- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Affordable Chicken Net for Sale - Durable Wire & Mesh Fencing

Understanding Premium Poultry Fencing Solutions for Industrial Applications

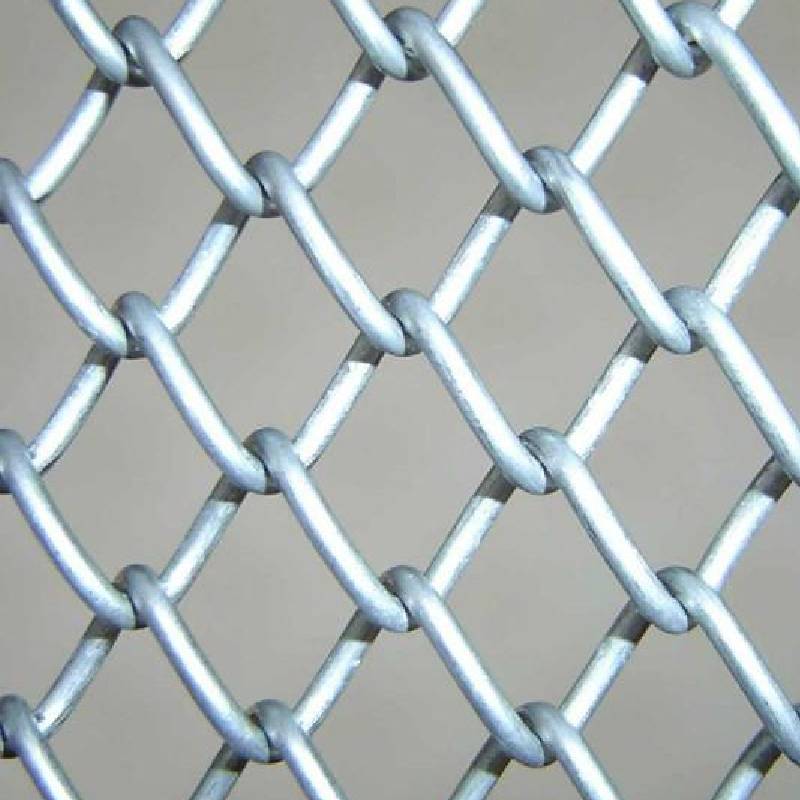

In the agricultural and industrial sectors, the demand for robust and reliable fencing solutions for livestock management, particularly poultry, has seen a significant surge. Businesses are increasingly seeking durable, long-lasting materials that offer both security and cost-effectiveness. When considering options for a secure perimeter, a high-quality chicken net for sale becomes a critical component. This comprehensive guide delves into the technical specifications, manufacturing processes, and diverse applications of advanced poultry fencing, highlighting why selecting the right product is paramount for operational efficiency and animal welfare. We focus on industrial-grade solutions like Chainlink fence mesh, which provides superior strength and longevity compared to traditional light-gauge chicken wire, meeting the stringent requirements of modern farms and industrial facilities.

The market for industrial fencing materials is dynamic, driven by technological advancements in material science and increasing regulatory demands for animal containment. This has led to a greater emphasis on products such as galvanized steel and PVC-coated wire meshes, which offer enhanced resistance to environmental stressors. Whether the requirement is for large-scale commercial poultry farms, secure animal enclosures, or general agricultural partitioning, the choice of fence material directly impacts long-term investment and maintenance overheads. Our expertise lies in delivering solutions that not only meet current industry standards but also anticipate future needs, ensuring our clients receive products that stand the test of time and provide optimal performance.

Industry Trends and Market Insights in Poultry Fencing

The global market for fencing solutions, particularly for agricultural and industrial applications, is experiencing robust growth. Driven by increasing demand for secure and durable enclosures, the segment of chicken net for sale and its variants like chicken wire for sale and chicken mesh for sale continues to expand. Current trends indicate a strong shift towards materials offering superior longevity and minimal environmental impact. For instance, the adoption of galvanized steel and PVC-coated options is on the rise due to their excellent corrosion resistance and extended service life, reducing the frequency of replacements and overall operational costs.

