- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Flat Ribbed Metal Lath Applications and Benefits in Construction and Design

Understanding Flat Rib Metal Lath A Comprehensive Guide

Flat rib metal lath has become a staple in the construction and renovation industry, renowned for its versatile applications and structural integrity. This integral building material serves as a framework for various finishes, including plaster and stucco, providing a strong bond and support that enhances the durability of walls and ceilings.

What is Flat Rib Metal Lath?

Flat rib metal lath is a thin sheet of metal, typically made from galvanized steel, that features a series of ribs or grooves. These ribs create small channels that help to improve the adhesion of plaster and other finishing materials. Unlike traditional wire lath, flat rib lath offers a flatter surface while still maintaining the structural benefits associated with lath systems. The ribs are often spaced evenly, allowing for optimal plaster coverage and reinforcement.

Advantages of Flat Rib Metal Lath

There are several advantages to using flat rib metal lath in construction projects

1. Durability One of the primary benefits of flat rib metal lath is its durability. The metal is resistant to warping, rotting, and pests, ensuring that the underlying structure remains intact over time.

2. Lightweight Despite its strength, flat rib metal lath is relatively lightweight, making it easy to handle and install. This characteristic reduces labor costs and simplifies logistics on the job site.

3. Versatility Flat rib metal lath can be used in various applications, ranging from interior walls to exterior facades. It is suitable for both residential and commercial projects, allowing designers and builders the flexibility to integrate it into diverse architectural styles.

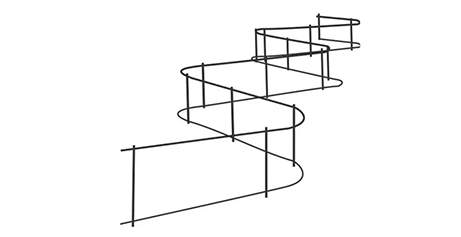

flat rib metal lath

4. Enhanced Adhesion The ribbed design of the lath promotes better adhesion for plaster and stucco finishes. This results in less cracking and peeling over time, which is crucial in maintaining the aesthetic appeal and structural integrity of the surface.

5. Fire Resistance Being made of metal, flat rib lath is inherently fire-resistant. This quality is particularly important in construction, where compliance with safety codes is essential.

Applications

Flat rib metal lath is commonly used in several applications, including

- Exterior Stucco Systems It forms a robust base for stucco, ensuring that the finish adheres properly while providing drainage and reducing moisture retention. - Interior Plastering In interior applications, flat rib lath supports various plaster finishes, creating smooth surfaces that can be painted or decorated. - Soundproofing Solutions In some cases, flat rib lath is incorporated into soundproofing strategies, assisting in the reduction of noise transmission in multi-family dwellings and commercial buildings.

Installation Considerations

Installing flat rib metal lath requires careful attention to detail to maximize its benefits. The lath should be attached to the framing securely using appropriate fasteners, ensuring that the ribs are aligned correctly to promote even plaster application. It's essential to avoid leaving gaps between the lath panels, as this can lead to weak points in the finish and compromised structural integrity.

Conclusion

Flat rib metal lath is a valuable resource in modern construction, offering a blend of durability, versatility, and ease of installation. Its unique ribbed design enhances adhesion for plaster and stucco finishes, making it an ideal choice for a variety of building projects. As construction techniques continue to evolve, the importance of materials like flat rib metal lath will undoubtedly remain strong, underpinning the integrity and aesthetics of architectural designs for years to come. Whether you are a homeowner, contractor, or architect, understanding the benefits and applications of flat rib metal lath is essential for making informed decisions in your building projects.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025