- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Exploring the Versatility and Applications of Continuous Wire in Modern Industries and Technologies

The Intricacies of Continuous Wire Understanding Its Applications and Importance

Continuous wire is a fundamental material that plays a pivotal role in various industries ranging from manufacturing to telecommunication. It is characterized by its uninterrupted length, enabling a wide range of applications that demand reliability and consistency. This article delves into the properties, manufacturing processes, and diverse applications of continuous wire, underscoring its significance in modern technology.

Properties of Continuous Wire

Continuous wire is typically made from metals such as copper, aluminum, or steel, each offering unique properties that cater to different requirements. Copper, known for its excellent electrical conductivity, is widely used in wiring and electrical components. Aluminum, being lighter and resistant to corrosion, is preferred in applications where weight is a critical factor. Steel wires, particularly those that are high-carbon, exhibit superior strength and durability, making them ideal for structural applications.

One of the defining features of continuous wire is its uniform cross-section throughout its length, which ensures consistent performance. This property is crucial for applications that require precise tension and strength, such as in cable manufacturing and structural reinforcement. Additionally, continuous wire can be produced in various gauges and coatings, further enhancing its versatility.

Manufacturing Processes

The production of continuous wire involves several key steps, beginning with the selection of raw materials. The chosen metal is then drawn through a series of dies to achieve the desired diameter. This drawing process not only reduces the wire’s cross-section but also enhances its mechanical properties through strain hardening. Once the wire has reached its target diameter, it undergoes treatment processes such as annealing, which helps relieve stress and improve ductility.

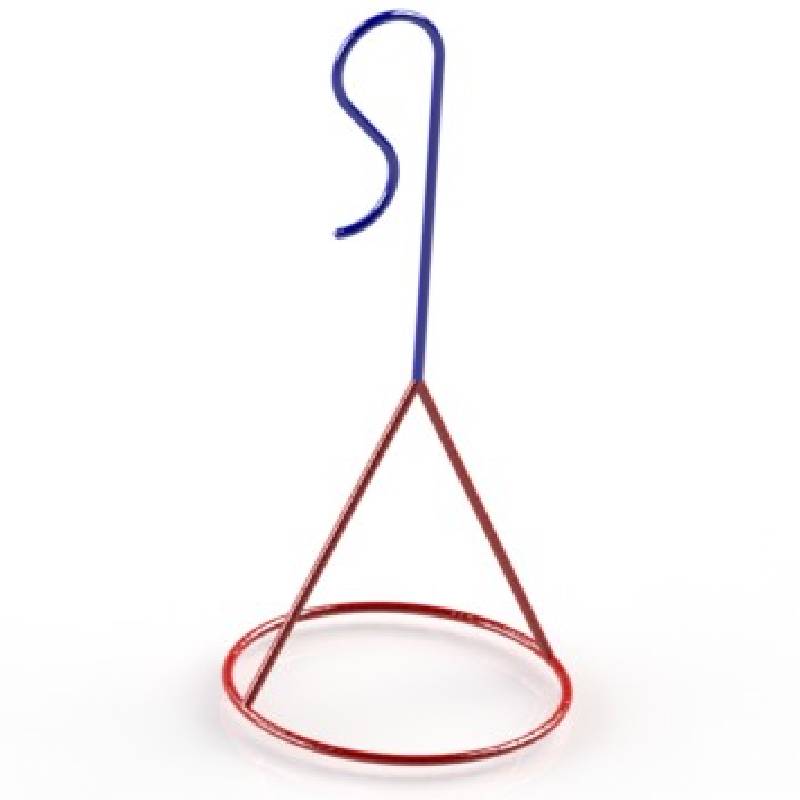

continuous wire

Another critical aspect of continuous wire manufacturing is its spooling process

. After the wire is drawn and treated, it is wound onto spools for easy handling and transportation. This process ensures that the wire can be deployed in large lengths without the need for multiple connections, minimizing the risk of failure during applications.Applications of Continuous Wire

The applications of continuous wire are vast and varied. In the electrical industry, it is used for power transmission, wiring in buildings, and in the assembly of electronic devices. The automotive sector relies on continuous wire for the manufacturing of cables and harnesses, ensuring the efficient transmission of electrical signals throughout vehicles.

In construction and civil engineering, continuous wire is utilized for reinforcing concrete structures. Steel wire, specifically, is a crucial component in making wire mesh and rebar, which enhances the tensile strength of concrete. Additionally, continuous wire finds applications in the production of springs, ropes, and cables, underscoring its importance in mechanical systems.

Moreover, in the telecommunications field, continuous wire is essential for the manufacturing of telephone and data cables. The uninterrupted nature of the wire allows for better signal integrity, which is crucial for communication devices.

Conclusion

In conclusion, continuous wire represents a vital component in numerous industries, owing to its unique properties and adaptability. From its manufacturing processes to its wide-ranging applications, understanding continuous wire is essential for anyone involved in engineering, telecommunications, or construction. As technology continues to advance, the importance of high-quality continuous wire will only grow, ensuring its place as a staple in modern production and infrastructure.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025