Furthermore, the concept of bulk chicken wire and wholesale chicken wire purchasing is gaining traction among large-scale enterprises and distributors. This approach not only ensures cost efficiencies but also guarantees a consistent supply of high-quality materials for ongoing projects. Innovations in mesh weaving technology are also contributing to the development of stronger, more secure fence designs that can withstand harsh environmental conditions and animal pressures. Businesses are also increasingly concerned with the sustainability of their materials, favoring manufacturers who adhere to responsible sourcing and production practices. Understanding these trends is crucial for businesses aiming to invest in future-proof fencing solutions.

Advanced Manufacturing Process and Technical Superiority

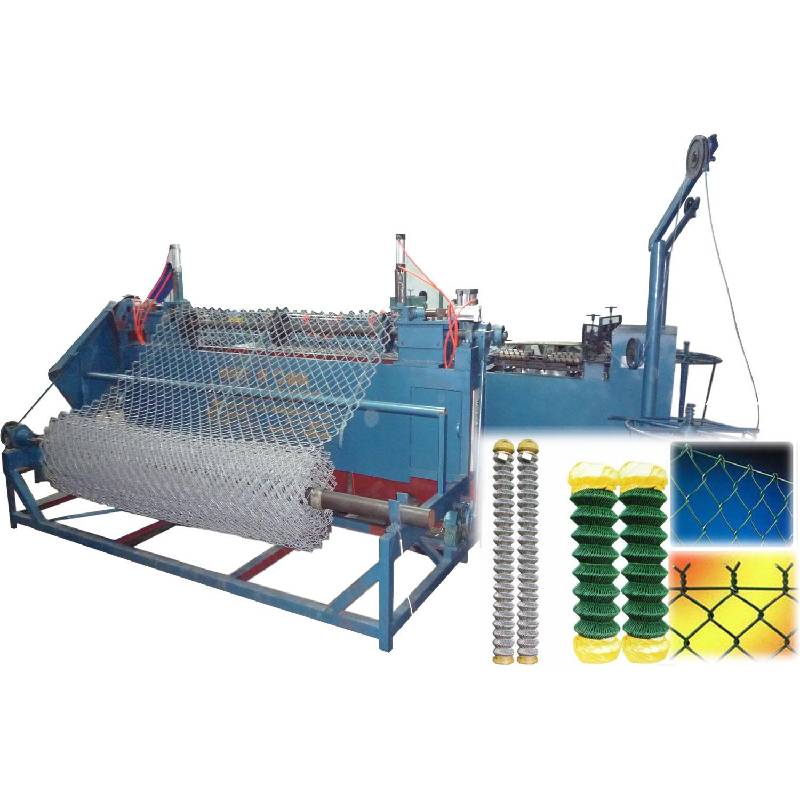

The manufacturing of high-grade poultry fencing for sale, particularly Chainlink fence mesh, involves a sophisticated process designed to ensure durability and optimal performance. The primary material typically used is high-quality steel wire, which undergoes a rigorous wire drawing process to achieve precise diameters. This process enhances the tensile strength and uniformity of the wire, which are critical for the structural integrity of the final mesh. Following wire drawing, the wires are fed into automated weaving machines that interlock them into the characteristic diamond pattern of chainlink mesh. The precision of this weaving ensures consistent mesh size and prevents unraveling, a common issue with lower-quality products.

Post-weaving, the mesh undergoes crucial surface treatments. The most common and effective method is galvanization, where the steel mesh is hot-dipped in molten zinc. This creates a metallurgical bond, providing an extremely durable, anti-corrosive layer that protects the steel from rust and environmental degradation. For enhanced protection and aesthetic appeal, some Chainlink fence mesh products receive a PVC coating applied over the galvanized layer. This adds another barrier against moisture, chemicals, and UV radiation, significantly extending the fence’s service life, especially in harsh climates. Our products adhere to international standards such as ISO 9001 for quality management, ensuring every batch meets stringent performance criteria and a long service life, typically exceeding 20 years in standard conditions. This makes our solutions ideal for demanding sectors like petrochemical, metallurgy, and water treatment where corrosion resistance is paramount.

