- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Exploring the Benefits and Applications of Welded Wire Reinforcement for Concrete Structures

Welded Wire Concrete Reinforcement Enhancing Structural Integrity

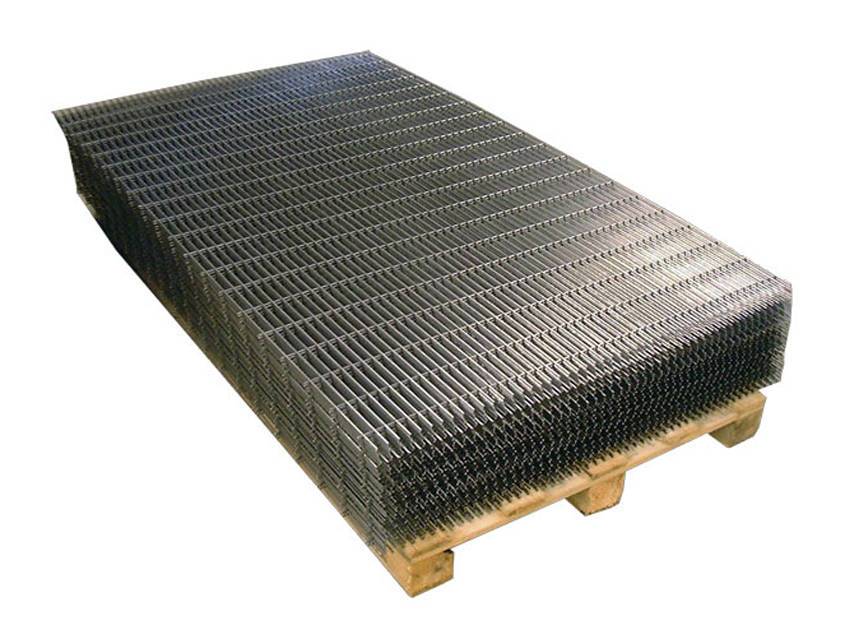

Welded wire concrete reinforcement has emerged as a pivotal innovation in the construction industry, offering an effective solution for enhancing the structural integrity of concrete infrastructures. This method involves the use of welded wire fabric, which is made up of intersecting steel wires that are welded together at regular intervals. This innovative reinforcement technique provides several advantages over traditional rebar, making it a preferred choice for various construction applications.

Welded Wire Concrete Reinforcement Enhancing Structural Integrity

Moreover, the installation process of welded wire reinforcement is significantly more efficient than traditional reinforcement methods. The pre-fabricated sheets can be easily handled and laid out on-site, reducing labor costs and construction time. This convenience is further amplified by the fact that welded wire fabrics are available in various sizes and configurations to meet different project specifications. The ability to customize these products helps contractors and engineers to optimize their designs, accommodating the unique demands of each construction project without compromising quality.

welded wire concrete reinforcement

In addition to efficiency, welded wire reinforcement offers enhanced durability. The welded joints between the wires provide increased resistance to fatigue and bending, making the concrete structure more robust against dynamic loads. This resilience is particularly valuable in regions prone to seismic activity or heavy vehicle traffic, where traditional reinforcement methods may struggle to maintain structural integrity over time. Furthermore, the corrosion resistance of welded wire, especially when combined with appropriate protective coatings, enhances the longevity of reinforced concrete structures, reducing maintenance costs and extending service life.

Environmental considerations also favor the use of welded wire reinforcement. The manufacturing process of welded wire fabric often involves less material waste compared to traditional rebar, as the sheets can be produced to precise specifications. Additionally, steel is a fully recyclable material, and the use of welded wire in construction supports sustainable building practices by reducing the overall carbon footprint associated with concrete production.

Despite these advantages, it is essential for engineers and contractors to understand the specific applications and limitations of welded wire reinforcement. While it is highly effective for slab-on-grade applications and flatwork, it may not be suitable for all scenarios, particularly in vertical applications or highly stressed elements where traditional rebar might be preferred. Proper design and engineering principles should always be applied to ensure that the reinforcement method chosen aligns with the structural requirements of the project.

In conclusion, welded wire concrete reinforcement offers a modern solution that enhances the performance and longevity of concrete structures. Its efficient installation, uniform strength distribution, and durability make it an attractive option for a variety of construction applications. As the industry continues to evolve towards more innovative and sustainable practices, welded wire reinforcement stands out as a significant advancement that promotes safer and more resilient infrastructure. Whether in residential, commercial, or civil engineering projects, this reinforcement technique is set to play a crucial role in shaping the future of construction.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025