- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

20mm Compression Spring Specifications and Applications for Industrial Use

Understanding Compression Springs A Focus on 20mm Models

Compression springs are one of the most commonly utilized types of springs in various industries, serving critical roles in mechanical systems and devices. Among the myriad sizes and specifications available, the 20mm compression spring stands out for its versatility and functionality. In this article, we will explore the fundamental characteristics of compression springs, the importance of size like the 20mm model, and their applications in everyday life.

What is a Compression Spring?

A compression spring is a mechanical component designed to resist axial loads. These springs are wound in a helical shape and are made from high-carbon steel or stainless steel, which provides the necessary strength and elasticity. When a force is applied to compress the spring, it stores potential energy, which is released when the force is removed. The design of the compression spring allows it to return to its original length after being compressed, making it essential for devices that require repeated cycles of operation.

The Significance of a 20mm Compression Spring

The term 20mm compression spring refers specifically to the diameter of the spring, which is a crucial parameter that influences its performance in different applications. A 20mm spring offers a balanced combination of size and compressibility, making it adaptable to various environments. The choice of a 20mm compression spring often reflects the requirement for both strength and space efficiency; it fits seamlessly into compact assemblies while still providing adequate resistance and durability.

Key Characteristics of Compression Springs

1. Material Most compression springs are made from metals like carbon steel, stainless steel, or alloys, which provide both strength and flexibility. 2. Spring Rate This is a measure of the stiffness of the spring and is defined as the amount of force required to compress the spring by a unit distance. A 20mm compression spring can be engineered for different spring rates depending on the required load application.

3. Coil Diameter and Wire Diameter The coil diameter and wire diameter play significant roles in determining the overall performance and load-bearing capacity of the spring. For example, a 20mm spring may have various wire thicknesses, affecting its strength and flexibility.

compression spring 20mm

4. Free Length This refers to the length of the spring when it is not under any load. The free length must be considered carefully to ensure that the spring fits appropriately within the assembly it is designed for.

Applications of 20mm Compression Springs

Due to their adaptable nature, 20mm compression springs are prevalent across a broad range of industries. Some of the most common applications include

- Automotive They are used in suspension systems, engine components, and various mechanical assemblies to absorb shocks and manage stress. - Aerospace Compression springs assist in numerous systems, including landing gear mechanisms, where reliability and strength are critical.

- Electronics In devices like keyboards, remote controls, and other handheld devices, the 20mm compression spring is often employed for tactile feedback mechanisms.

- Home Appliances Many household items, such as mattresses, chairs, and various kitchen gadgets, utilize compression springs to enhance functionality and comfort.

Conclusion

The 20mm compression spring is an exemplary representation of how a simple mechanical component can significantly impact various industries and everyday life. With its ability to absorb forces and return to shape, it serves fundamental roles in many machines and devices we use daily. Understanding the properties and applications of compression springs can help designers, engineers, and manufacturers choose the right specifications for their needs. As technology continues to evolve, the design and materials of such springs will likely advance, leading to even more innovative applications and improved performance in the years to come.

share:

-

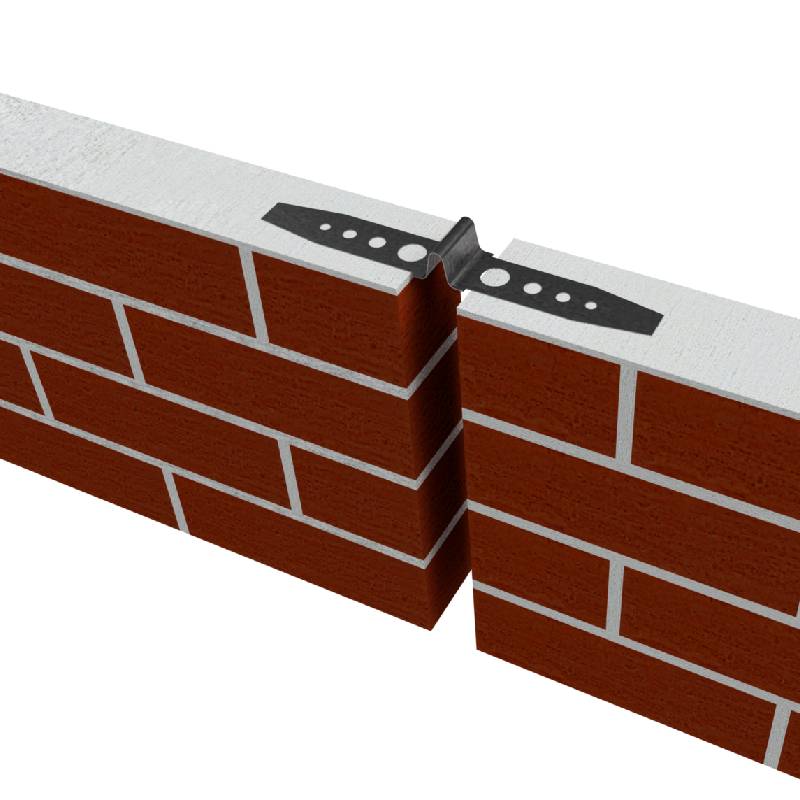

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025