- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Durable and Versatile PVC Coated Binding Wire for Various Applications and Projects

Understanding PVC Coated Binding Wire Features, Applications, and Benefits

PVC coated binding wire is an essential product used across various industries for binding, securing, and organizing materials. It features a core wire made typically from galvanized steel, which is then coated with a layer of polyvinyl chloride (PVC). This combination of materials provides exceptional durability and resistance to environmental factors, making it a preferred choice for many applications. In this article, we will explore the characteristics, applications, and benefits of PVC coated binding wire.

Characteristics of PVC Coated Binding Wire

One of the most significant features of PVC coated binding wire is its robustness. The galvanized steel core offers excellent tensile strength, enabling it to withstand significant pressure without breaking or bending. The PVC coating adds an extra layer of protection against rust, corrosion, and abrasion, which is particularly important when the wire is exposed to outdoor conditions or harsh environments.

In addition to its durability, PVC coated binding wire is available in various diameters and colors. This versatility allows users to choose the right thickness for their needs, ensuring optimal performance for specific applications. The range of colors also provides aesthetic flexibility, making it suitable for both industrial and decorative purposes.

Applications of PVC Coated Binding Wire

PVC coated binding wire is utilized in numerous industries, showcasing its versatility and effectiveness. Some of the primary applications include

1. Construction In the construction industry, PVC coated binding wire is commonly used for tying rebar and securing various structural components. Its strong and durable nature ensures that the bindings remain intact during construction, contributing to the overall safety and integrity of the structures.

2. Agriculture Farmers and agricultural professionals use PVC coated wire for various purposes, including fencing, trellising plants, and securing plants to stakes. The PVC coating protects the wire from moisture and chemicals found in fertilizers and pesticides, ensuring longevity and reliability.

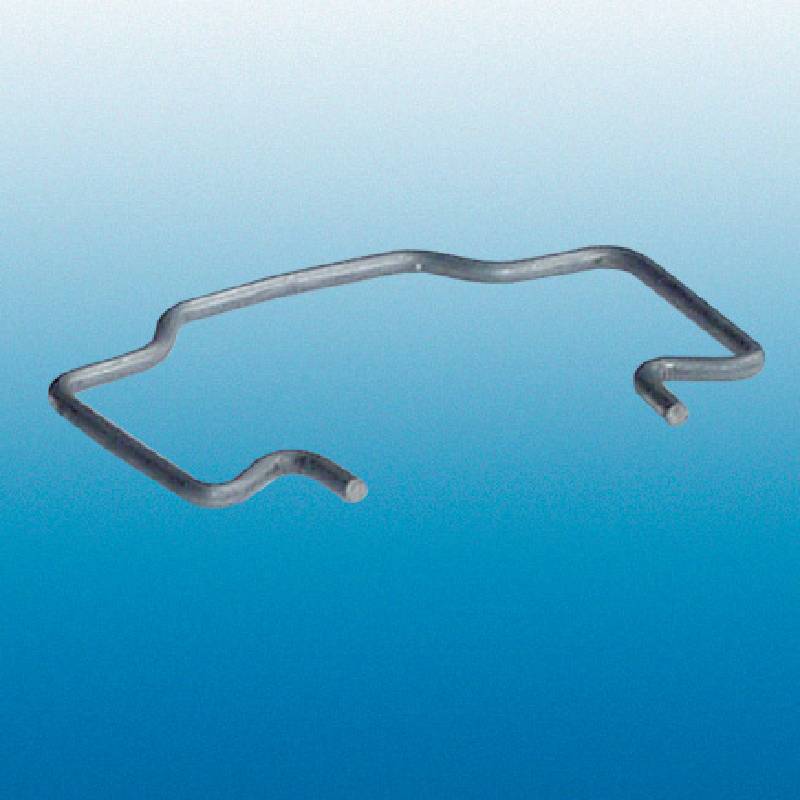

pvc coated binding wire

3. Wiring and Electrical Applications PVC coated binding wire is also utilized in the wiring of electronic devices and as harness wiring in the automotive industry. The coating provides electrical insulation, enhancing safety and effectiveness.

4. Crafting and DIY Projects Crafters and DIY enthusiasts appreciate PVC coated binding wire for its flexibility and ease of use. It can be employed in a variety of creative projects, from making decorative items to fashioning functional structures.

5. Manufacturing and Packaging In the manufacturing sector, PVC coated binding wire is used for bundling products, holding materials together during production, and packaging. Its strength ensures that products remain secure during transport and storage.

Benefits of PVC Coated Binding Wire

The benefits of using PVC coated binding wire are numerous. First and foremost, the enhanced durability and resistance to environmental factors translate to a longer service life, reducing the need for replacements and maintenance. This can lead to significant cost savings over time.

Additionally, the aesthetic appeal of various colors makes PVC coated binding wire suitable for both functional and decorative applications. In sectors where appearance matters, such as landscaping or crafting, the visual aspect can enhance the end product.

Furthermore, the ease of use and flexibility of PVC coated binding wire allows for quick installation and modification, catering to the dynamic needs of different projects.

Conclusion

In summary, PVC coated binding wire is an indispensable tool across a multitude of industries due to its durability, versatility, and aesthetic options. Whether in construction, agriculture, crafting, or manufacturing, its applications are vast and varied. The benefits it provides make it a wise investment for anyone needing a reliable binding solution. As technology evolves, we can expect further innovations in materials and applications, solidifying PVC coated binding wire's place in the market.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025