Technical Parameters and Specifications of Chainlink Fence Mesh

Selecting the appropriate chicken wire fence for sale or Chainlink fence mesh requires a detailed understanding of its technical parameters. These specifications dictate the fence’s strength, durability, and suitability for specific applications. Key parameters include wire gauge (thickness), mesh size (opening dimensions), roll height, and length. For example, a lower gauge number indicates a thicker, stronger wire, suitable for high-security applications, while a smaller mesh size offers better containment for smaller animals and prevents predator intrusion. The type of coating—galvanized or PVC-coated—also significantly impacts the product's longevity and maintenance requirements.

Below is a table outlining typical specifications for Chainlink fence mesh, commonly considered for robust chicken wire fencing for sale applications. These parameters can be customized to meet diverse project requirements, from large-scale agricultural installations to specialized industrial enclosures. Our products undergo stringent quality control processes, including tensile strength tests and coating thickness measurements, to ensure they meet or exceed industry standards such as ASTM F668 for PVC-coated chainlink fabric and ASTM A392 for galvanized chainlink fabric, providing reliable performance and significant advantages in terms of energy savings and corrosion resistance over standard materials.

| Parameter | Typical Range / Value | Description / Benefit |

|---|---|---|

| Wire Gauge (SWG/AWG) | 12.5 GAUGE (2.5mm) - 9 GAUGE (3.7mm) | Thicker wire for enhanced strength and security against predators. |

| Mesh Size (Diamond) | 2 inch (50mm) - 2.5 inch (63mm) | Optimal for containment, balances visibility with security. |

| Roll Height | 4 ft (1.2m) - 12 ft (3.6m) | Versatile heights for various animal sizes and security levels. |

| Roll Length | 50 ft (15m) - 100 ft (30m) | Standard lengths for efficient installation and reduced waste. |

| Material | Low Carbon Steel / Galvanized Steel | Strong base material, suitable for general and coated applications. |

| Surface Treatment | Hot-Dip Galvanized / Electro Galvanized / PVC Coated | Corrosion resistance, extended lifespan, color options. |

Versatile Application Scenarios and Success Stories

Chainlink fence mesh, often considered a robust upgrade to traditional chicken mesh wire for sale, offers unparalleled versatility across various sectors. While primarily known for agricultural uses, such as defining poultry runs and protecting crops from wildlife, its robust construction makes it suitable for a much broader range of industrial and commercial applications. For instance, in large-scale animal husbandry, it provides secure and durable enclosures for various livestock, ensuring their safety and preventing escape. Its adaptability extends to general property demarcation, temporary construction site barriers, and even industrial security perimeters where a blend of visibility and containment is required.

A notable application case involves a large commercial poultry farm in the Midwest that transitioned from traditional netting to our PVC-coated Chainlink fence mesh. They reported a significant reduction in predator incursions and a dramatic increase in fence lifespan, requiring minimal maintenance over five years compared to annual repairs previously. This improved security led to healthier flocks and better yield, demonstrating the tangible benefits of investing in superior chicken net for sale solutions. Another example is a municipal park that utilized our mesh for creating safe, demarcated areas for pet owners, highlighting its utility beyond pure agriculture. Our client feedback consistently emphasizes the ease of installation and the long-term cost savings due to the product's durability and low maintenance requirements.

Key Advantages and Tailored Customization Options

The primary advantage of choosing industrial-grade Chainlink fence mesh as your chicken net for sale solution lies in its superior durability and security. Unlike lighter alternatives, Chainlink mesh offers robust protection against predators and ensures animal containment, significantly reducing losses and enhancing operational safety. The hot-dip galvanized and PVC-coated options provide exceptional resistance to rust, corrosion, and UV degradation, making them suitable for diverse environmental conditions, from humid coastal regions to arid desert landscapes. This longevity translates into substantial long-term cost savings by minimizing replacement and maintenance expenses, presenting a more economically viable solution for businesses seeking cheap chicken wire for sale without compromising on quality or performance.

Recognizing that every project has unique requirements, we specialize in providing tailored customization solutions. Clients can specify wire gauge, mesh size, roll height, and length to perfectly match their application needs. For specific aesthetic or environmental considerations, PVC coatings are available in various colors beyond the standard green or black. Our engineering team collaborates closely with clients to design bespoke fencing systems, ensuring optimal functionality and integration with existing infrastructure. With over 15 years of experience in the metal mesh industry and ISO 9001 certification, we stand as an authoritative provider of high-quality fencing solutions, backed by rigorous testing and a commitment to customer satisfaction. Our extensive service history and numerous successful projects testify to our reliability and expertise in delivering robust and effective fencing solutions.

