- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

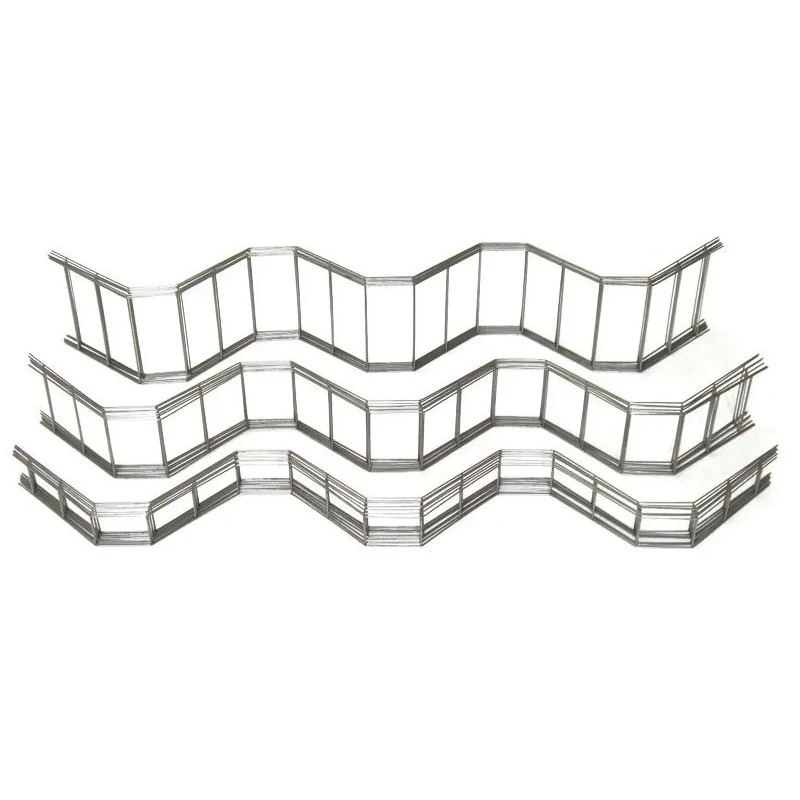

composite coil springs

The Evolution and Benefits of Composite Coil Springs

In the realm of engineering and design, materials play a pivotal role in determining the efficiency and effectiveness of mechanical systems. Among the various innovations, composite coil springs have emerged as a significant advancement, delivering superior performance in a range of applications. These springs are not just a replacement for traditional metal springs; they represent a shift in how engineers can approach design challenges.

Understanding Composite Coil Springs

Composite coil springs are manufactured from a combination of materials, typically featuring a composite polymer matrix reinforced with fibers such as carbon, glass, or aramid. This unique structure results in a lightweight yet exceptionally strong spring that can outperform conventional metal springs in multiple ways. The alternative choice of materials allows for greater design flexibility, enabling engineers to tailor spring characteristics according to specific application needs.

One of the most notable features of composite coil springs is their ability to maintain high strength-to-weight ratios. This characteristic is increasingly important in industries where weight reduction is critical for performance, such as aerospace, automotive, and sports equipment. By substituting metal with composite materials, manufacturers can produce lighter components without compromising on strength or durability.

Advantages of Composite Coil Springs

1. Weight Reduction The most apparent benefit of composite coil springs is their significantly lower weight compared to traditional steel springs. This reduction directly translates into enhanced fuel efficiency in vehicles and improved performance in aircraft, where every ounce counts.

2. Corrosion Resistance Composite materials inherently resist corrosion and environmental degradation, making composite coil springs ideal for applications exposed to harsh conditions. Not only does this extend the lifespan of the components, but it also reduces maintenance costs and downtime.

3. Design Flexibility Composite materials can be molded into various shapes and configurations, allowing for innovative designs that may not be feasible with metal springs. This flexibility opens new avenues for custom solutions tailored to specific engineering challenges.

composite coil springs

4. Fatigue Resistance Composite materials exhibit excellent fatigue resistance, meaning they can endure longer operational cycles without succumbing to wear and tear. This durability is especially advantageous in applications involving repetitive motion.

5. Damping Properties Composite coil springs can be designed to provide superior damping characteristics, helping to absorb shock and vibrations effectively. This feature improves the ride quality in vehicles and reduces stress on components, enhancing overall reliability.

Applications of Composite Coil Springs

The applications of composite coil springs are vast and varied. In the automotive industry, they are increasingly used in suspension systems where weight reduction and performance are critical. Racing vehicles, for example, benefit from the enhanced control and reduced body roll provided by composite springs.

In the aerospace sector, lightweight components are essential for maximizing payload capacity and fuel efficiency. Composite coil springs are employed in landing gear and control surfaces, contributing to the overall effectiveness of aircraft design.

Furthermore, their use in the sporting goods industry is gaining traction. From bicycles to high-performance equipment, composite coil springs offer athletes a competitive edge through improved functionality and weight management.

Conclusion

Composite coil springs represent an exciting frontier in engineering and materials technology. Their unique properties offer vast advantages over traditional metal springs, making them an attractive choice across multiple industries. As technology continues to advance, it is likely that we will see even broader adoption of composite materials, reshaping the landscape of mechanical design and enhancing performance in ways previously thought impossible. By leveraging the strengths of composite coil springs, engineers can explore innovative solutions that push the boundaries of what is achievable in modern design.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025