- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Mar . 05, 2025 01:09

Back to list

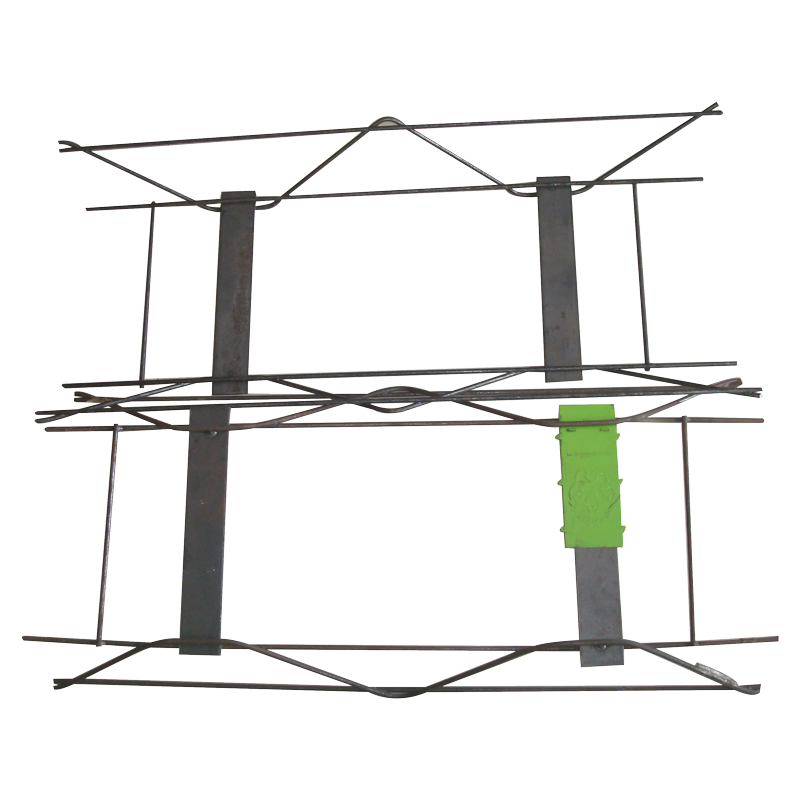

concrete wire mesh size chart

Concrete wire mesh plays a pivotal role in the construction industry, providing essential support and stability to structures. Selecting the right wire mesh size can significantly influence the durability and strength of your concrete projects. This comprehensive guide aims to shed light on the various sizes available, offering insights from experienced professionals and authoritative voices in the industry.

For infrastructure projects such as bridges or industrial floors, even larger sizes are imperative. An 8 mm or even a 10 mm diameter wire with a 200 mm x 200 mm grid offers robust reinforcement. These configurations are crucial when maximum strength and minimal flex are required, often recommended by engineers and construction specialists who underscore the importance of reliability in high-stakes environments. Selecting the appropriate wire mesh size is not solely about the dimensions; factors like material type and coating also play a significant role. Galvanized steel wire mesh, for instance, offers added corrosion resistance, making it suitable for projects exposed to moisture or chemical elements. Experts in material science often advocate for galvanized options in humid climates or coastal areas, due to their long-term performance benefits. Experience in working with concrete wire mesh reveals that proper installation is as vital as selecting the right size. Engineers stress the importance of ensuring the mesh is adequately supported and positioned within the concrete to maximize its reinforcing benefits. This involves careful placement and sometimes even the use of spacers to maintain the mesh in the correct plane, ensuring even weight distribution. Trustworthiness in choosing wire mesh also comes from opting for reputable manufacturers who adhere to industry standards. A product coming from an ISO-certified factory is more likely to meet the required specifications, offering peace of mind to engineers and clients alike. Checking for certifications and customer reviews can provide additional assurance regarding product quality. In conclusion, selecting the right concrete wire mesh size is a nuanced decision that impacts the integrity and safety of construction projects. By considering factors such as wire diameter, grid spacing, material, and manufacturer reputation, you can make informed choices. This not only ensures the longevity and stability of your structure but also builds trust with clients and stakeholders by delivering outcomes that meet or exceed expectations. The expertise of industry professionals and authoritative voices offers invaluable guidance, helping navigate the complexities of wire mesh selection for optimal project success.

For infrastructure projects such as bridges or industrial floors, even larger sizes are imperative. An 8 mm or even a 10 mm diameter wire with a 200 mm x 200 mm grid offers robust reinforcement. These configurations are crucial when maximum strength and minimal flex are required, often recommended by engineers and construction specialists who underscore the importance of reliability in high-stakes environments. Selecting the appropriate wire mesh size is not solely about the dimensions; factors like material type and coating also play a significant role. Galvanized steel wire mesh, for instance, offers added corrosion resistance, making it suitable for projects exposed to moisture or chemical elements. Experts in material science often advocate for galvanized options in humid climates or coastal areas, due to their long-term performance benefits. Experience in working with concrete wire mesh reveals that proper installation is as vital as selecting the right size. Engineers stress the importance of ensuring the mesh is adequately supported and positioned within the concrete to maximize its reinforcing benefits. This involves careful placement and sometimes even the use of spacers to maintain the mesh in the correct plane, ensuring even weight distribution. Trustworthiness in choosing wire mesh also comes from opting for reputable manufacturers who adhere to industry standards. A product coming from an ISO-certified factory is more likely to meet the required specifications, offering peace of mind to engineers and clients alike. Checking for certifications and customer reviews can provide additional assurance regarding product quality. In conclusion, selecting the right concrete wire mesh size is a nuanced decision that impacts the integrity and safety of construction projects. By considering factors such as wire diameter, grid spacing, material, and manufacturer reputation, you can make informed choices. This not only ensures the longevity and stability of your structure but also builds trust with clients and stakeholders by delivering outcomes that meet or exceed expectations. The expertise of industry professionals and authoritative voices offers invaluable guidance, helping navigate the complexities of wire mesh selection for optimal project success.

share:

Latest news

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025