- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 16, 2025 00:00

Back to list

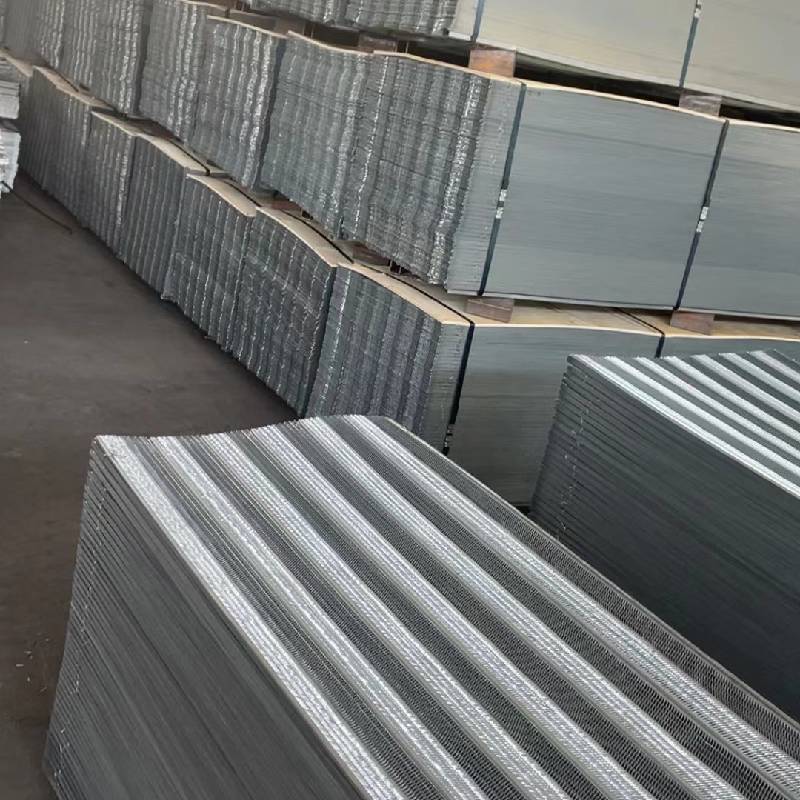

chicken mesh for sale

Evaluating the fluctuating trends of chicken mesh prices, several critical factors must be considered to understand the market dynamics. As an indispensable tool in both agricultural and construction settings, chicken mesh serves crucial functions, from protecting enclosures to reinforcing structures. The price of this versatile product can be impacted by raw material costs, manufacturing processes, and global demand cycles.

Furthermore, economic policies and trade agreements significantly influence prices through tariffs and import-export regulations. The imposition of import duties can either buffer local industries or increase end-user prices, depending on the balance of domestic production versus reliance on imports. Market participants must navigate these regulatory landscapes to optimize sourcing strategies, ensuring cost efficiency whether sourcing locally or internationally. Sustainability concerns also impact the chicken mesh market. As consumers and industries move toward sustainable choices, manufacturers are exploring eco-friendly materials and processes. The transition to less polluting methods and recyclable materials may raise initial costs but also offers long-term savings and alignments with global sustainability standards. Companies adopting green manufacturing could potentially have a competitive edge, making their products more attractive to environmentally conscious buyers despite initial cost hurdles. For consumers and small-business owners purchasing chicken mesh, it is essential to monitor these multifactorial elements impacting price. Collaboration with reliable suppliers offering transparency in their pricing models can help manage budgets effectively. Establishing long-term contracts or bulk purchase agreements with reputable suppliers might offer price stability and shield against unexpected market volatilities. In conclusion, understanding chicken mesh pricing requires a holistic approach considering raw material costs, production efficiencies, global demand cycles, regulatory frameworks, and sustainability trends. By staying educated and proactive, buyers can navigate this complex landscape efficiently, ensuring they obtain durable, cost-effective solutions designed to meet precise industry requirements. This strategic perspective fosters not only better purchasing decisions but also contributes to a more stable supply chain that benefits the entire market ecosystem.

Furthermore, economic policies and trade agreements significantly influence prices through tariffs and import-export regulations. The imposition of import duties can either buffer local industries or increase end-user prices, depending on the balance of domestic production versus reliance on imports. Market participants must navigate these regulatory landscapes to optimize sourcing strategies, ensuring cost efficiency whether sourcing locally or internationally. Sustainability concerns also impact the chicken mesh market. As consumers and industries move toward sustainable choices, manufacturers are exploring eco-friendly materials and processes. The transition to less polluting methods and recyclable materials may raise initial costs but also offers long-term savings and alignments with global sustainability standards. Companies adopting green manufacturing could potentially have a competitive edge, making their products more attractive to environmentally conscious buyers despite initial cost hurdles. For consumers and small-business owners purchasing chicken mesh, it is essential to monitor these multifactorial elements impacting price. Collaboration with reliable suppliers offering transparency in their pricing models can help manage budgets effectively. Establishing long-term contracts or bulk purchase agreements with reputable suppliers might offer price stability and shield against unexpected market volatilities. In conclusion, understanding chicken mesh pricing requires a holistic approach considering raw material costs, production efficiencies, global demand cycles, regulatory frameworks, and sustainability trends. By staying educated and proactive, buyers can navigate this complex landscape efficiently, ensuring they obtain durable, cost-effective solutions designed to meet precise industry requirements. This strategic perspective fosters not only better purchasing decisions but also contributes to a more stable supply chain that benefits the entire market ecosystem.

share:

Next:

Latest news

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025

-

Wall Ties: Invisible Guardians of Building StabilityNewsAug.04,2025

-

Resilient Web: The Super Guardian Power of Concrete MeshNewsAug.04,2025

-

Masonry Accessories: A versatile assistant on building foundationsNewsAug.04,2025

-

Iron Binding Wire: the 'invisible reinforcement specialist' in the fields of architecture and industryNewsAug.04,2025

-

Dynamic Spring: The diverse functions and excellent performance of Wire Tension SpringNewsAug.04,2025

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025