong FoundationsNewsApr.28,2025

-

Fencing Solutions for Every NeedNewsApr.28,2025

-

A Comprehensive Guide to Iron Wire for Your Construction NeedsNewsApr.28,2025

-

The Versatility of Wire Tension SpringsNewsApr.16,2025