- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

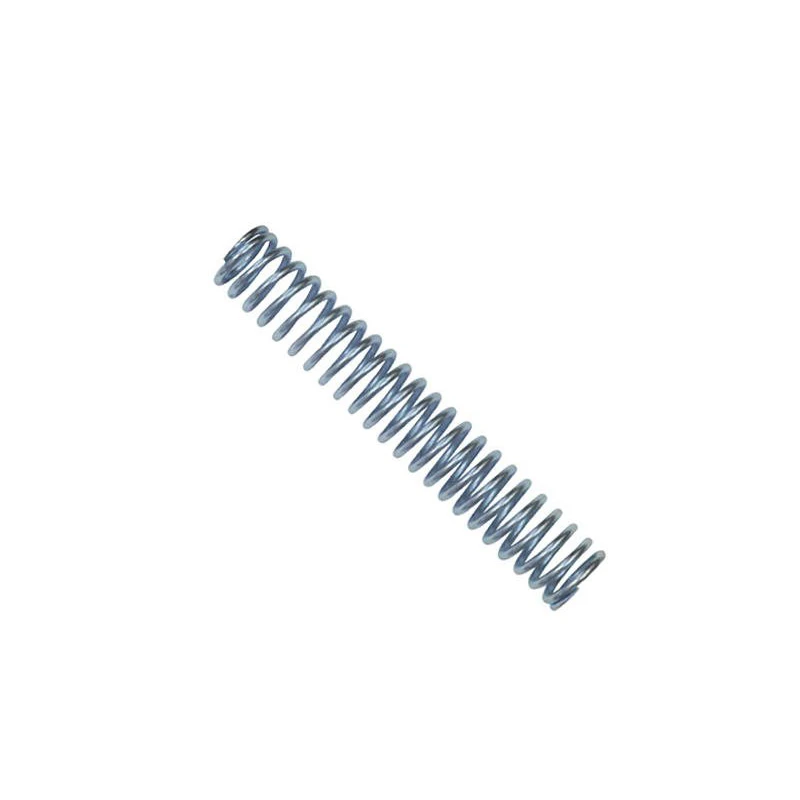

custom torsion springs

Understanding Custom Torsion Springs The Key to Precision and Flexibility

Torsion springs play a crucial role in various mechanical systems, providing the necessary force to counterbalance loads and enable rotational movements. Unlike compression or extension springs, torsion springs store energy when twisted around their axis, allowing them to return to their original shape when the force is removed. In many cases, standard torsion springs may not meet the specific needs of a project, which is where custom torsion springs come into play.

What are Custom Torsion Springs?

Custom torsion springs are specially designed springs that are manufactured to meet specific dimensions, materials, and performance criteria. These springs can be tailored in terms of wire diameter, coil diameter, number of coils, and overall length. By customizing the design, manufacturers can ensure that the springs will function optimally in their intended application, taking into account factors such as required torque, load requirements, and environmental conditions.

Why Consider Custom Solutions?

1. Precision Fit One of the primary advantages of custom torsion springs is the ability to achieve a precise fit. Standard springs may not fit the exact specifications needed for a particular application, whereas custom-made options can be designed to fit seamlessly within the mechanical system. This precision helps enhance performance, reduce wear and tear, and minimize the risk of failure.

2. Optimized Performance Every application has unique performance requirements. Custom torsion springs can be engineered to deliver specific torque values and deflection characteristics, allowing them to cater to the precise needs of machinery, vehicles, appliances, and other devices. This optimization can lead to improvements in efficiency and durability.

custom torsion springs

3. Material Selection Different applications may require different materials to ensure the longevity and reliability of the spring. Custom torsion springs can be made from a variety of materials, including stainless steel, music wire, and specialty alloys, each offering distinct properties such as corrosion resistance, strength, and flexibility. The choice of material directly impacts the spring's performance in various environments.

4. Cost-Effective Solutions Although custom springs may seem more expensive initially, they can ultimately be more cost-effective. A well-designed spring can reduce maintenance costs, minimize downtime, and improve overall system efficiency. By preventing spring breakage or malfunction, companies can avoid costly repairs and replacements in the long run.

Applications of Custom Torsion Springs

Custom torsion springs find their applications across numerous industries, including

- Automotive Used in hinges, latches, and seat mechanisms to ensure smooth operation and reliability. - Aerospace Critical for components requiring lightweight yet robust solutions that can withstand extreme conditions. - Electronics Found in devices that require precise tension, such as printers and cameras, where compact design is essential. - Home Appliances Used in items like washing machines and garage doors, where consistent performance is critical for safety and efficiency.

Conclusion

Custom torsion springs are an invaluable component for countless applications, offering tailored solutions that enhance performance, precision, and durability. When opting for custom springs, it is essential to work closely with experienced manufacturers who can help identify the specific requirements of your project, ensuring that the final product meets all necessary criteria. By investing in custom torsion springs, businesses can secure reliable, efficient, and effective mechanical solutions tailored exactly to their needs.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025