- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mar . 07, 2025 04:48

Back to list

helical compression spring

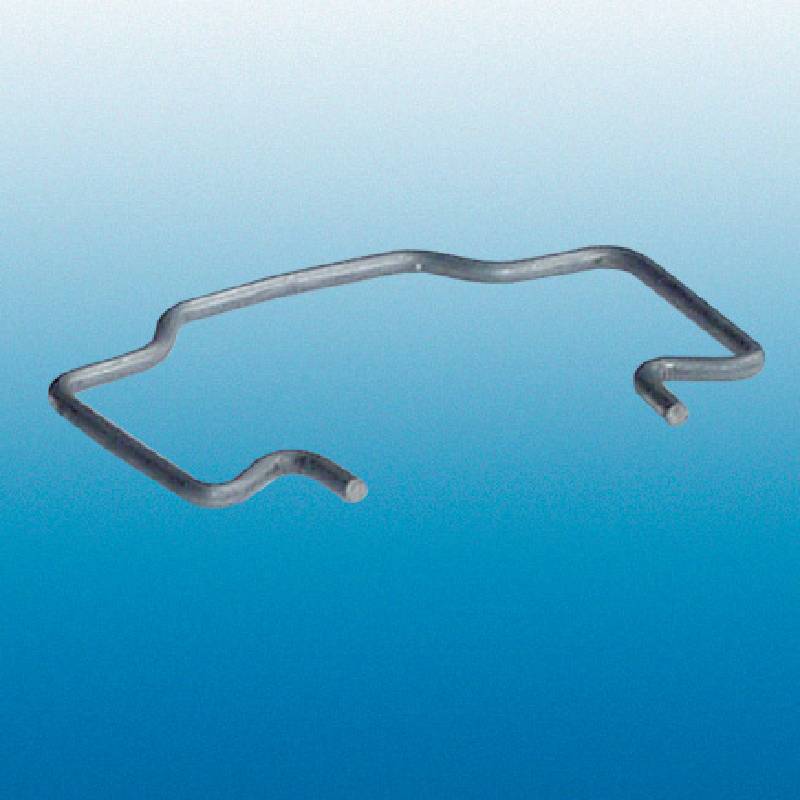

Flanged compression springs are essential yet often overlooked components in engineering and manufacturing industries. These springs are vital for diverse applications, offering unique advantages over standard compression springs. Their flanged design provides enhanced stability and load distribution, serving industries ranging from automotive to electronics.

From an engineering perspective, understanding the load-deflection properties of flanged compression springs is crucial. Their unique design allows for a more linear load-bearing capacity, making them ideal for applications requiring precise force application, such as robotic actuation mechanisms. This linear characteristic ensures consistent performance even under varied operational conditions. Flanged compression springs also find extensive use in renewable energy sectors. Wind turbines, which demand reliable and durable components to maximize uptime and efficiency, utilize these springs in their braking systems. Here, the springs play a pivotal role in regulating rotor speed, ensuring energy transmission without mechanical overloads or failures. Choosing the right supplier for flanged compression springs is paramount. An experienced supplier offers more than just a product; they provide comprehensive support, from initial design consultation to post-installation maintenance advice. Engaging with a supplier renowned for their technical support and expertise can significantly enhance project outcomes. Such suppliers are often at the forefront of technological advancements, continually updating their product offerings to align with the latest industry requirements and sustainability practices. Trust in the performance of flanged compression springs also stems from rigorous testing and compliance with international standards. Manufacturers committed to quality undergo certification processes like ISO 9001 and ISO/TS 16949, which reassure clients of their dedication to excellence and reliability. Products that meet these stringent standards are proven to withstand diverse operational environments, reinforcing their reputation for durability. In summary, flanged compression springs are more than just components; they are engineering solutions integral to modern technological advancements. Their unique design and construction advantages make them indispensable in scenarios demanding high reliability and precise performance. Engaging with knowledgeable professionals and reputable suppliers ensures optimal utilization of these springs, guaranteeing both immediate and long-term benefits for diverse industrial applications.

From an engineering perspective, understanding the load-deflection properties of flanged compression springs is crucial. Their unique design allows for a more linear load-bearing capacity, making them ideal for applications requiring precise force application, such as robotic actuation mechanisms. This linear characteristic ensures consistent performance even under varied operational conditions. Flanged compression springs also find extensive use in renewable energy sectors. Wind turbines, which demand reliable and durable components to maximize uptime and efficiency, utilize these springs in their braking systems. Here, the springs play a pivotal role in regulating rotor speed, ensuring energy transmission without mechanical overloads or failures. Choosing the right supplier for flanged compression springs is paramount. An experienced supplier offers more than just a product; they provide comprehensive support, from initial design consultation to post-installation maintenance advice. Engaging with a supplier renowned for their technical support and expertise can significantly enhance project outcomes. Such suppliers are often at the forefront of technological advancements, continually updating their product offerings to align with the latest industry requirements and sustainability practices. Trust in the performance of flanged compression springs also stems from rigorous testing and compliance with international standards. Manufacturers committed to quality undergo certification processes like ISO 9001 and ISO/TS 16949, which reassure clients of their dedication to excellence and reliability. Products that meet these stringent standards are proven to withstand diverse operational environments, reinforcing their reputation for durability. In summary, flanged compression springs are more than just components; they are engineering solutions integral to modern technological advancements. Their unique design and construction advantages make them indispensable in scenarios demanding high reliability and precise performance. Engaging with knowledgeable professionals and reputable suppliers ensures optimal utilization of these springs, guaranteeing both immediate and long-term benefits for diverse industrial applications.

share:

Next:

Latest news

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025