- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Leading Manufacturers of High-Quality Flat Wire Springs for Various Applications

Understanding Flat Wire Springs and Their Manufacturers

Flat wire springs are essential components in various mechanical devices, providing the necessary force and functionality in applications ranging from automotive to electronics. Unlike traditional round wire springs, flat wire springs are made from flat wire stock, offering advantages in terms of space efficiency, strength, and customizability. This article explores the characteristics of flat wire springs, the manufacturing process, and the importance of choosing the right manufacturer.

Characteristics of Flat Wire Springs

Flat wire springs possess unique characteristics that set them apart from other types of springs. Their flat design allows for a larger surface area, which can enhance the spring's overall performance. The increased surface area contributes to a higher load-bearing capacity and improved fatigue resistance, making them suitable for high-stress applications where reliability is crucial.

Another significant advantage of flat wire springs is their versatility in design. Manufacturers can create springs in various shapes, sizes, and thicknesses, allowing for tailored solutions that meet specific customer needs. This flexibility makes flat wire springs ideal for applications in industries such as automotive, aerospace, electronics, and medical devices.

The Manufacturing Process

The manufacturing process of flat wire springs involves several steps, starting with the selection of the appropriate materials. Flat wire can be made from various metals, including stainless steel, music wire, and alloy steel, depending on the application requirements. Once the material is selected, it is processed into flat wire through a drawing process, where the metal is reduced in thickness and flattened to the desired shape.

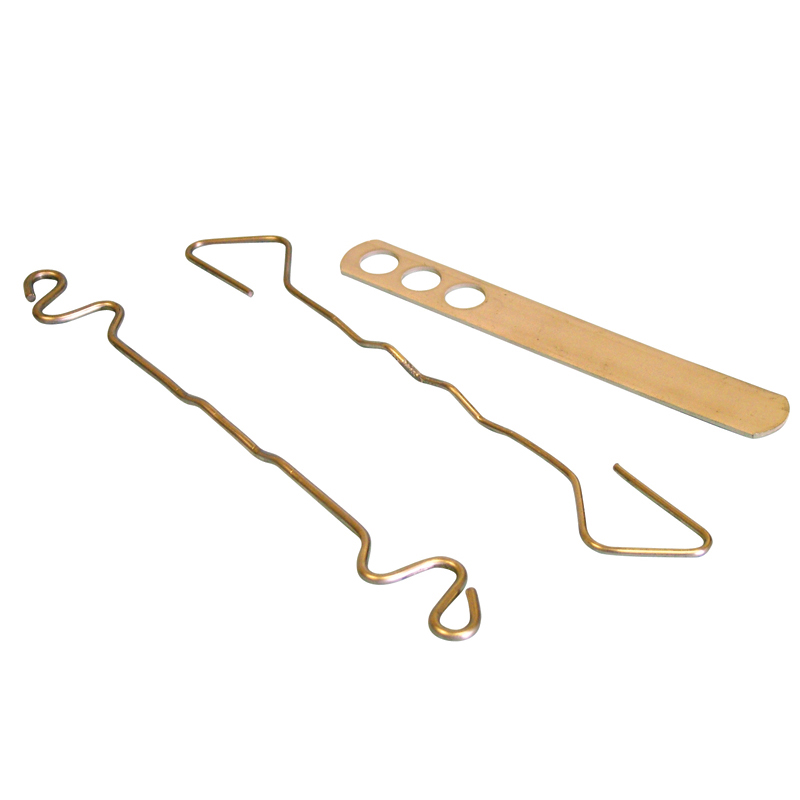

flat wire spring manufacturers

After obtaining the flat wire, manufacturers use advanced machinery to cut, shape, and form the wire into springs. This may involve processes such as bending, coiling, and heat treatment, which enhance the spring's properties and ensure it can withstand the intended load. Precision is key during this stage; any deviation can affect the spring's performance. Therefore, manufacturers often employ computer numerical control (CNC) technology to achieve the highest level of accuracy in the production process.

Importance of Choosing the Right Manufacturer

When sourcing flat wire springs, selecting the right manufacturer is essential for ensuring quality and performance. A reputable manufacturer will have a proven track record, advanced manufacturing capabilities, and a commitment to quality assurance. They should be able to provide a range of materials and customization options, allowing customers to find the perfect match for their specific needs.

Moreover, a manufacturer that follows industry standards and certifications can offer added assurance of quality. Compliance with regulations, such as ISO 9001, ensures that the manufacturing processes meet international quality management standards, which is particularly important in industries such as aerospace and medical devices, where safety and reliability are paramount.

Engaging with manufacturers that offer excellent customer service is also vital. They should be responsive to inquiries, provide clear communication throughout the production process, and be willing to collaborate with clients to address their specific requirements. This partnership can lead to innovative solutions and improved product outcomes.

Conclusion

Flat wire springs are integral components in a variety of systems, thanks to their unique characteristics and versatility. Understanding their manufacturing process and the significance of selecting the right manufacturer is crucial for businesses that rely on these components. By investing in high-quality flat wire springs from reputable manufacturers, companies can ensure their products perform reliably, meet safety standards, and ultimately satisfy their customer’s needs. In an increasingly competitive market, the right spring can make all the difference in product performance and durability.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025