- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

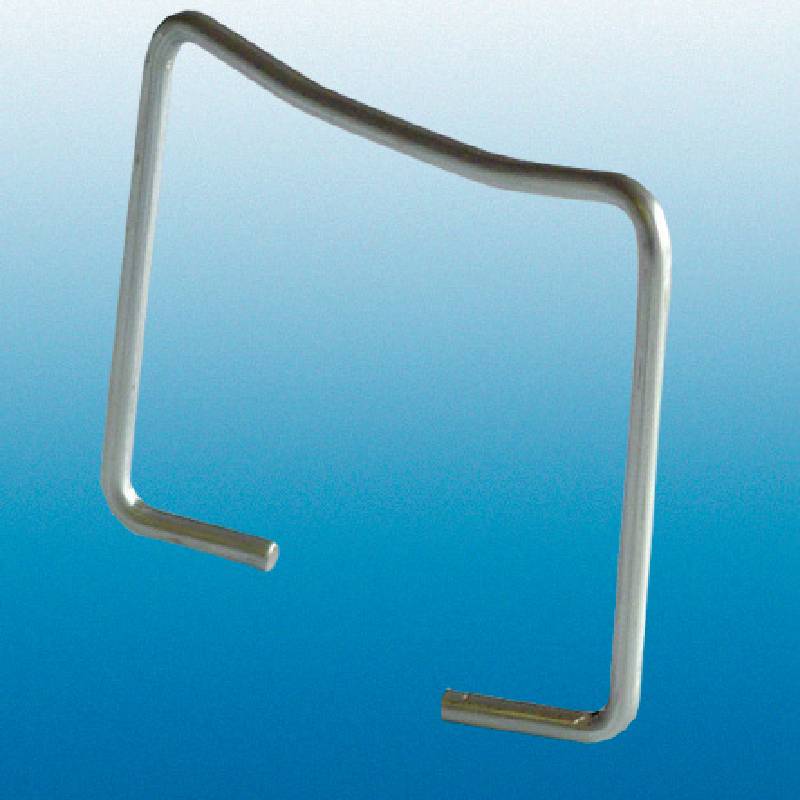

3 8 compression spring

Understanding 3 8% Compression Springs

Compression springs are crucial components in various mechanical systems, playing a vital role in numerous applications ranging from automotive to industrial machinery. Among these, the 3 8% compression spring stands out for its unique specifications and features that make it particularly effective in specific contexts.

Understanding 3 8% Compression Springs

The designation 3 8% typically refers to specific dimensions and material properties of the spring. The 3% can denote the percentage of compression that the spring can endure without permanent deformation, meaning that the spring can compress by 3% of its total length while still returning to its original state. The 208% indicates the maximum load capability of the spring relative to its pre-compressed position.

3 8 compression spring

Compression springs like the 3 8% are commonly manufactured from high-carbon steel or stainless steel due to their durability and resistance to wear and fatigue. The choice of material is critical as it directly impacts the spring's performance, lifespan, and applicability in harsh environments. Additionally, these springs can be designed with varying coil diameters, free lengths, and wire diameters to suit specific usage conditions.

One of the most important applications for the 3 8% compression spring is in automotive systems. They can be found in shock absorbers, valve assemblies, and various suspension components, helping to absorb shocks and maintain stability in vehicles. In industrial machinery, they serve functions in safety devices, actuators, and control systems, where precise force application is required.

The design and manufacturing process of such springs require precision engineering. Factors such as stress concentrations, tolerances, and load specifications must be carefully calculated to ensure reliability and efficiency during operation. Moreover, quality assurance measures are essential during production to prevent mechanical failures that could lead to significant operational downtime.

In summary, the 3 8% compression spring is a specific type of spring that exemplifies the importance of material properties, design specifications, and engineering precision in the development of mechanical systems. Its effectiveness across various industries underscores the significance of compression springs as foundational components in both everyday applications and complex machinery. Understanding their characteristics allows for optimized performance in numerous engineering solutions.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025