- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

extension springs with loop ends

Understanding Extension Springs with Loop Ends

Extension springs are a vital component in various mechanical systems, designed to absorb and store energy when stretched. Unlike compression springs, which compress under load, extension springs elongate, exerting a force that attempts to bring them back to their original length. Their applications range from industrial machinery to everyday household items, making them a critical element in many engineering designs.

One notable feature of extension springs is the presence of loop ends. These loop ends serve as the connection points, allowing the springs to be mounted securely while ensuring proper force application and distribution. Typically, extension springs come with several types of ends, including machine hooks, cross holes, and loops, but loop ends are particularly popular due to their versatility and ease of use.

Design and Functionality of Loop Ends

Loop ends are crafted by bending the wire at each end of the spring to form a closed loop. This design provides increased stability when the spring is under tension. Unlike hooks, which may disengage if not securely fastened, loop ends ensure a more reliable connection, reducing the risk of disassembly during operation. The circular shape distributes stress across the material, minimizing the likelihood of failure under extreme loads.

When designing an extension spring with loop ends, engineers must consider the spring's wire diameter, coil diameter, the number of coils, and the overall length. These factors directly influence the spring's performance and its ability to return to its resting state after being stretched. The material used is also crucial; high-carbon steel is commonly employed for its combination of strength and elasticity, but other materials, such as stainless steel or music wire, may be selected based on specific environmental conditions and requirements.

Applications of Extension Springs with Loop Ends

extension springs with loop ends

Extension springs with loop ends find a wide array of applications across various industries. In automotive engineering, they are commonly used in hatchback mechanisms, seat mechanisms, and other interior components to provide smooth operation and reliability. In the realm of electronics, these springs assist in opening and closing mechanisms within devices, ensuring optimal functionality.

Similarly, in consumer goods, extension springs with loop ends are integral to the smooth function of everyday items such as retractable dog leashes, screen doors, and mechanical toys

. Their reliability makes them an essential component in any device that involves repetitive motion or requires a returning force.Manufacturing Considerations

The manufacturing process of extension springs with loop ends involves precise calculations and techniques to ensure quality and performance. Automation has significantly improved the efficiency of spring production, allowing for high-volume manufacturing with consistent quality. However, customization remains a critical factor, as different applications may necessitate unique specifications.

It is essential for manufacturers to engage in rigorous testing, including load testing and fatigue testing, to ensure that the springs can withstand the intended use without failure. Quality control measures must be implemented throughout the manufacturing process to prevent defects that could compromise the spring's functionality.

Conclusion

In conclusion, extension springs with loop ends play a crucial role in modern engineering and everyday applications. Their unique design and functionality cater to a diverse range of needs, making them indispensable in various fields. As technology progresses, the demand for high-quality, reliable extension springs is likely to grow, underscoring the importance of ongoing innovation in their design and manufacturing processes. Understanding the intricacies of these springs not only helps engineers create better products but also advances the overall efficiency and reliability of the machinery they serve.

share:

-

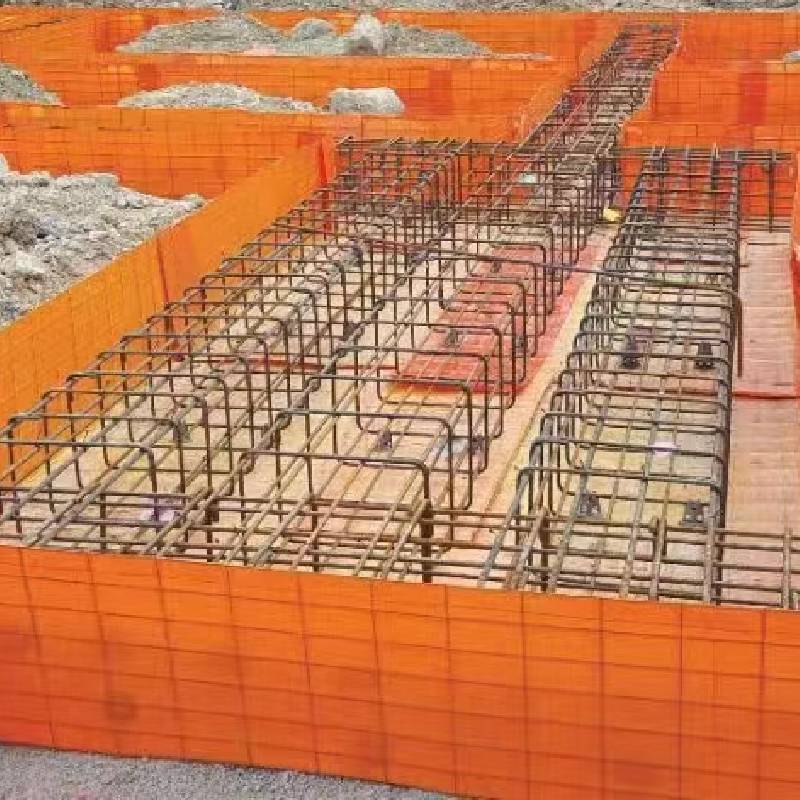

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025