- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Custom Compression Spring Manufacturer for Tailored Solutions and Superior Quality Springs

The Role of Custom Compression Spring Manufacturers in Modern Industries

In today's fast-paced manufacturing landscape, the demand for precision-engineered components is at an all-time high. Among these components, custom compression springs play a critical role in various industries, including automotive, aerospace, electronics, and medical equipment. Custom compression spring manufacturers have emerged as vital partners for businesses seeking to enhance their product performance through tailored solutions.

Custom compression springs are designed to withstand compressive loads while also providing flexibility and durability. Unlike standard springs, which come in fixed sizes and specifications, custom springs are engineered to meet the specific requirements of a project. This customization allows manufacturers to optimize performance, reduce material waste, and improve overall product efficiency.

One of the primary advantages of working with a custom compression spring manufacturer is the opportunity for collaboration. These manufacturers often work closely with their clients to understand the unique needs of each application. By employing advanced modeling and simulation techniques, they can design springs that not only meet load specifications but also fit within spatial constraints and operate within desired cycle limits. This level of customization can significantly impact the performance and longevity of a product.

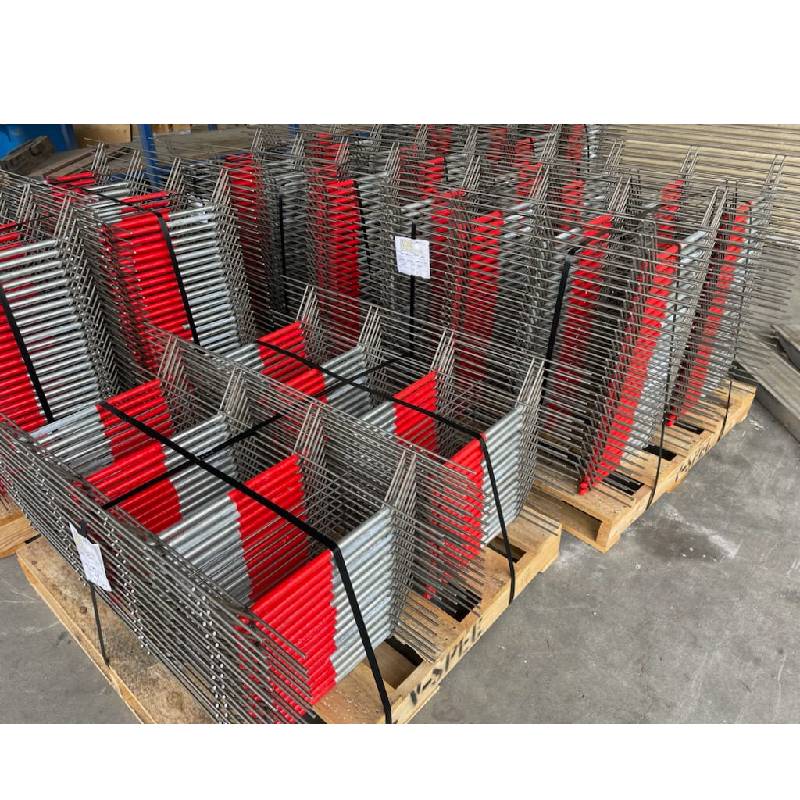

custom compression spring manufacturer

Additionally, advancements in materials science have enabled custom spring manufacturers to offer a wide range of materials, from stainless steel to specialized alloys and composite materials. This variety ensures that manufacturers can find the perfect material to meet the demands of their specific applications, whether that be resistance to corrosion, high-temperature performance, or lightweight characteristics.

Quality control is another key area where custom compression spring manufacturers excel. Reputable manufacturers implement rigorous testing protocols to ensure that each spring meets strict quality standards. This attention to detail not only minimizes the risk of failure in the field but also provides clients with confidence in the reliability of their components.

Furthermore, as industries increasingly focus on sustainability, custom compression spring manufacturers are also prioritizing eco-friendly practices. From sourcing raw materials responsibly to implementing energy-efficient manufacturing processes, many manufacturers are taking steps to reduce their environmental footprint.

In conclusion, custom compression spring manufacturers play an essential role in supporting the diverse needs of modern industries. Through collaboration, innovation, and a commitment to quality, these manufacturers enable businesses to develop products that are not only functional but also efficient and sustainable. As industries continue to evolve, the partnership between businesses and custom spring manufacturers will remain crucial for driving innovation and achieving competitive advantage.

share:

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025