- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

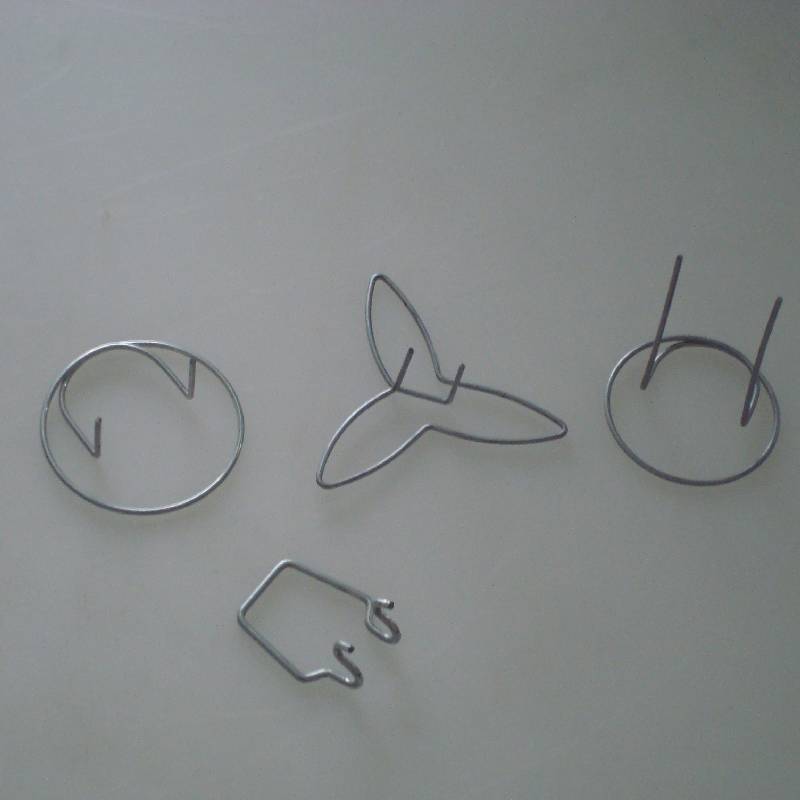

5 inch compression spring

Understanding the 5% Compression Spring A Comprehensive Overview

Compression springs are an integral component of various mechanical systems, offering essential functions in applications ranging from automotive engineering to consumer electronics. Among these, a 5% compression spring stands out for its unique characteristics and applications. This article delves into the specifics of this type of spring, its functionality, and its importance in design and engineering.

What is a Compression Spring?

A compression spring is a type of spring that resists linear compressive forces. Typically made of coiled wire, these springs are designed to compress under load and return to their original length when the force is removed. They are widely used in applications where space is limited and mechanical resilience is required.

The 5% Compression Spring Defined

The term 5% compression spring denotes a spring that can be compressed to a degree of up to 5% of its free length under load without permanent deformation. For instance, if the spring has a free length of 100 mm, a 5% compression would allow it to be compressed to 95 mm during operation. This specification is crucial for engineers who are designing systems where precise control over spring functionality is necessary.

Benefits of 5% Compression Springs

5 inch compression spring

2. Space Efficiency With a compact design, a 5% compression spring is ideal for applications with limited space, allowing for more compact designs without sacrificing functionality.

3. Durability When designed correctly, these springs can deliver high fatigue resistance. This means they can undergo numerous compressive cycles without failing, making them suitable for various applications where reliability is paramount.

4. Versatility The 5% compression spring can be utilized across multiple industries, including aerospace, automotive, and even in everyday household items like pens and mattresses.

Applications

The applications of 5% compression springs are vast. In the automotive industry, they are used in suspension systems to provide a smooth ride and absorb shocks. In consumer electronics, they appear in devices like key switches or mechanisms where a gentle, responsive touch is necessary. Furthermore, in industrial machinery, these springs can facilitate the operation of clamping mechanisms, latches, and various assembly components.

Conclusion

The 5% compression spring is a crucial element in modern engineering that meets a wide array of functional requirements. Its ability to compress, store energy, and return to its original form makes it indispensable in various applications. As technology advances, the role of compression springs, particularly those with specific compression percentages, will likely continue to grow, driving innovation and efficiency across multiple sectors. Whether you are designing intricate machinery or simple mechanical devices, understanding the characteristics and functions of a 5% compression spring can greatly enhance your project's success.

share:

-

Strong Wall Support ChoicesNewsMay.23,2025

-

Strong Stakes, Big SupportNewsMay.23,2025

-

Spring Solutions for Smart DesignNewsMay.23,2025

-

Smart Choices in Concrete AccessoriesNewsMay.23,2025

-

Practical Mesh Fencing Choices for Modern SpacesNewsMay.23,2025

-

Iron Wire Solutions for Practical ProtectionNewsMay.23,2025

-

The Ultimate Solution for Display Needs: Wire Grid PanelsNewsMay.06,2025