- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

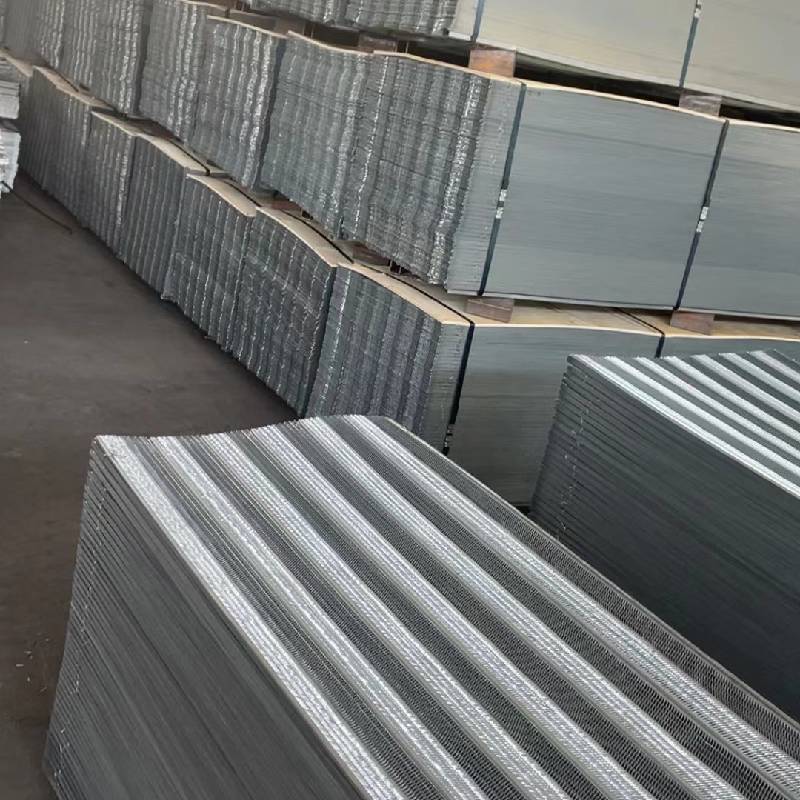

compression flat wire springs

Understanding Compression Flat Wire Springs Applications and Advantages

Compression flat wire springs are vital components in various industrial and commercial applications due to their unique design, efficiency, and effectiveness in providing support and resistance. These springs are made from flat wire, which allows them to handle higher loads and provide uniform force distribution. This article delves into the characteristics, benefits, and applications of compression flat wire springs.

Design and Construction

Compression flat wire springs are crafted from high-quality flat wire materials, which offer enhanced strength and flexibility. Unlike traditional round wire springs, flat wire springs have a larger surface area, which allows for better load distribution. This unique design minimizes stress concentrations and enhances durability, making them ideal for applications that require high fatigue resistance. The manufacturing process involves precise shaping and heat treatment, ensuring that these springs can endure significant compression without losing their performance.

Advantages of Compression Flat Wire Springs

1. Space Efficiency Compression flat wire springs are often more compact than their round counterparts. Their flat design allows for a lower profile, which is particularly beneficial in applications where space is limited. This compactness helps manufacturers optimize the design of their products without compromising on performance.

2. Enhanced Load Capacity Because of their design, flat wire springs can handle higher loads while maintaining stability. This capability is crucial in many engineering applications where longevity and reliability are necessary.

3. Improved Force Distribution The larger surface area of flat wire springs enables even distribution of forces across the spring. This characteristic minimizes wear and tear, extending the lifespan of both the spring and the components it is connected to.

4. Customization Compression flat wire springs can be easily customized to fit specific dimensions and performance requirements. Manufacturers can adjust variables such as thickness, width, and coil pitch to create a spring that perfectly meets the application’s needs.

compression flat wire springs

Applications

Compression flat wire springs are used in a wide array of industries, showcasing their versatility.

1. Automotive Industry They are commonly found in suspension systems, seat mechanisms, and various components of vehicles, where they help absorb shocks and support moving parts.

2. Aerospace The aerospace sector utilizes compression flat wire springs in various applications, ranging from landing gear systems to control surfaces, to ensure reliable performance under extreme conditions.

3. Electronics In electronic devices, flat wire springs are employed in configurations such as battery contacts and switch mechanisms, where their compactness and load capacity enhance functionality.

4. Medical Devices These springs are used in a variety of medical equipment, including surgical instruments and patient monitoring devices, where precision and reliability are paramount.

Conclusion

Compression flat wire springs are essential in modern engineering, offering distinct advantages over traditional spring designs. Their unique characteristics enable various applications across multiple industries, making them a preferred choice for engineers and designers. As technology advances and the demand for more sophisticated designs increases, compression flat wire springs will likely play an even more significant role in the future of engineering solutions. Understanding their benefits and applications is crucial for professionals looking to leverage these components in their projects.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025