- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

10 gauge galvanized steel wire

Understanding 10% 20 Gauge Galvanized Steel Wire

When it comes to construction and various industrial applications, materials selection plays a crucial role in ensuring durability and effectiveness. Among the many materials available, 10% 20 gauge galvanized steel wire stands out for its combination of strength, flexibility, and resistance to corrosion. In this article, we will explore the characteristics, uses, and benefits of this versatile wire.

What is 20 Gauge Galvanized Steel Wire?

The term 20 gauge refers to the thickness of the wire. Wire gauge is a standard unit of measurement that indicates the diameter; a lower gauge number signifies a thicker wire. Therefore, 20 gauge is thinner compared to lower numbers but thicker than higher gauge options. The galvanized aspect means that the wire has been coated with a layer of zinc to protect against rust and corrosion, making it suitable for various environments, including outdoor settings where moisture is a concern.

The Significance of the 10% Specification

When we refer to 10% 20 gauge galvanized steel wire, it typically indicates a specific strength characteristic or tensile strength rating of the wire. The 10% may denote a particular elongation percentage or a specification related to the yield strength, which is crucial for determining how much load the wire can bear without deformation. This information is vital for engineers and builders who assess the suitability of materials for specific applications.

Applications of 20 Gauge Galvanized Steel Wire

1. Fencing and Agricultural Uses One of the most common applications of galvanized steel wire is in fencing. For agricultural purposes, it is often used to construct livestock fencing and garden fences due to its strength and resistance to rust, ensuring longevity in various weather conditions.

10 gauge galvanized steel wire

2. Crafting and DIY Projects The flexibility of 20 gauge wire makes it an excellent choice for crafting. Artists and hobbyists use this wire for creating sculptures, jewelry, and other decorative items. Its manageable thickness allows for intricate work while providing enough strength to hold shapes well.

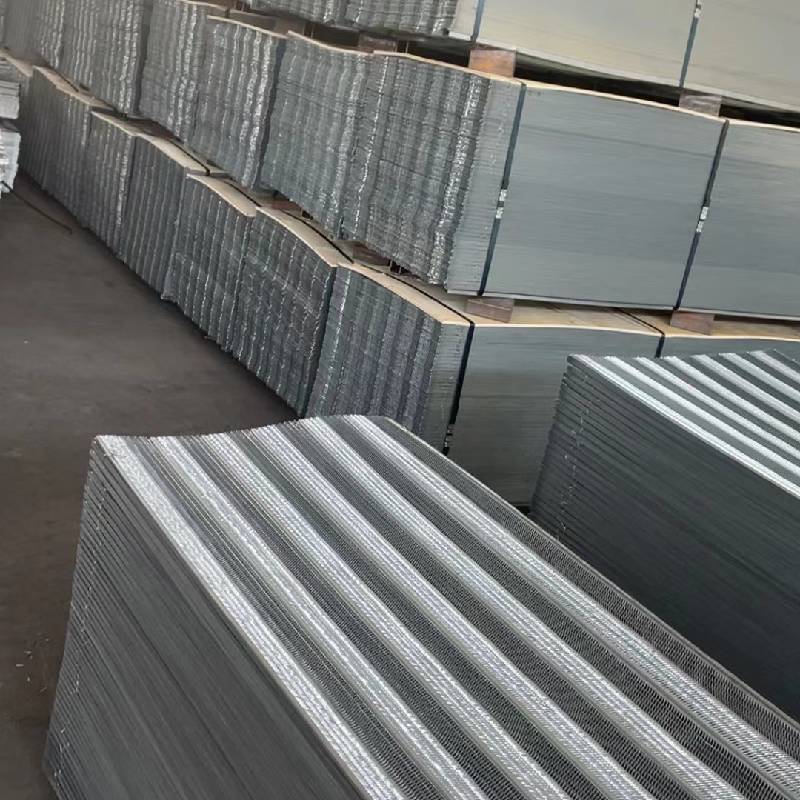

3. Construction and Support Structures In construction, galvanized steel wire is often used for reinforcing concrete, as part of wire mesh, or as tie wire for holding structural elements together. Its corrosion resistance makes it ideal in environments where it may be exposed to moisture.

4. Industrial Applications In the industrial sector, this type of wire is used in various settings, from electrical applications to mechanical uses, such as springs and connectors. The enhanced durability provided by the galvanized coating is particularly valuable in harsh working environments.

Benefits of Using Galvanized Steel Wire

The primary benefit of using 10% 20 gauge galvanized steel wire lies in its corrosion resistance. The zinc coating significantly extends the life of the wire, making it a cost-effective choice over the long term. Additionally, its high tensile strength means that it can withstand heavy loads and stress, reducing the likelihood of failure in critical applications.

Moreover, the versatility of this wire allows it to be used in a wide range of applications, from simple gardening projects to sophisticated construction tasks. Combined with its affordability and availability, galvanized steel wire is a staple in many industries.

Conclusion

In conclusion, 10% 20 gauge galvanized steel wire represents a reliable and versatile material that meets the demands of various applications. Its combination of strength, durability, and resistance to environmental factors makes it an ideal choice for both professional and DIY projects. Understanding its properties and uses can help individuals and businesses make informed decisions about their material needs, ensuring the success of their projects.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025