- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

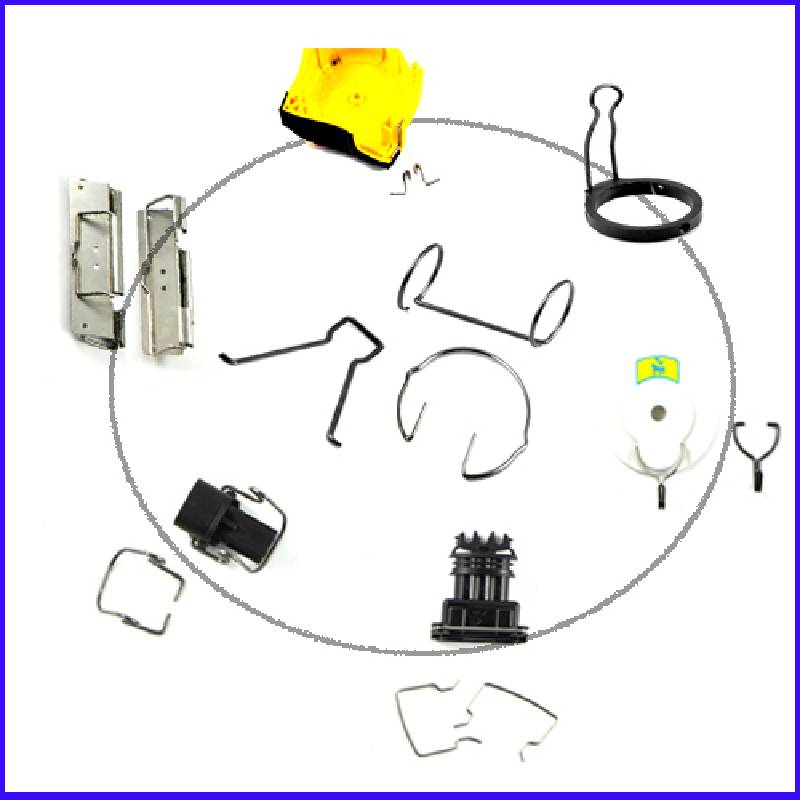

Quality Compression Springs for Sale - Durable & Custom Solutions

Compression Springs for Sale Finding the Right Fit for Your Needs

Compression springs are one of the most commonly used types of springs in various applications. These helical springs are designed to resist compressive forces and are widely utilized in industries such as automotive, aerospace, electronics, and consumer goods. With the growing demand for compression springs, many suppliers are offering a wide range of options for sale. This article will explore the characteristics of compression springs, their applications, and what to consider when purchasing them.

Characteristics of Compression Springs

Compression springs are typically made from high-carbon steel, stainless steel, or other materials that provide the necessary elasticity and strength. They come in different configurations, including round, square, and rectangular wire shapes, allowing for versatility in design. The key characteristics of compression springs include wire diameter, coil diameter, number of active coils, and spring rate. These parameters determine how much force the spring can withstand and how much it will compress under load.

Applications of Compression Springs

The applications of compression springs are vast and diverse. In the automotive industry, they are used in suspension systems, engine components, and various mechanical systems, playing a crucial role in enhancing performance and safety. In consumer products, compression springs can be found in items like pens, mattresses, and appliances, providing functionality and comfort.

Furthermore, in industrial settings, compression springs are vital for machinery and equipment, including valves, clutches, and dampers

. The versatility of compression springs allows them to be tailored to specific requirements, making them an indispensable component in modern manufacturing and engineering.compression springs for sale

Considerations When Purchasing Compression Springs

When searching for compression springs for sale, several factors should be considered to ensure you select the right product for your needs. First, identify the specific requirements of your application, including load capacity, size, and environmental conditions. Different applications may require springs that can withstand high temperatures, corrosion, or fatigue.

Next, evaluate the quality of the springs. It's essential to choose products from reputable manufacturers that adhere to industry standards, ensuring durability and performance. Additionally, consider the customization options available, as some applications may necessitate bespoke configurations tailored to specific dimensions and load requirements.

Lastly, pricing and lead time are crucial factors. While it may be tempting to go for the cheapest option, investing in quality can save money in the long run by reducing the need for replacements. Additionally, assess the supplier’s ability to meet your delivery timelines, especially if you are operating on a tight schedule.

Conclusion

Compression springs are fundamental components in a myriad of applications, making it essential to choose the right spring for your requirements. With a plethora of options available for sale, understanding the characteristics, applications, and purchasing considerations will help you make an informed decision. Whether you are in manufacturing, automotive, or any other industry, the right compression spring can significantly enhance the efficiency and functionality of your products.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025