- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

pvc galvanized wire

Understanding PVC Coated Galvanized Wire Properties and Applications

PVC (Polyvinyl Chloride) coated galvanized wire is a versatile and durable material that has found numerous applications across various industries. This product combines the strength and corrosion resistance of galvanized wire with a protective layer of PVC, enhancing its longevity and usability in different environments.

Understanding PVC Coated Galvanized Wire Properties and Applications

One of the significant advantages of PVC coated galvanized wire is its aesthetic appeal. The PVC comes in various colors, allowing the wire to blend seamlessly into different surroundings or be easily identified for specific applications. This makes it a popular choice for fencing, where both functionality and visual appeal are important. With options for green, black, and other colors, PVC coated wire can be used in residential areas, gardens, and commercial properties without detracting from the landscape.

pvc galvanized wire

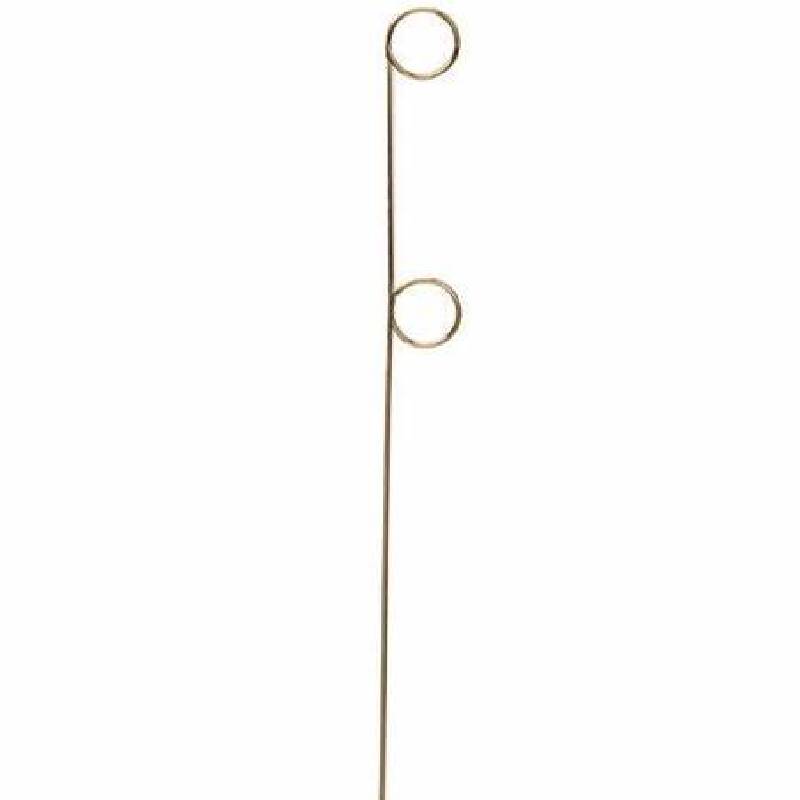

In terms of applications, PVC coated galvanized wire is commonly used in agricultural settings for fencing livestock, securing gardens, or creating trellises for climbing plants. It is also used in construction for reinforcing concrete, as it offers both strength and flexibility. Additionally, the wire is utilized in manufacturing industrial products, such as wire baskets and containers, due to its durability.

However, it is essential to consider the environmental impact when choosing materials for various projects. PVC, while beneficial in many ways, is a plastic that can contribute to environmental pollution if not disposed of properly. Therefore, it’s crucial to look for recycling options where possible and to be mindful of the life cycle of these materials.

In conclusion, PVC coated galvanized wire represents a perfect blend of strength, durability, and aesthetics. Its wide range of applications makes it an invaluable resource in both residential and industrial settings, proving that practical solutions can also be visually pleasing. As industries continue to seek sustainable practices, the use of such materials should be carefully evaluated to balance functionality with environmental responsibility.

share:

-

Your Source for Concrete Wall Ties and Masonry AccessoriesNewsJul.10,2025

-

Unlocking the Power of Iron Wire for Every ProjectNewsJul.10,2025

-

Explore Advanced Chain Wire and Stainless Steel Mesh FencingNewsJul.10,2025

-

Discover the Benefits of Annealed Wire ProductsNewsJul.10,2025

-

Discover China Stainless Steel Wire Mesh SolutionsNewsJul.10,2025

-

Build with Confidence Using High-Performance Masonry AccessoriesNewsJul.10,2025

-

Why Sacrificial Formwork Is Redefining Underground ConstructionNewsJun.06,2025