- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding the Expenses Involved in Concrete Mesh Construction Materials

Understanding the Costs of Concrete Mesh A Comprehensive Guide

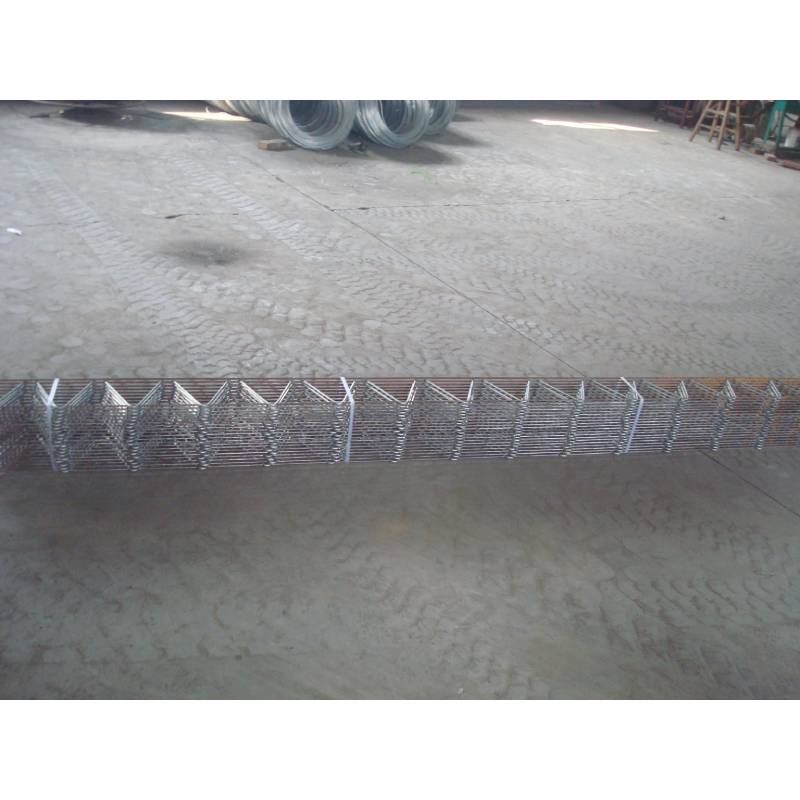

Concrete mesh, commonly known as welded wire reinforcement, plays a vital role in the construction and civil engineering sectors. It provides the necessary structural integrity and durability for concrete slabs, foundations, and various other applications. When embarking on a construction project, it's crucial to understand the costs associated with concrete mesh, as these can significantly affect the overall budget. This article delves into various factors influencing the cost of concrete mesh, different types available, and tips for effectively managing your budget.

Factors Affecting Concrete Mesh Costs

Several elements contribute to the fluctuating costs of concrete mesh. Here are the primary factors to consider

1. Material Type The composition of the mesh directly affects its price. Common materials include steel and fiberglass. Steel mesh generally comes with a lower upfront cost but may be susceptible to corrosion, requiring protective coatings. Fiberglass mesh, while more expensive, is resistant to environmental stresses and offers longevity.

2. Mesh Size and Thickness The dimensions of the mesh are crucial in determining its price. Larger and thicker meshes that can withstand greater loads will naturally cost more. It is essential to evaluate the specific requirements of your project to avoid over- or under-specifying your mesh.

3. Weld Quality The quality of the welding process impacts both the performance and longevity of the mesh. Higher quality welds ensure better structural integrity but usually come at a higher price. Investing in quality can save money in repairs and replacements in the long run.

4. Production Volume The overall cost can also be influenced by the amount of concrete mesh purchased. Bulk buying often provides leverage for negotiating lower prices. Contractors working on large-scale projects can benefit from the economies of scale.

5. Local Market Conditions Prices may vary significantly by region due to local production capabilities, transport costs, and demand. Always compare prices and consider sourcing from local suppliers to minimize transportation costs.

Types of Concrete Mesh

Concrete mesh comes in various forms, each tailored for specific applications

1. Welded Wire Mesh This is the most common type, featuring a grid of wires welded together. It is ideal for floor slabs, walls, and overhead applications due to its versatile nature.

concrete mesh cost

2. Fiberglass Reinforcement Mesh Primarily used in applications where corrosion is a risk, such as coastal constructions, this type offers excellent durability and is lightweight.

3. Expanded Metal Mesh This mesh is produced from a single sheet of metal that is cut and stretched. Its design provides increased strength and is suitable for protective barriers and architectural applications.

Budget Management Tips

To effectively manage your budget while ensuring the best quality concrete mesh, consider the following strategies

1. Conduct a Needs Assessment Clearly define your project requirements to determine what type and grade of mesh you need. Avoid purchasing excessive materials.

2. Get Multiple Quotes Reach out to various suppliers to obtain multiple quotes. This allows you to compare prices and negotiate better deals.

3. Consider Long-Term Value While it may be tempting to opt for the cheapest option, consider the long-term costs associated with maintenance and repairs. Often, investing in higher-quality mesh can be more economical over time.

4. Plan for Installation Factor in installation costs when budgeting for concrete mesh. It is advisable to work with experienced contractors, as improper installation can compromise the structure.

5. Stay Informed About Trends Keeping abreast of market trends can help you anticipate price changes and make informed purchasing decisions.

Conclusion

Understanding the costs associated with concrete mesh is essential for any construction project. By considering the numerous factors that affect pricing, exploring various types, and applying effective budget management strategies, contractors and builders can ensure their projects remain within budget while achieving the desired structural integrity. Ultimately, investing in reliable and high-quality concrete mesh not only enhances safety and performance but also contributes to the overall success of the project.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025