- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

concrete mesh types

Understanding Concrete Mesh Types A Comprehensive Guide

Concrete mesh, a pivotal element in construction, plays a crucial role in enhancing the strength and durability of concrete structures. With various types of concrete mesh available, understanding the distinctions and appropriate applications is essential for architects, engineers, and contractors alike. This article delves into the different types of concrete mesh, their characteristics, and where they are typically used.

What is Concrete Mesh?

Concrete mesh, often referred to as reinforcement mesh, is a grid-like structure made from steel wires that is embedded within concrete to provide tensile strength. The primary purpose of using mesh in concrete is to reduce cracking caused by shrinkage, improve load-bearing capacity, and enhance overall stability.

Types of Concrete Mesh

1. Welded Wire Mesh

Welded wire mesh is one of the most common types of concrete reinforcement. It is constructed from longitudinal and cross wires that are welded at their intersections. The mesh is available in various spacing configurations and wire diameters, making it adaptable for different applications. Welded wire mesh is particularly effective in slabs, pavements, and precast concrete products, providing uniform strength across large areas.

Fiberglass reinforced mesh offers a lightweight alternative to traditional steel mesh. Made from high-strength fiberglass strands, this type of mesh is resistant to corrosion and chemical reactions, making it ideal for use in environments where moisture and chemicals are prevalent. However, it is vital to ensure that fiberglass mesh is adequately protected when used in concrete applications to prevent exposure to UV light, which can degrade its tensile properties.

concrete mesh types

3. Steel Reinforcing Bars (Rebar)

While technically not a mesh, rebar is often used in conjunction with concrete mesh systems. Rebar consists of steel rods that are manufactured in various diameters and lengths. When used together with mesh, rebar significantly increases the tensile strength of the concrete, making it suitable for high-load applications such as bridges, highways, and commercial buildings.

4. Polypropylene Fiber Mesh

Polypropylene fiber mesh is a modern alternative to traditional wire mesh. It comprises fine polypropylene fibers that are distributed throughout the concrete mix. This type of reinforcement is effective in controlling shrinkage cracks, particularly in slabs and pavements. Polypropylene fiber mesh is often used in residential projects due to its ease of use and cost-effectiveness.

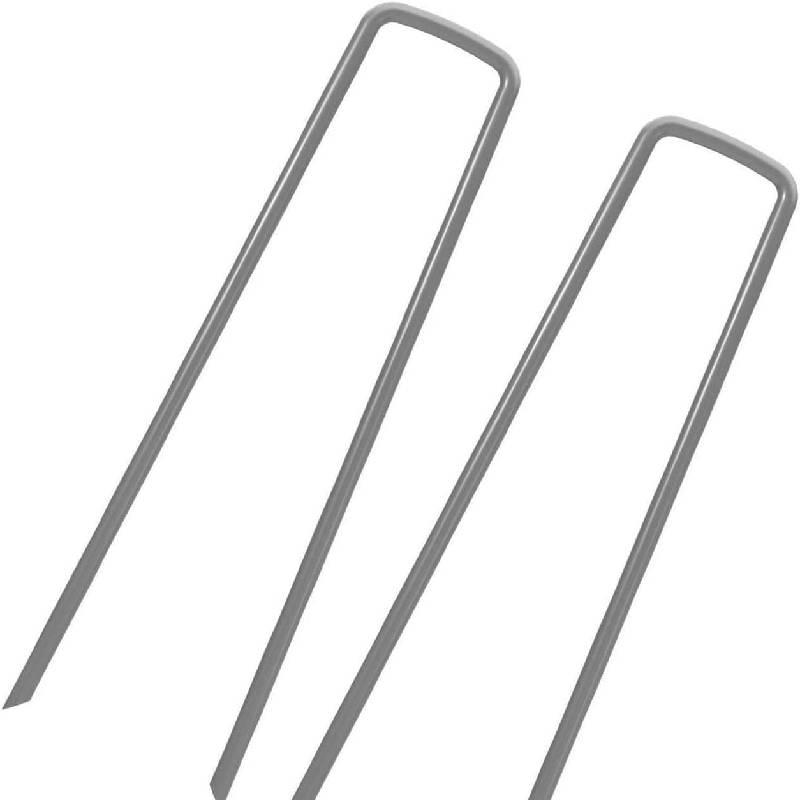

5. Galvanized Mesh

Galvanized mesh is coated with zinc, which provides excellent corrosion resistance. It is ideal for use in areas that are exposed to moisture and harsh environments, such as marine and underground applications. The galvanized layer protects the steel from rusting, ensuring the longevity of the reinforcement.

Conclusion

Selecting the appropriate type of concrete mesh is critical for the success of any construction project. Each type of mesh comes with its own set of advantages and is suited for specific applications. Welded wire mesh is widely used in general construction, fiberglass mesh caters to chemically aggressive environments, and rebar complements mesh for additional strength. Understanding these different types will help construction professionals make informed decisions, ultimately leading to safer and more durable structures. As the industry evolves, new materials and technologies continue to emerge, promising even more innovative solutions for reinforcing concrete.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025