- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

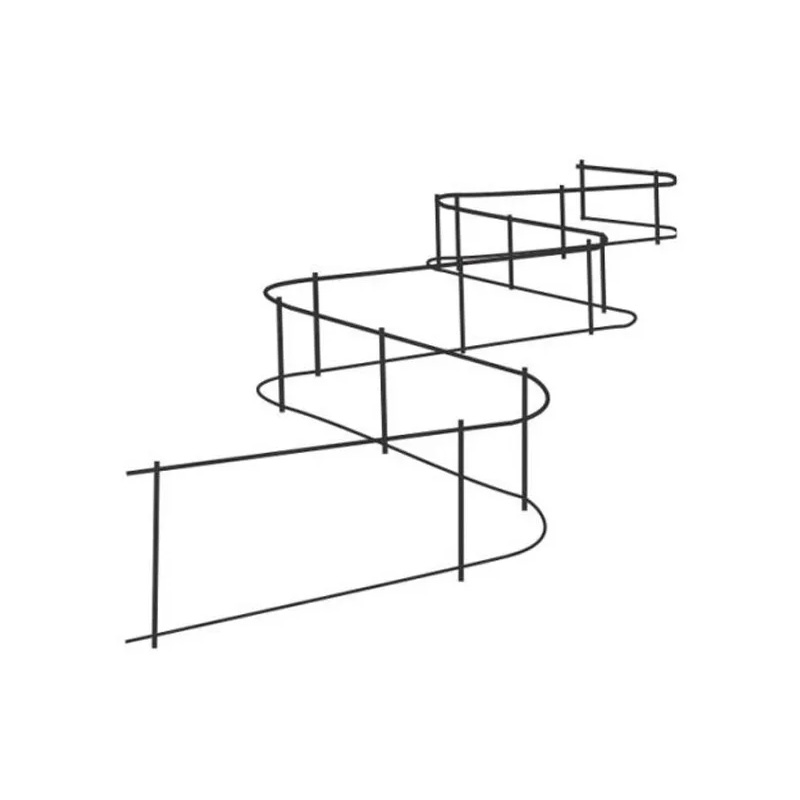

coil compression springs

Understanding Coil Compression Springs Design, Functionality, and Applications

Coil compression springs are vital components utilized in various industries, from automotive to consumer electronics. Their core function is to store and release energy, providing necessary force and support in mechanical systems. Understanding their construction, functionality, and applications is essential for engineers, designers, and anyone involved in manufacturing processes.

A coil compression spring is typically made from metal wire that is coiled into a helical shape. The material used can vary, with options like stainless steel, carbon steel, and alloy steel being common due to their strength and elasticity. The design involves winding the wire in a way that allows the spring to compress when force is applied, and it returns to its original shape once the force is removed. This ability to revert to its resting state is crucial for the spring's functionality.

The performance of a coil compression spring is influenced by several factors, including its diameter, wire thickness, and the number of active coils. These design elements determine the spring's load capacity, which refers to how much weight it can support before deforming. Engineers often use formulas to calculate the spring constant, a measure of stiffness that helps predict how much a spring will compress under a given load.

coil compression springs

Applications for coil compression springs are vast and diverse. In the automotive industry, these springs are found in suspension systems, providing cushioning and stability. They also play a critical role in manufacturing products like pens, mattress support systems, and machinery components. In consumer electronics, coil compression springs can be found in devices like remote controls and various types of switches where they offer tactile feedback.

Another crucial aspect of coil compression springs is their ability to operate under extreme conditions. Manufacturers design them to endure repetitive cycles of compression and extension, thereby ensuring longevity. Additionally, advancements in materials and manufacturing techniques have led to springs that can withstand higher loads and operate in harsher environments, including exposure to chemicals or high temperatures.

In conclusion, coil compression springs are integral to countless applications across various sectors. Their design, functionality, and ability to provide reliable support make them indispensable in modern engineering. Understanding their properties is key for those involved in product design and manufacturing, as it allows for the creation of more efficient, durable, and effective mechanical systems. As technology advances, the evolution of coil compression springs continues, promising even greater innovations in the years to come.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025