- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

Understanding the Characteristics and Applications of 1 Inch Compression Springs in Mechanisms

Understanding 1% Compression Springs Characteristics and Applications

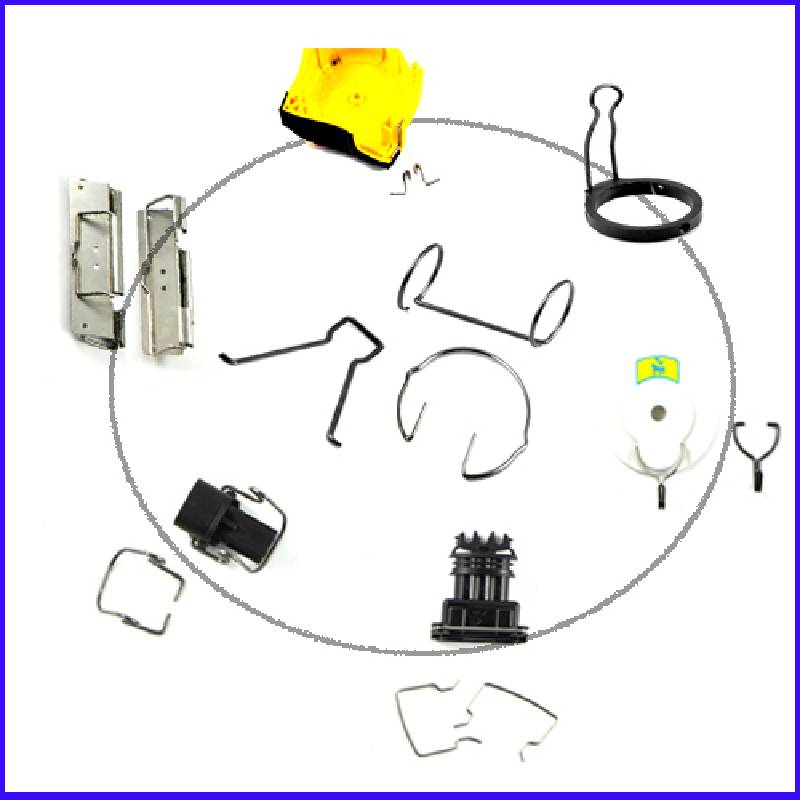

Compression springs are mechanical devices designed to carry loads in static or dynamic conditions by providing resistance in compression. Among these springs, the 1% compression spring is a widely used variant, defined by its ability to exert significant force while compressing 1% of its free length. These springs find applications across various industries, thanks to their specific design and operational characteristics.

Characteristics of 1% Compression Springs

1% compression springs are typically made from high-quality materials such as stainless steel, carbon steel, or alloy steel, ensuring durability and strength under substantial loads. The primary characteristic that sets the 1% compression spring apart is its rate of compression. The 1% designation indicates that the spring is designed to compress no more than 1% of its original length while still maintaining its functionality. This feature is particularly important in applications where space is constrained, such as in small machinery or electronic devices.

Moreover, these springs exhibit excellent fatigue resistance, allowing them to function effectively over a long lifespan without significant wear. The design also facilitates linear compression, meaning that the force applied to compress the spring is directly proportional to the distance it is compressed. This linearity allows for predictable performance, which is crucial in applications that require precise force measurement and control.

Applications of 1% Compression Springs

Various industries utilize 1% compression springs for different purposes

. Some practical applications include1 inch compression spring

1. Automotive Industry In vehicles, these springs are commonly used in suspension systems, where they help absorb shocks and maintain stability. The 1% compression springs ensure that the ride remains smooth and comfortable while also offering support under weight.

2. Aerospace Industry The aerospace sector relies heavily on lightweight, efficient components. 1% compression springs are ideal for use in landing gear systems, where their minimal compression allows for robust performance under extreme conditions, including high altitudes and varying temperatures.

3. Consumer Electronics In devices like smartphones and laptops, 1% compression springs can be found in mechanisms such as keyboards and battery compartments. They provide the necessary force for smooth operation and secure closure, enhancing user experience.

4. Medical Devices In the medical field, precision is critical. 1% compression springs are often used in equipment such as surgical instruments and diagnostic devices, where they contribute to the accurate movement and functioning of movable parts.

5. Industrial Machinery In manufacturing and assembly lines, these springs can help in various applications, such as actuation and safety mechanisms. Their ability to deliver consistent force makes them valuable in ensuring operational efficiency.

Conclusion

The 1% compression spring serves as a vital component in numerous applications across different industries. Its unique characteristics, including durability, fatigue resistance, and predictable performance, make it an ideal choice for situations demanding reliability and efficiency. As technology advances, these springs will likely evolve, paving the way for even more innovative applications in the future. Whether in cars, airplanes, or everyday devices, the humble 1% compression spring remains an unsung hero of modern engineering.

share:

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025

-

The Structural Dynamics of Modern Concrete: How Snake Spacers Revolutionize Flexible ReinforcementNewsJun.06,2025

-

Snake Spacers Smart-Lock Concrete Reinforcement with Surgical PrecisionNewsJun.06,2025

-

Snake Spacers: Reinforcement Precision for Modern Concrete ProjectsNewsJun.06,2025

-

Snake Spacers Powering Concrete's Structural DNANewsJun.06,2025

-

Slither into Success: Snake Spacers' Precision Bite for Unbreakable ReinforcementNewsJun.06,2025

-

Sacrificial Formwork: Building Stronger, Faster, and Safer StructuresNewsJun.06,2025