- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

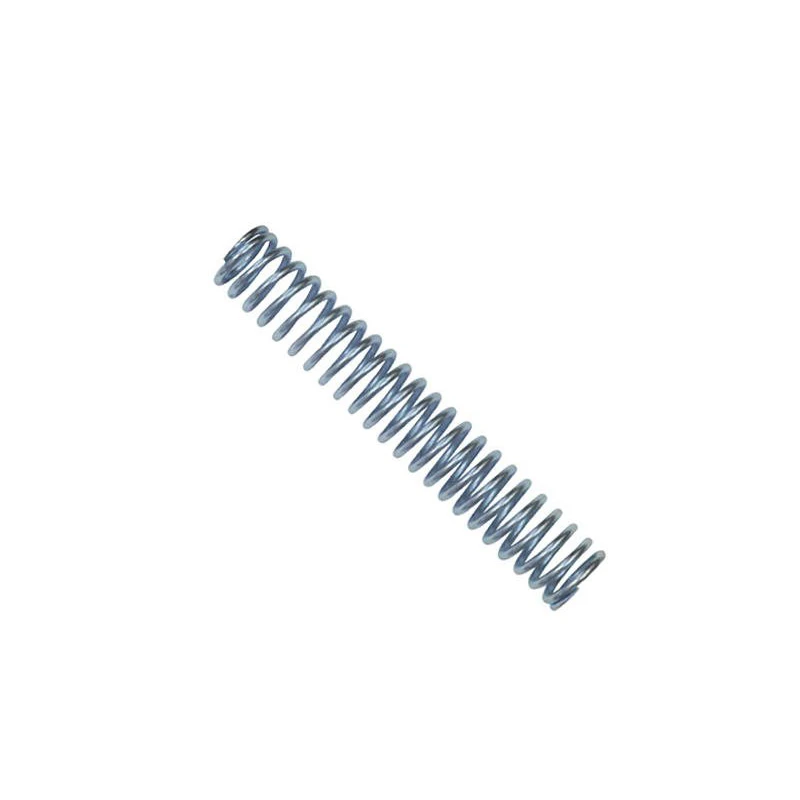

compressible spring

Understanding Compressible Springs Mechanisms and Applications

Springs are ubiquitous components in mechanical design, playing crucial roles in a variety of applications. Among the various types of springs, compressible springs stand out due to their unique characteristics and functional advantages. This article delves into the mechanics, types, and applications of compressible springs, providing insight into their significance in engineering and everyday life.

What are Compressible Springs?

Compressible springs, commonly known as compression springs, are designed to resist compressive forces. These springs have coils that are close together when at rest, and as force is applied, the coils compress, allowing the spring to store potential energy. The core principle governing their operation is Hooke's Law, which states that the force exerted by a spring is directly proportional to the distance it is compressed. Mathematically, this can be expressed as F = kx, where F is the force applied to the spring, k is the spring constant (a measure of stiffness), and x is the displacement from the spring's resting position.

Types of Compressible Springs

Compression springs come in various shapes and sizes, each tailored for specific applications. The most common types include

1. Cylindrical Compression Springs These are perhaps the most recognizable form of compressible springs. They feature a helical coil structure, and are often used in automotive and machinery contexts due to their robustness.

2. Conical Compression Springs Shaped like a cone, these springs have a tapered design that allows them to compress more smoothly, which can provide a variable resistance. This makes them suitable for applications requiring gradual force.

3. X-Shape Compression Springs Characterized by an ‘X’ shaped cross-section, these springs combine several benefits, including improved stability and enhanced load distribution.

4. Belleville Washers Often categorized under compression springs, these disc-shaped springs are used to exert force when compressed. They are commonly found in applications where space is limited but strong resistance is needed, such as in automotive suspensions.

compressible spring

Applications of Compressible Springs

The versatility of compressible springs means they find applications in numerous fields

1. Automotive Industry Compression springs are integral to vehicle suspension systems. They absorb shocks from the road, contributing to a smoother ride while also maintaining control and stability.

2. Consumer Electronics In devices like keyboards, remote controls, and even smartphones, compression springs are critical for buttons and switches, providing tactile feedback and ensuring proper function.

3. Industrial Equipment Many complex machines rely on compression springs to maintain tension and stability. They are used in mechanisms ranging from conveyor belts to hydraulic systems.

4. Medical Devices Compression springs are used in medical equipment such as hospital beds and mechanical assist devices. Their reliable force generation can be crucial for patient comfort and proper functioning.

5. Aerospace In the aerospace sector, compression springs play vital roles in systems that require precise and repeatable motion, such as landing gear and control surfaces.

Conclusion

Compressible springs are fundamental components that significantly enhance the functionality and efficiency of various mechanical systems. Their ability to absorb shock, store energy, and provide consistent resistance makes them invaluable in countless applications. As technology continues to evolve, the design and material of compression springs are also advancing, allowing for greater strength, durability, and versatility.

In an increasingly mechanized world, understanding the mechanisms and applications of compressible springs can unlock potential improvements in design and efficiency in multiple domains, ensuring they remain a key focus for engineers and designers alike. As research continues into new materials and designs, the future of compression springs promises even greater innovations, continuing to support the complex machinery and devices that enhance our daily lives. Whether you encounter them in your vehicle, household gadgets, or industrial equipment, compression springs are an essential part of the mechanical landscape.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025