- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Jan . 16, 2025 05:42

Back to list

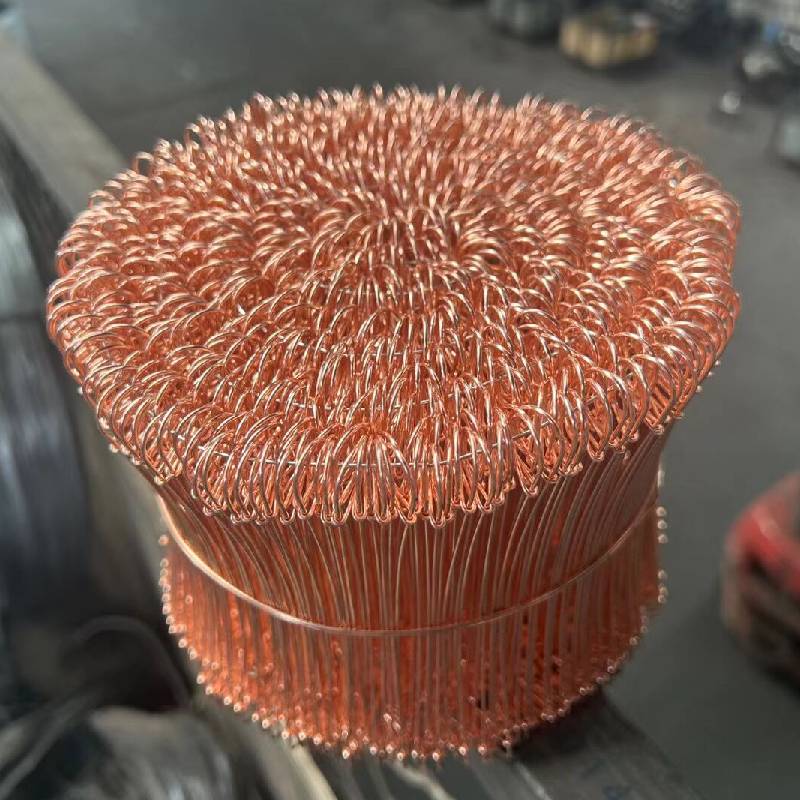

Galvanized iron wire

Galvanized binding wire has long been recognized as a cornerstone material across multiple industries, including construction, agriculture, and crafts. Its versatility, coupled with superior durability, offers a wide array of applications, making it indispensable for projects that require strength and reliability.

From an authoritative perspective, leading manufacturers maintain ISO certification and compliance with international quality standards, further instilling confidence in their products. Engineers and construction managers worldwide trust these brands, knowing that the galvanized binding wire they produce can stand the test of time. This assurance allows project coordinators to focus on the development of their projects without the worry of underlying material failure. Trustworthiness is central to galvanized binding wire's widespread use. Users often choose particular brands based on past performance and recommendations within the industry. Anecdotal evidence from seasoned professionals highlights instances where lesser quality alternatives have failed, causing project delays and increased costs. Consequently, a reputable source of galvanized binding wire is not just preferred but vital to maintaining timelines and budgets. In summary, galvanized binding wire offers an unmatched combination of strength, durability, and resistance to elements, making it essential for various applications across different industries. Its reliability is rooted in the expertise of its manufacturers and the trust it has earned from professionals across sectors. As industries continue to evolve, the demand for high-quality, reliable materials like galvanized binding wire will remain a constant, addressing both current needs and future engineering challenges.

From an authoritative perspective, leading manufacturers maintain ISO certification and compliance with international quality standards, further instilling confidence in their products. Engineers and construction managers worldwide trust these brands, knowing that the galvanized binding wire they produce can stand the test of time. This assurance allows project coordinators to focus on the development of their projects without the worry of underlying material failure. Trustworthiness is central to galvanized binding wire's widespread use. Users often choose particular brands based on past performance and recommendations within the industry. Anecdotal evidence from seasoned professionals highlights instances where lesser quality alternatives have failed, causing project delays and increased costs. Consequently, a reputable source of galvanized binding wire is not just preferred but vital to maintaining timelines and budgets. In summary, galvanized binding wire offers an unmatched combination of strength, durability, and resistance to elements, making it essential for various applications across different industries. Its reliability is rooted in the expertise of its manufacturers and the trust it has earned from professionals across sectors. As industries continue to evolve, the demand for high-quality, reliable materials like galvanized binding wire will remain a constant, addressing both current needs and future engineering challenges.

share:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025