- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding the Functionality and Applications of Compression and Extension Springs

Understanding Compression and Extension Springs

In the intricate world of mechanical engineering, springs play a crucial role in various applications, providing the necessary force and flexibility. Two of the most commonly used types of springs are compression springs and extension springs. Each of these springs serves distinct purposes and operates under different principles, yet both are vital in ensuring smooth operation across numerous devices and systems.

Compression Springs

Compression springs are designed to absorb energy and maintain a force between their ends. These springs are typically made from metal and are characterized by their helical shape. When a compression spring is compressed, the coils are pushed closer together, storing potential energy. Once the force is removed, the spring returns to its original state, releasing the stored energy.

The applications of compression springs are vast. They are commonly found in automotive components, such as shock absorbers, where they help to cushion impacts, and in machinery to offer resistance against pressure. Compression springs also play a crucial role in everyday items, including pens and mattresses, providing the necessary resilience and comfort.

A key factor in the design of compression springs is the spring constant, which determines how much force is required to compress the spring by a certain distance. This constant can vary based on the material used, the number of coils, and the diameter of the spring. Engineers often conduct rigorous calculations to ensure that the compression spring meets the specific demands of its application.

Extension Springs

Contrary to compression springs, extension springs are designed to operate under tension rather than compression. These springs are also typically made from metal and are characterized by their tightly coiled construction. When an extension spring is stretched, it creates a pulling force that seeks to return to its original length. The energy stored in an extension spring is released as it returns to its resting state.

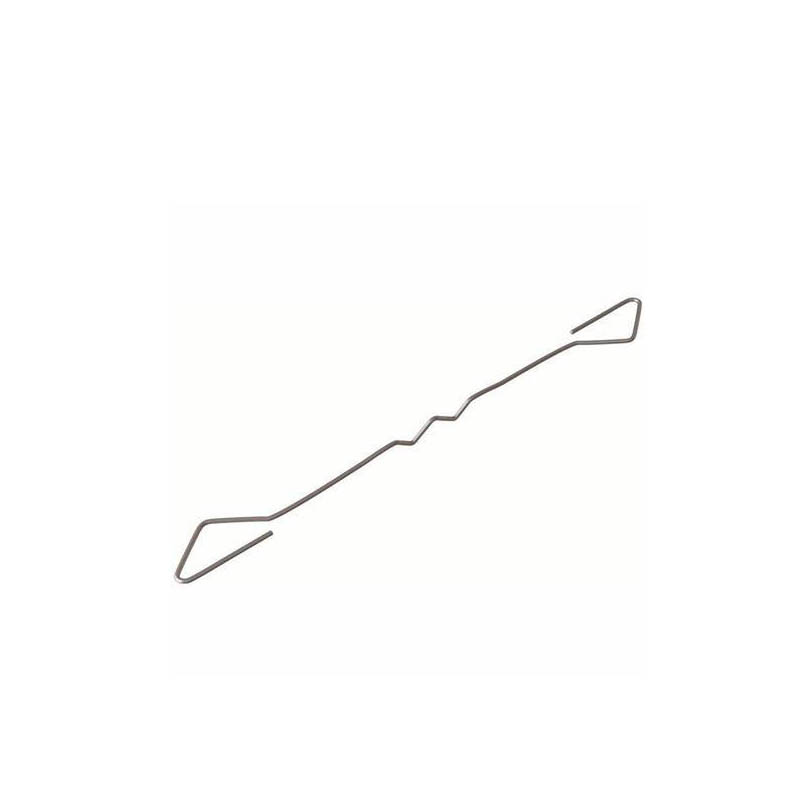

compression and extension springs

Extension springs find their application in various mechanisms, such as in doors and hatches that require assistance in opening and closing. They are also commonly found in trolling motors, where they help maintain tension in cables, and in agricultural equipment, providing the necessary force to assist in the functioning of complex machinery.

The design of extension springs must account for factors such as the load they will sustain and the elongation required

. Unlike compression springs, the spring constant for extension springs is calculated differently, taking into account their different operational dynamics.Applications and Importance

Both compression and extension springs play critical roles across many industries, including automotive, aerospace, manufacturing, and consumer products. Their ability to absorb shock and maintain force makes them indispensable in machinery relying on repetitive motion or the need for dynamic energy management.

Furthermore, the material selection for both types of springs is crucial. Common materials include stainless steel, music wire, and oil-tempered wire, each chosen for its specific properties such as elasticity, corrosion resistance, and strength. Advances in materials science have led to the development of innovative composite springs, which offer enhanced performance and durability.

Conclusion

In conclusion, compression and extension springs are fundamental components that contribute significantly to the functionality of countless mechanical systems. By understanding their design, operation, and applications, engineers can innovate and improve efficiency in various industries. As technology evolves, the ongoing refinement of spring manufacturing and materials will continue to enhance the performance and reliability of these essential devices. Whether it’s ensuring the smooth operation of a vehicle or providing the necessary support in everyday objects, springs remain a pivotal element in the realm of engineering.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025