- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

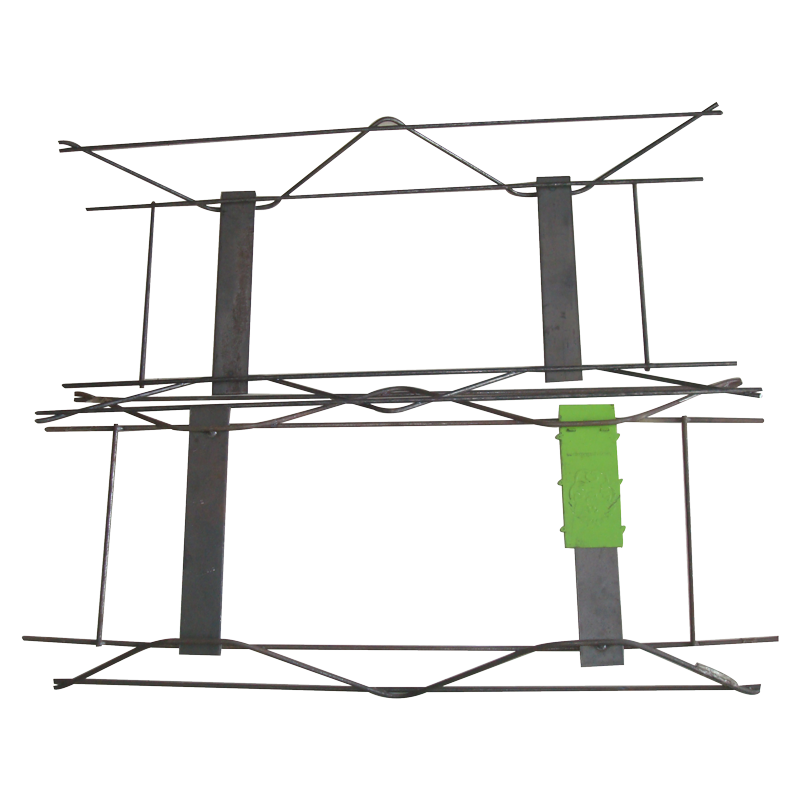

brick cavity ties

Understanding Brick Cavity Ties Importance and Application in Construction

Brick cavity ties, also known as brick ties or cavity wall ties, play a crucial role in modern construction, particularly in the assembly of cavity walls. These components ensure the structural integrity and longevity of buildings while addressing thermal efficiency and moisture management. In this article, we will delve into the importance, materials, installation, and potential issues associated with brick cavity ties.

What Are Brick Cavity Ties?

Brick cavity ties are metal or plastic components used to connect the inner and outer walls of a cavity wall system. This type of wall construction typically features two layers a load-bearing inner leaf (usually made from concrete blocks or brick) and an outer leaf (often made from brick). The space between the two leaves is left as an air gap, known as a cavity. The primary function of cavity ties is to provide stability and structural support by tying the two layers together.

Purpose and Benefits of Cavity Ties

1. Structural Integrity One of the main roles of cavity ties is to ensure that the inner and outer walls act as a single unit. This structural bond helps to resist lateral forces, such as those caused by wind, and prevents the outer leaf from bowing outward.

2. Moisture Control Cavity walls are designed to manage moisture effectively. The cavity itself acts as a drainage channel, allowing any water that penetrates the outer leaf to drain away. Cavity ties help to maintain this drainage pathway by keeping the walls separated, thereby reducing the risk of moisture transfer from the outer leaf to the inner leaf.

3. Thermal Efficiency By facilitating proper insulation placement, cavity ties contribute to the thermal performance of buildings. They can reduce thermal bridging, where heat is lost through the wall ties, making it easier to achieve energy efficiency standards.

4. Durability Made from durable materials, cavity ties are designed to withstand environmental stressors such as corrosion, ensuring that they maintain their function for the lifespan of the building.

Materials Used

Brick cavity ties can be made from various materials, including

- Galvanized Steel This is the most common material used due to its strength and resistance to corrosion. Galvanized steel ties are generally coated with zinc to protect against rust and degradation.

brick cavity ties

- Stainless Steel For environments with high humidity or exposure to salt (such as coastal areas), stainless steel is often recommended due to its superior corrosion resistance.

- Plastic/Composite Materials For thermal efficiency reasons, some ties may be made from non-metallic materials. These ties are beneficial for reducing thermal bridging but may have limitations in strength compared to metal options.

Installation Considerations

The installation of cavity ties must be done with care. Guidelines typically recommend spacing the ties every 600mm vertically and 900mm horizontally. Proper installation includes ensuring that ties are anchored securely to both leaves of the wall and that they are positioned at appropriate heights to support bond patterns and any expected loads.

Common Issues and Solutions

While cavity ties are robust, issues can arise over time, particularly if they are not installed or maintained properly. Common problems include

1. Corrosion Inadequately protected ties can rust over time. Regular inspections can help identify corrosion issues early, and replacing damaged ties is crucial to maintaining structural integrity.

2. Improper Spacing or Installation If cavity ties are spaced too far apart or installed incorrectly, it can lead to structural weaknesses. Adhering to building codes and manufacturer instructions during installation is essential.

3. Moisture Issues If the cavity does not function effectively due to blockages or poor design, moisture issues can develop. Ensuring adequate drainage and inspecting the cavity periodically can mitigate such problems.

Conclusion

Brick cavity ties are an essential component of cavity wall construction, contributing significantly to structural stability, moisture management, and thermal efficiency. Understanding their function, materials, installation requirements, and maintenance will help builders and homeowners achieve durable and efficient buildings. As construction techniques evolve, the role of cavity ties will continue to be relevant, ensuring that structures remain resilient against environmental challenges.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025