- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

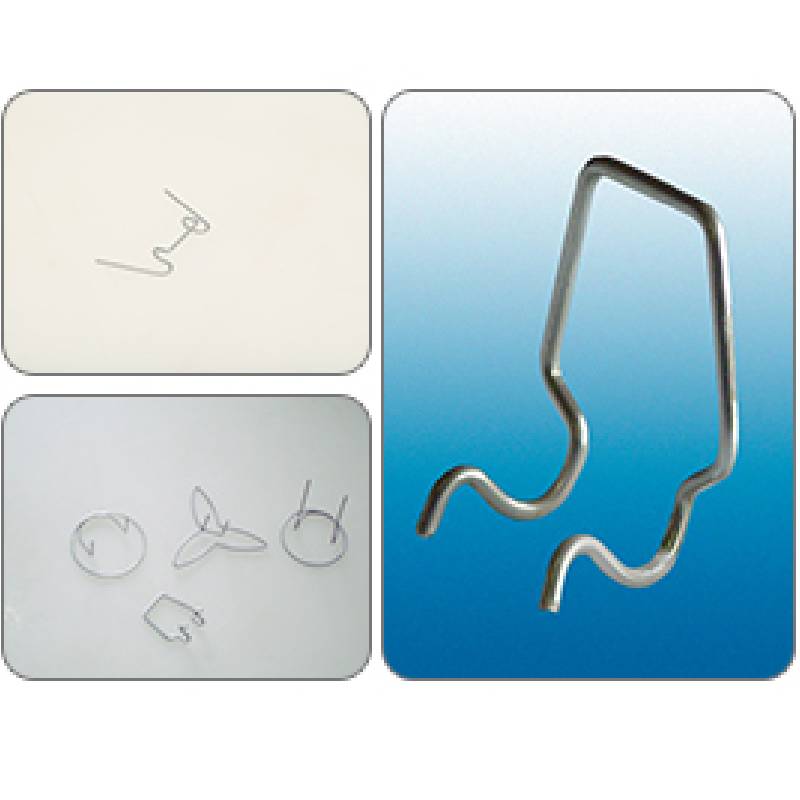

electric wire spring

The Versatility of Electric Wire Springs in Modern Applications

Electric wire springs are ingeniously crafted components that play a crucial role in a myriad of applications across various industries. These springs are made from electrically conductive wire, typically steel or copper, which allows them to serve dual purposes providing mechanical resilience and facilitating electrical connectivity. This unique combination of features has made electric wire springs increasingly popular in applications ranging from electronics to automotive engineering and even in household appliances.

One of the primary advantages of electric wire springs is their ability to store mechanical energy while conducting electrical current. This characteristic is essential in many modern devices. For instance, in electronic circuits, these springs can act as connectors that maintain a consistent tension, ensuring reliable contact between different parts of a circuit. The elasticity of the wire allows it to absorb shocks and vibrations, protecting sensitive electronic components from damage and ensuring longer operational life.

In the automotive industry, electric wire springs are often found in components such as sensors, starters, and battery connectors. Their ability to maintain electrical conductivity while adapting to the dynamic movements of a vehicle makes them indispensable. In petrol and electric vehicles alike, these springs can withstand the rigors of constant expansion and contraction due to temperature changes and engine vibrations.

The manufacturing process of electric wire springs can significantly impact their performance and durability. Advanced techniques such as precision winding and heat treatment ensure that the springs maintain their shape and functionality even under extreme conditions. Engineers often consider various factors, including wire diameter, coil pitch, and the number of turns, to customize the spring for specific applications.

electric wire spring

Another significant application of electric wire springs is in the realm of renewable energy. With the rise of solar panel technologies, these springs have been employed in tracking systems, where they can help ensure that solar panels adjust to the sun's position throughout the day. This capability maximizes energy absorption and can lead to more efficient solar power generation. Additionally, they can be used in wind turbines to connect various components while allowing for movement, ensuring reliable energy production.

Household appliances also benefit from electric wire springs. They are commonly found in devices such as washing machines, microwaves, and coffee makers. In these applications, electric wire springs not only provide mechanical support but also play a role in electrical connections that help power the device. Ensuring that these connections remain reliable and are able to handle daily use without failure is crucial for safety and functionality.

The advancements in materials science have also played a significant role in the development of electric wire springs. The introduction of new alloys and coatings can enhance conductivity, resist corrosion, and improve the overall lifespan of the components. Engineers today have a vast array of materials at their disposal, allowing for greater customization to meet the specific needs of each application.

In conclusion, electric wire springs are a testament to human ingenuity, blending mechanical properties with electrical functionality. Their versatility makes them indispensable in various sectors, from automotive and electronics to renewable energy and household appliances. As technology continues to evolve, it is likely that the applications of electric wire springs will expand even further, making them an exciting area for future innovations. With ongoing research and development, these components will not only improve in performance but also contribute to more sustainable practices across industries.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025