- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

continuous wire

The Evolution and Applications of Continuous Wire Technology

Continuous wire technology has revolutionized various industries, providing efficient and cost-effective solutions to meet the increasing demands for high-quality materials. Unlike traditional wire manufacturing, continuous wire production involves a streamlined process that allows for the uninterrupted creation of wire through advanced machinery. This innovation not only enhances production efficiency but also ensures better control over the wire’s mechanical properties.

The process begins with raw materials, typically drawn from high-quality metals such as copper or aluminum. These metals are continuously fed into a wire drawing machine, where they are stretched and shaped into thin strands. This method allows for a consistent diameter and improved strength due to the reduction of defects and uniformity in the material structure. As a result, continuous wire exhibits superior performance characteristics, making it suitable for a wide range of applications.

One of the primary applications of continuous wire is in the manufacturing of electrical conductors. Continuous copper wire is essential for electrical wiring, providing excellent conductivity and durability. The demand for electricity continues to rise globally, necessitating the production of reliable electrical components that can withstand varying environmental conditions. Continuous wire technology meets this need by ensuring that the wire can be produced in long lengths without compromising quality.

continuous wire

Continuous wire is also integral in the construction industry, where it is often used in reinforcing concrete structures. This type of wire, known as welded wire reinforcement, is produced in large rolls and is easy to handle on construction sites. Its consistent strength and flexibility make it an ideal choice for enhancing the tensile strength of concrete, reducing the risk of cracks and structural failures.

In the realm of automation and robotics, continuous wire finds its place in the creation of seamless, robust components for machines. The automotive and aerospace industries benefit from the high tensile strength of continuous wire, which is vital for manufacturing parts that require high durability and reliability under stress.

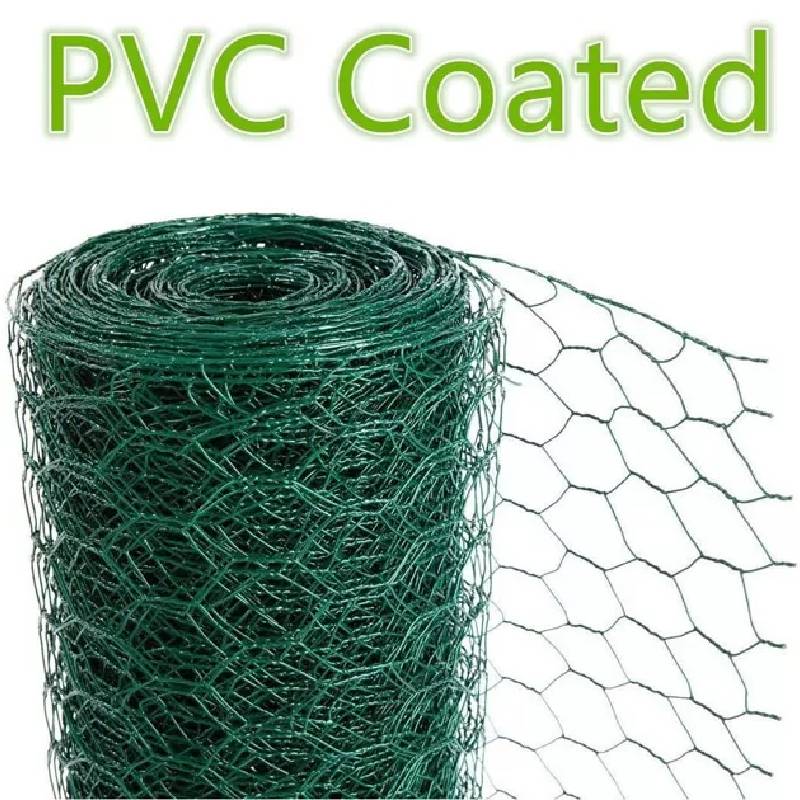

Moreover, the advancements in technology have led to the development of various coating techniques that protect continuous wire from corrosion and wear. This further enhances its longevity and performance, especially in harsh environments.

In conclusion, continuous wire technology has made significant strides in manufacturing processes and applications across multiple industries. Its efficiency, coupled with the ability to produce high-quality, durable wire, makes it an invaluable asset in today's fast-paced industrial landscape. As technological advancements continue to evolve, the potential for continuous wire applications will undoubtedly expand, paving the way for innovative solutions in various fields.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025