Choosing the Right Supplier: Manufacturer Comparison

When sourcing wholesale chicken wire or specialized Chainlink fence mesh, the choice of supplier is as critical as the product itself. A reputable manufacturer offers not just a product, but a complete solution encompassing technical consultation, quality assurance, and reliable post-sales support. Key criteria for evaluating suppliers include their adherence to international manufacturing standards (e.g., ISO certifications), the breadth of their product range, their capacity for custom orders, and their track record for timely delivery. Transparency in material sourcing and production processes also speaks volumes about a manufacturer's commitment to quality and ethical practices.

Prospective buyers should assess a supplier's technical expertise, ensuring they can provide in-depth information on material properties, coating specifications, and installation best practices. Experience in handling large-volume industrial orders, like those for bulk chicken wire, is also a strong indicator of capability and reliability. Furthermore, a strong warranty and responsive customer support signify a supplier's confidence in their product and dedication to client satisfaction. Our commitment to these principles ensures that clients receive not just a fence, but a robust, long-term solution backed by expert support and a dedication to quality that sets us apart in the industry.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lifespan of Chainlink fence mesh for poultry applications?

A: With proper installation and maintenance, our hot-dip galvanized Chainlink fence mesh typically lasts 15-20 years. PVC-coated options can extend this lifespan further, often exceeding 25 years, due to enhanced protection against corrosion and UV degradation, making it a very durable choice for a chicken net for sale.

-

Q: Can your Chainlink fence mesh be customized for specific animal sizes?

A: Absolutely. We offer customization options for mesh size and wire gauge to ensure optimal containment for various animals, from small fowl to larger livestock. This ensures effective containment and predator deterrence tailored to your specific needs, even for demanding chicken wire fence for sale requirements.

-

Q: What are your typical delivery lead times for bulk orders?

A: Delivery times vary based on order volume and customization requirements. For standard products, lead times generally range from 2-4 weeks. For large bulk chicken wire orders or highly customized specifications, we provide an estimated timeline during the quotation phase, striving to meet project deadlines efficiently.

Delivery Timelines and Quality Assurance

Understanding the critical nature of project timelines, we streamline our production and logistics to ensure efficient delivery of all orders, from single rolls of chicken net for sale to large-scale industrial supplies. Our robust supply chain management and manufacturing capabilities allow us to provide clear and reliable delivery schedules. Standard lead times for common specifications are typically provided upfront, with expedited options available for urgent requirements, subject to capacity. We prioritize communication, keeping our clients informed at every stage of their order, from production commencement to dispatch and transit updates.

Quality assurance is at the core of our operations. Every batch of Chainlink fence mesh undergoes stringent quality control checks, adhering to international standards like ISO 9001. This includes inspection of wire gauge consistency, mesh integrity, coating thickness, and overall finish. We offer a comprehensive warranty against manufacturing defects, underscoring our confidence in product durability and performance. Our dedicated customer support team is available to address any queries or provide technical assistance, ensuring complete satisfaction and a seamless experience for all our clients seeking durable and reliable fencing solutions.

References

- American Society for Testing and Materials (ASTM) Standards for Fencing Materials.

- International Organization for Standardization (ISO) 9001: Quality Management Systems.

- Journal of Agricultural Engineering Research on Livestock Enclosures.

- Agricultural Policy Institute Reports on Sustainable Farming Practices.

share:

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025

-

Timber Frame Wall Ties: Stable Bonds for Load TransmissionNewsAug.08,2025

-

Stainless Steel Woven Wire Mesh: A versatile material from boundary protection to functional supportNewsAug.08,2025

-

Powder Coat Coil Springs: Creating peace of mind and reliability with sturdy protectionNewsAug.08,2025

-

Floor Standing Sign Holder: A Powerful Assistant for Flexible DisplayNewsAug.08,2025

-

Binding Iron Wire: An Invisible Bond for Building StabilityNewsAug.08,2025

-

Yard Sign Stakes: Reliable Guardians of Outdoor SignsNewsAug.04,2025