- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

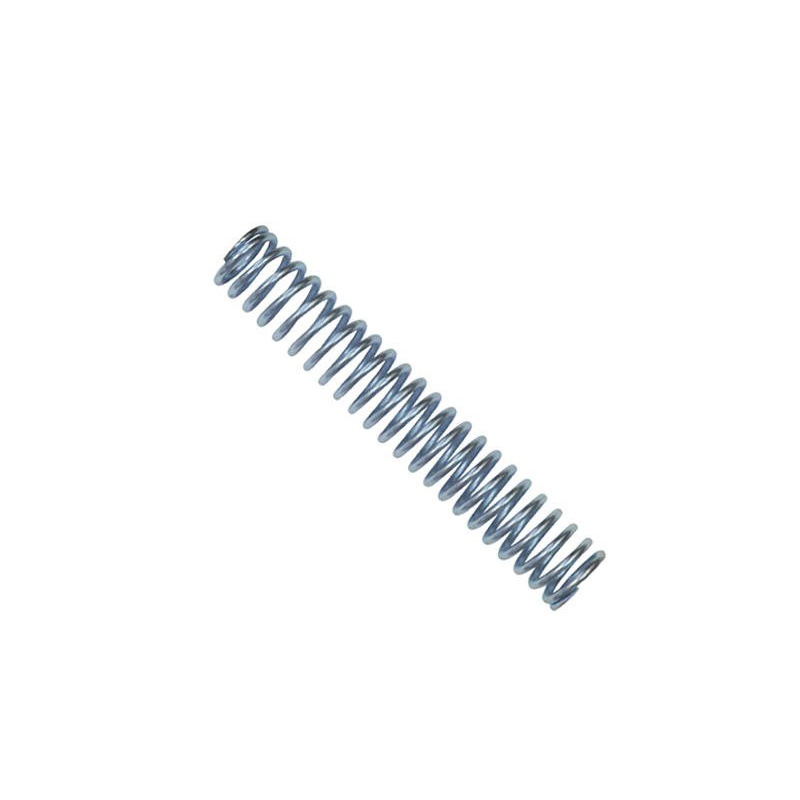

Buy High-Quality Compression Coil Springs for Sale - Best Prices!

The global market for compression coil springs for sale continues to expand with an anticipated CAGR of 5.8% through 2028, driven by increasing automation in manufacturing and transportation sectors. As mechanical components essential for energy storage and motion control, these springs serve as fundamental elements across aerospace, automotive, industrial machinery, and medical device applications.

Conical springs for sale and tapered compression spring varieties have gained significant traction in space-constrained applications where variable spring rates are required. The growing demand for specialized stainless steel compression springs in corrosive environments has pushed manufacturers to develop advanced materials with enhanced fatigue resistance.

Expertise Note: Leading manufacturers like SHIJIAZHUANG TANGCHAO METAL PRODUCTS CO.,LTD. leverage computer-aided design and precision CNC coiling machines to produce springs that consistently meet international standards including DIN, ISO, and ASTM specifications.

Explore premium quality compression coil springs for sale at competitive prices. Our product line includes standard and custom-designed helical compression spring solutions for diverse industrial applications.

➤ View our full catalog: cntcmetal.com/compression-springs

Technical Specifications and Design Variations

Technical Specifications of Compression Springs

| Parameter | Range/Grade | Industry Standard | Design Consideration |

|---|---|---|---|

| Materials | Music Wire, ASTM A228 | Stainless Steel 302/304/316 | Chrome Silicon | DIN 17223 | EN 10270 | ASTM A313 | Corrosion resistance and strength |

| Wire Diameter | 0.1mm - 20mm | ISO 8458-1 | Precision machinery applications |

| Outer Diameter | 0.5mm - 300mm | DIN 2095 | Space constraints in assemblies |

| Spring Rate | 0.1 - 500 N/mm | ISO 2162 | Required force for deflection |

| Free Length | 1mm - 1000mm | BS EN 13906 | Pre-compression requirements |

| Load Capacity | Up to 15,000 N | ASTM B197 | Dynamic vs. static applications |

| Temperature Range | -200°C to +300°C | ASTM F2384 | Extreme environment applications |

| Certification | ISO 9001:2015 | ISO 14001 | ISO 9001 | Quality management standards |

Material Distribution in Industrial Applications

Failure Analysis: Primary Causes in Compression Springs

Design optimization techniques have revolutionized spring manufacturing, particularly for specialized conical springs for sale which provide up to 40% space savings compared to traditional springs. The precision engineering of wire compression springs ensures consistent force curves and deflection characteristics essential for high-accuracy applications.

Surface treatments play a crucial role in spring performance. Shot peening induces beneficial compressive stresses that enhance fatigue life by up to 50% while zinc-nickel coatings on stainless steel compression springs provide optimal corrosion protection in saline environments.

Application-Specific Spring Solutions

Different industries require specialized spring configurations:

- Aerospace: Tapered compression spring designs provide vibration isolation and shock absorption in extreme environments

- Automotive: Helical compression spring applications in suspension systems and powertrain assemblies

- Medical Devices: Miniature compression springs for sale made from biocompatible alloys

- Industrial Automation: Custom-designed a compressed spring systems with precise spring constants

The unique design of conical springs allows for nesting during compression, providing solutions where traditional helical springs would require excessive installation space. This advantage has led to increased conical springs for sale in compact medical device applications.

Technical FAQ: Compression Spring Fundamentals

Global Manufacturing Excellence

SHIJIAZHUANG TANGCHAO METAL PRODUCTS CO.,LTD. specializes in precision spring manufacturing with 17 years of industrial experience. Our facility houses advanced CNC coiling machines capable of producing springs with tolerances down to ±0.01mm.

ZHONGHUACHENG, ROOM 1518 SOUTH OF WEIMING STREET, QIAOXI DISTRICT

SHIJIAZHUANG CITY, HEBEI PROVINCE, CHINA

sales@cntcmetal.com

Phone:

+8613931874955

cntcmetal.com/compression-springs

Industry Research References

1. "Advances in Spring Manufacturing Technologies" - International Journal of Mechanical Engineering (2022)

https://www.ijmejournal.com/spring-tech-advances

2. "Fatigue Analysis of Conical Compression Springs in Automotive Applications" - SAE Technical Papers (2021)

https://www.sae.org/conical-spring-fatigue

3. "Corrosion Mechanisms in Stainless Steel Springs" - Materials Performance Journal (2023)

https://www.materialsperformance.com/stainless-spring-corrosion

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025