- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

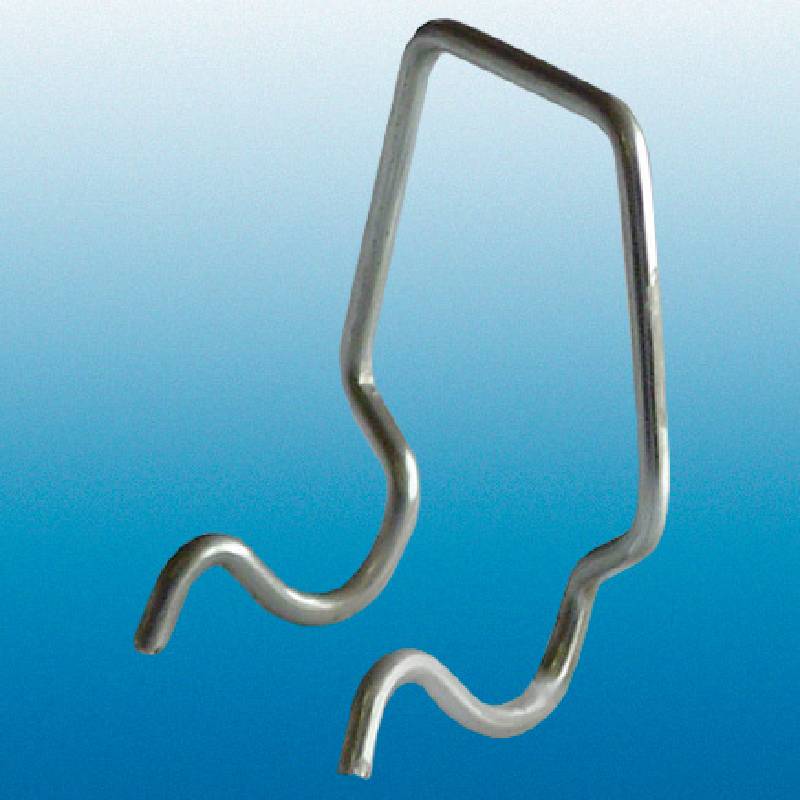

compression extension spring

Understanding Compression Extension Springs

Compression extension springs are vital components used in various mechanical systems, providing essential support and flexibility. These springs are designed to store mechanical energy when compressed and release it when extended, making them integral to numerous applications ranging from automotive to industrial machinery. This article delves into the characteristics, applications, and benefits of compression extension springs, further highlighting their significance in modern engineering.

What are Compression Extension Springs?

Compression extension springs are a specific type of spring that operates under compressive forces. Unlike tension springs, which are designed to absorb tension (pulling forces), compression extension springs work by resisting compressive loads. These springs are characterized by their coiled shape, which allows them to accommodate various loads and provide resilience in dynamic applications.

The design of compression extension springs varies based on their intended use, with materials typically including steel, stainless steel, and other alloys. The choice of material directly influences the spring's strength, flexibility, and overall durability. Furthermore, the manufacturing process for these springs often involves precision methods to ensure uniform coil spacing and resilience under repeated loading conditions.

Applications of Compression Extension Springs

Compression extension springs are widely employed in numerous industries due to their versatility. Here are some common applications

1. Automotive Industry In vehicles, these springs are used in suspension systems, helping to cushion rides and absorb shocks. They also play a role in various mechanisms, such as throttle controls and clutch systems.

2. Manufacturing Equipment These springs are found in machinery that requires precise movements or the storing of potential energy. They assist in processes that involve repetitive motions, where reliable performance is critical for efficiency and safety.

3. Consumer Products Compression extension springs are commonly used in everyday items, from office equipment like printers and photocopiers to children's toys that require mechanical movement. Their presence in these products underscores their importance in enhancing functionality.

compression extension spring

4. Medical Devices In the medical field, these springs can be found in devices such as surgical instruments or patient monitoring equipment, where they contribute to the required precision and responsiveness.

Benefits of Compression Extension Springs

The use of compression extension springs comes with several advantages

- Durability Constructed from high-quality materials, these springs are designed to withstand wear and tear, ensuring a long lifespan under various operational conditions.

- Compact Design Their coiled structure allows them to occupy less space while providing significant force output, making them ideal for applications where space is limited.

- Versatility Compression extension springs can be tailored to meet specific operational requirements, including size, load capacity, and spring rate, making them highly customizable for a range of applications.

- Cost-Effectiveness With their durability and longevity, compression extension springs often represent a cost-effective solution for manufacturers and consumers, reducing the need for frequent replacements.

Conclusion

Compression extension springs are indispensable elements in mechanical design and engineering. Their ability to absorb and release energy under load makes them essential in various applications across multiple industries. As technology continues to advance, the evolution of materials and manufacturing techniques will likely enhance the performance and applications of these springs even further. Whether in automobiles, consumer goods, or complex machinery, compression extension springs will remain a cornerstone of modern engineering, providing the support and flexibility necessary to drive innovation and efficiency. Understanding their functions and applications will enable engineers and designers to better integrate these critical components into new designs, ensuring that they continue to meet the demands of the future.

By appreciating the role and functionality of compression extension springs, industry professionals can leverage their strengths to improve product performance and reliability, ultimately enhancing user experiences across all sectors.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025