- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Feb . 02, 2025 04:45

Back to list

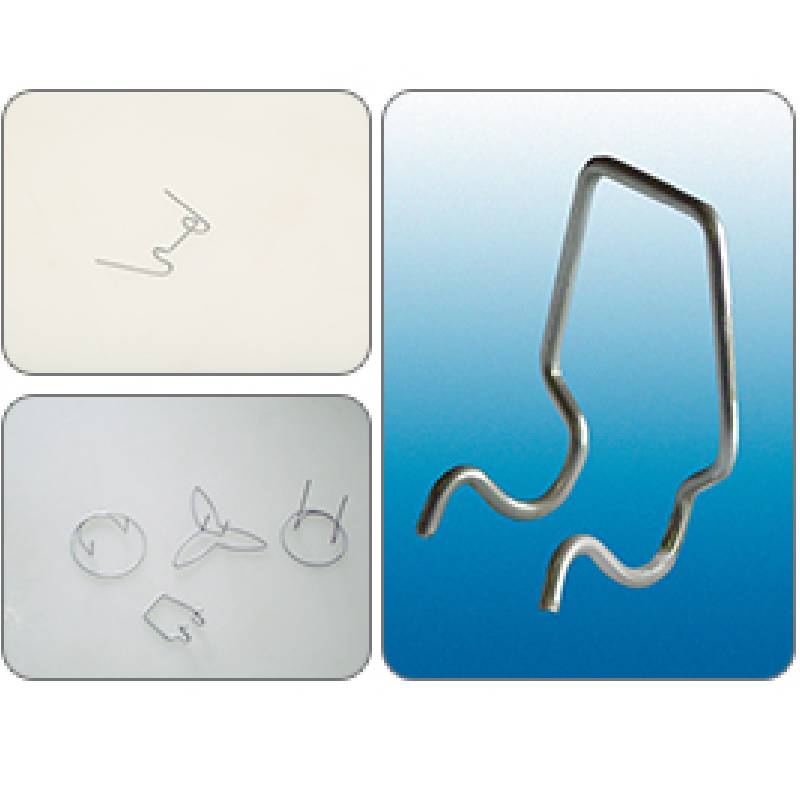

Brick reinforcement mesh

Chicken mesh for brick walls might seem like a niche product, but it is a fundamental component in the construction industry, playing a vital role in achieving durability and stability. The use of chicken mesh in construction has grown in popularity due to its versatility, cost-effectiveness, and ease of installation. While traditionally associated with agricultural use, this material has proven its worth in construction projects, providing essential reinforcement that ensures the integrity and longevity of brick structures.

The authoritative guidance on using chicken mesh in brick wall construction lies in its application technique. Installing chicken mesh involves careful preparation of the surface and precise attachment, ensuring it's taut and secure. Construction professionals advise anchoring the mesh with appropriate fasteners, ensuring it sits snugly between the brick surface and the plaster overlay. This not only ensures maximum adhesion but also extends the lifespan of the plaster finish. Trustworthiness in the use of chicken mesh is echoed through industry endorsements and standardizations. Recognized in building codes and by industry authorities, the methodical use of chicken mesh demonstrates best practice in maintaining the quality and durability of brick walls. Contractors and builders who adhere to these standards offer assurance to clients of a construction project that will withstand the tests of time and elements. Furthermore, incorporating chicken mesh into brick wall construction can also contribute to the eco-friendliness of a project. Since it reduces the need for frequent repairs and replacements, it aligns with sustainable building practices, minimizing waste and resource use over a building’s lifecycle. In summary, chicken mesh for brick walls is not just an optional upgrade; it is an essential element that contributes significantly to the resilience and longevity of a structure. Expert application of this material safeguards against plaster cracking and ensures a durable finish, making it indispensable in both residential and commercial construction. Through authoritative expertise, the appropriate use of chicken mesh remains a testament to effective and sustainable building practices, reinforcing trust in modern construction methodologies.

The authoritative guidance on using chicken mesh in brick wall construction lies in its application technique. Installing chicken mesh involves careful preparation of the surface and precise attachment, ensuring it's taut and secure. Construction professionals advise anchoring the mesh with appropriate fasteners, ensuring it sits snugly between the brick surface and the plaster overlay. This not only ensures maximum adhesion but also extends the lifespan of the plaster finish. Trustworthiness in the use of chicken mesh is echoed through industry endorsements and standardizations. Recognized in building codes and by industry authorities, the methodical use of chicken mesh demonstrates best practice in maintaining the quality and durability of brick walls. Contractors and builders who adhere to these standards offer assurance to clients of a construction project that will withstand the tests of time and elements. Furthermore, incorporating chicken mesh into brick wall construction can also contribute to the eco-friendliness of a project. Since it reduces the need for frequent repairs and replacements, it aligns with sustainable building practices, minimizing waste and resource use over a building’s lifecycle. In summary, chicken mesh for brick walls is not just an optional upgrade; it is an essential element that contributes significantly to the resilience and longevity of a structure. Expert application of this material safeguards against plaster cracking and ensures a durable finish, making it indispensable in both residential and commercial construction. Through authoritative expertise, the appropriate use of chicken mesh remains a testament to effective and sustainable building practices, reinforcing trust in modern construction methodologies.

share:

Next:

Latest news

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025