- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

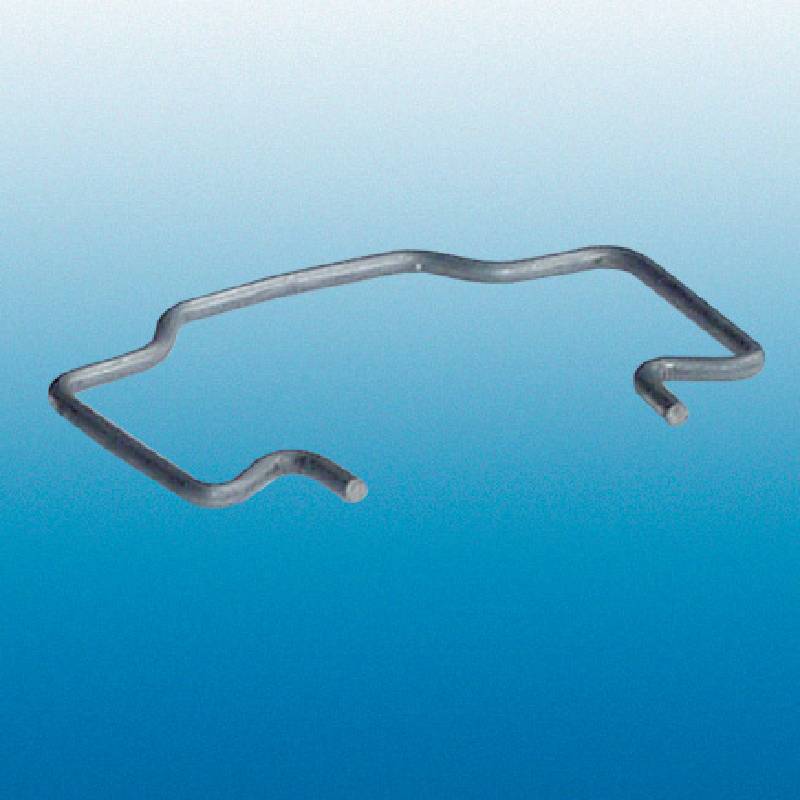

Hook-Ended Extension Springs for Enhanced Performance and Versatility in Applications

Understanding Extension Springs with Hook Ends An Essential Component for Mechanical Applications

Extension springs are vital components in various mechanical systems, providing the necessary tension that helps maintain equilibrium in machines and devices. Among the various types of extension springs, those with hook ends are particularly noteworthy. This article will explore the characteristics, applications, and advantages of extension springs with hook ends, highlighting their significance in engineering and industrial applications.

What Are Extension Springs with Hook Ends?

Extension springs are coil springs designed to absorb and store energy. They function by resisting the force that attempts to stretch them. Hook-ended extension springs feature metal hooks at either end, allowing for easy attachment to different fixtures or components. The design of these hooks ensures that the spring remains securely in place, preventing it from slipping out during operation.

Typically made from high-carbon steel, stainless steel, or other durable materials, these springs come in various sizes, diameters, and coil configurations to meet specific demands. The choice of material is crucial, as it not only affects the spring's strength and durability but also its resistance to environmental factors such as corrosion.

Applications of Extension Springs with Hook Ends

Extension springs with hook ends are versatile and can be found in a multitude of applications across various industries. Here are some common uses

1. Automotive Industry In automobiles, these springs are used in mechanisms such as trunk latches, hoods, and suspension systems. The hook ends allow for quick installation and adjustment, addressing the dynamic forces experienced during vehicle operation.

2. Home Appliances Many household devices, including washing machines and lawnmowers, utilize extension springs with hook ends. They provide the necessary tension to operate moving parts efficiently, enhancing the overall functionality of appliances.

extension springs with hook ends

4. Industrial Machinery Home to numerous applications, industrial machines make extensive use of extension springs to maintain pressure in hoppers, belts, and other components, ensuring smooth operations while minimizing wear and tear.

5. Toys and Recreational Devices Many toys incorporate extension springs within their design. The elasticity and tension provided by these springs contribute to the fun and functionality of various playthings, from simple wind-up toys to complex mechanical devices.

Advantages of Extension Springs with Hook Ends

One of the primary advantages of extension springs with hook ends is their simplicity and ease of installation. The hook design allows for quick mounting and dismounting without the need for complex mechanisms. This feature is especially beneficial in applications where frequent maintenance or adjustments are required.

Moreover, the ability to deliver high tensile strength in a compact design allows these springs to function effectively in confined spaces or limited environments. Their adaptability further extends to a range of tension levels, making them suitable for both lightweight and more demanding applications.

Another significant advantage is their durability. Made from robust materials, these springs can withstand repeated stretching and compression cycles without losing their integrity. This resilience translates to lower maintenance costs and longer service life, which is crucial for both commercial and industrial applications.

Conclusion

Extension springs with hook ends are not just simple components; they play a crucial role in the functionality and efficiency of many mechanical systems. Understanding their design, applications, and advantages can help industries make informed decisions when selecting parts for their machinery and devices. As technology advances, these springs will continue to evolve, contributing to innovations in various sectors, from automotive to aerospace and beyond. With their reliability, versatility, and ease of use, extension springs with hook ends are undeniably essential in today's fast-paced, mechanical-driven world.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025