- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding the Properties and Applications of Annealed Wire in Various Industries

The Significance of Annealed Wire in Modern Industry

In the vast landscape of materials used in various industrial applications, annealed wire holds a special place due to its unique properties and versatile applications. Annealing is a heat treatment process that alters the physical and sometimes chemical properties of a material, primarily metal, to increase its ductility and reduce its hardness. This process is crucial for producing high-quality wire that can withstand various applications and demands in modern industries.

Annealed wire is produced through a methodical process that involves heating the wire to a specific temperature, followed by a controlled cooling phase. The heating phase allows the atomic structure to rearrange, thereby relieving internal stresses that may have accumulated during the wire's manufacturing. This not only makes the wire more ductile but also enhances its ability to be drawn into thinner strands without breaking. As a result, annealed wire tends to possess improved formability compared to its non-annealed counterparts, making it the preferred choice in many applications ranging from construction to electronics.

One of the primary advantages of annealed wire is its remarkable tensile strength combined with flexibility. Industries that require wire configuration for use in frameworks, fencing, or reinforcement in construction projects find annealed wire particularly beneficial. For instance, in building structures, annealed wire helps ensure that essential components can absorb and distribute certain loads effectively, providing improved durability and safety.

In the field of electronics, annealed wire is crucial for applications like winding coils, connecting components, and more

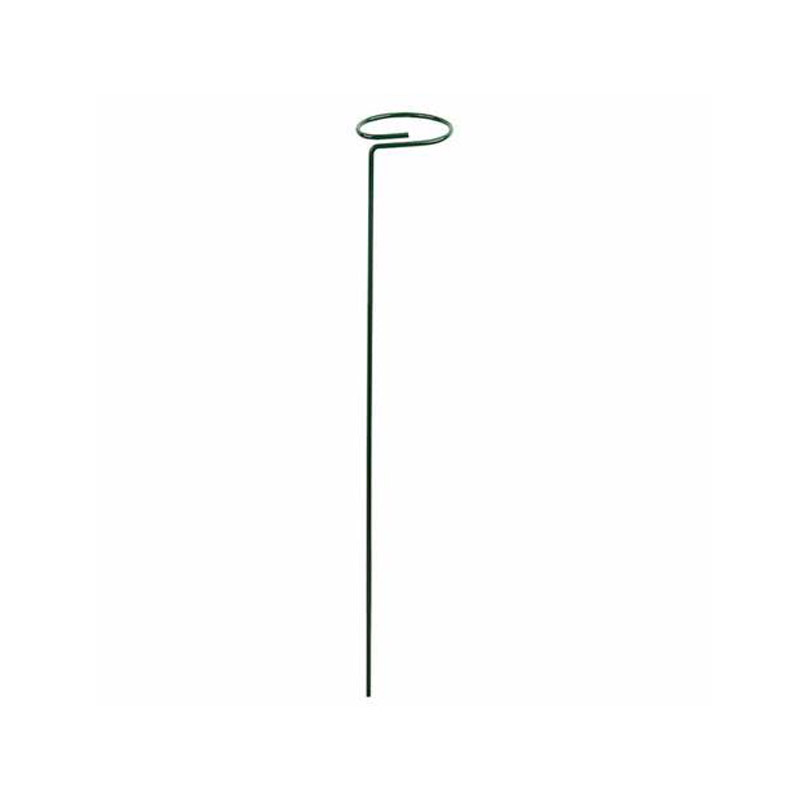

. Its ability to conduct electricity efficiently is enhanced by the annealing process, making it suitable for high-performance applications. Manufacturers often turn to annealed copper wire, which plays a vital role in motors, transformers, and generators due to its excellent electrical conductivity and resistance to oxidation. The annealing process not only enhances the wire's conductivity but also contributes to its resilience against wear, which is particularly important in devices that experience constant mechanical stress.annealed wire

Another industry that benefits significantly from annealed wire is the automotive sector. The production of various automobile parts requires wires with tailored properties to meet stringent safety and performance standards. Annealed wire is utilized in the fabrication of seat belts, brake cables, and other critical components. By ensuring these parts have the right balance of strength and flexibility, manufacturers can enhance the overall safety and reliability of their vehicles.

In addition to its applications in construction, electronics, and automotive sectors, annealed wire is also vital in the manufacturing of springs, fasteners, and other specialized components. The ability to create intricate designs while maintaining structural integrity makes annealed wire indispensable in industries such as aerospace and manufacturing. Springs, which require precise tension and compression responses, benefit immensely from the fatigue resistance offered by annealed wire, ensuring their functionality over an extended life cycle.

Moreover, the versatility of annealed wire extends to artistic and decorative uses. Crafters and artists utilize annealed wire for making jewelry, sculptures, and various other art projects due to its pliability and ease of manipulation. This opens up a world of creative possibilities, further showcasing the material's diverse applications.

As industries continue to evolve, the demand for high-quality materials like annealed wire is expected to rise. A growing focus on sustainability and efficiency in manufacturing processes will further enhance the importance of annealed wire. By offering a balance of strength, flexibility, and conductivity, annealed wire is well-positioned to remain a critical component in many tech-driven and innovative fields.

In conclusion, annealed wire is much more than just a simple material; it is a fundamental building block across multiple industries. Its unique properties, born from the meticulous annealing process, make it a preferred choice for applications requiring reliability and versatility. As we move further into an age defined by technological advancement and material innovation, the role of annealed wire will undoubtedly be integral in shaping the future of manufacturing and engineering. The ability to adapt and respond to the varying needs of different industries ensures that annealed wire will continue to play a significant role for years to come.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025