- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding the Applications and Benefits of Coated Iron Wire in Various Industries

The Versatility and Applications of Coated Iron Wire

Coated iron wire has become an essential material across various industries due to its durability, flexibility, and resistance to rust and corrosion. This type of wire is typically made from high-quality iron that is coated with a layer of protective material, such as PVC (polyvinyl chloride) or PE (polyethylene). The coating not only enhances the wire’s performance but also contributes to its aesthetic appeal. This article explores the various types of coated iron wire, their manufacturing process, and their diverse applications.

Types of Coated Iron Wire

Coated iron wires come in several forms, each serving a different purpose based on the needs of the end user. One common type is the PVC-coated iron wire, which is known for its strong corrosion resistance and is often used in outdoor applications. This versatile wire is available in various colors, making it an excellent choice for decorative purposes as well. Another type is the galvanized iron wire, which, although not coated with PVC, is treated with a layer of zinc to provide excellent rust resistance. While galvanized wire is primarily used for fencing and construction, PVC-coated wire can be found in both functional and decorative applications, such as tree support and crafted designs.

Manufacturing Process

The manufacturing of coated iron wire involves multiple steps to ensure both strength and quality. Initially, high-quality steel rods are drawn into wire of desired thickness. This wire is then cleaned and prepped for coating. In the case of PVC-coated wire, the wire is fed through a coating machine where it receives its layer of PVC. This process typically involves heating the wire to allow for better adhesion of the coating. After coating, the wire is cooled, cut to specific lengths, and spooled for delivery.

Quality control is a crucial part of the manufacturing process. During production, the wire undergoes several tests to assess its strength, flexibility, and coating adhesion. The final product must meet industry standards before it can be distributed.

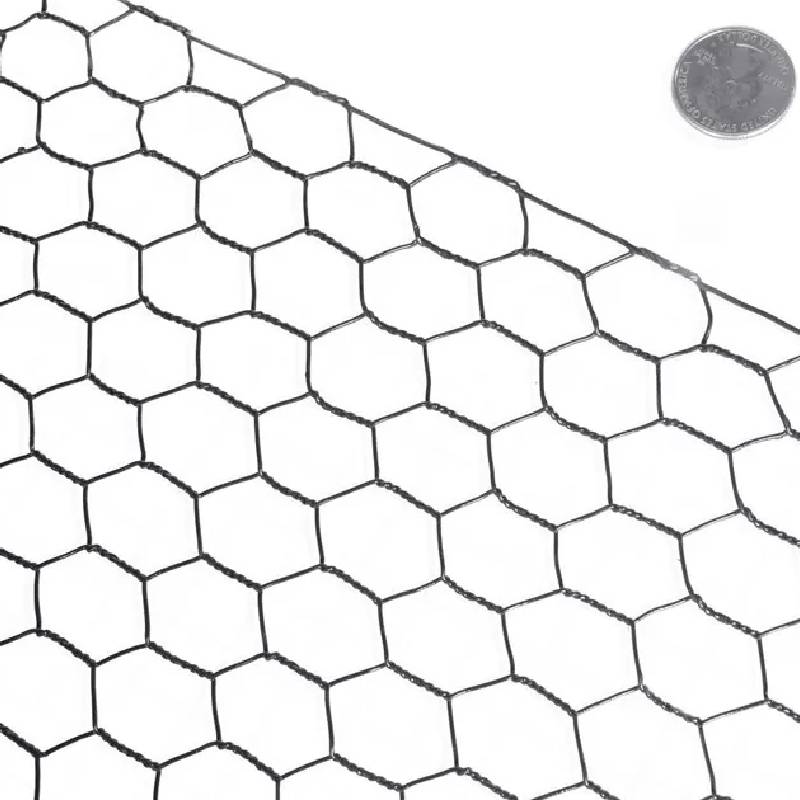

coated iron wire

Applications of Coated Iron Wire

The applications of coated iron wire are virtually unlimited, reflecting its adaptability across various sectors. In the construction and fencing industries, coated iron wire is used for reinforcing concrete, building fences, and securing construction sites. Its durability and resistance to the elements ensure that structures remain safe and intact over time.

In agriculture, coated iron wire is a favorite among farmers for its utility in fencing fields, supporting garden structures, and as trellises for climbing plants. The aesthetic advantage of PVC coating allows the wire to blend seamlessly into natural surroundings while providing functional support.

Coated iron wire also finds its way into the craft and decorative industries. Artisans use it to create intricate designs, sculptures, and garden decorations. The variety of colors available allows artists to choose wire that complements their creations, thus enhancing visual appeal.

The automotive industry also utilizes coated iron wire for various components where strength and resistance to environmental factors are essential. From battery cables to structural components, coated iron wire is a dependable choice.

Conclusion

Coated iron wire stands out as a multifaceted material that caters to a wide range of industries, including construction, agriculture, crafts, and automotive. Its combination of strength, flexibility, and resistance to corrosion makes it an ideal choice for both functional and aesthetic applications. As technology advances, the manufacturing processes and applications for coated iron wire will likely evolve, further establishing its importance in modern industry. Whether one is building a sturdy fence, crafting a beautiful sculpture, or manufacturing critical car components, coated iron wire proves to be a reliable and versatile solution.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025