- Mobile Phone

- +8613931874955

- sales@cntcmetal.com

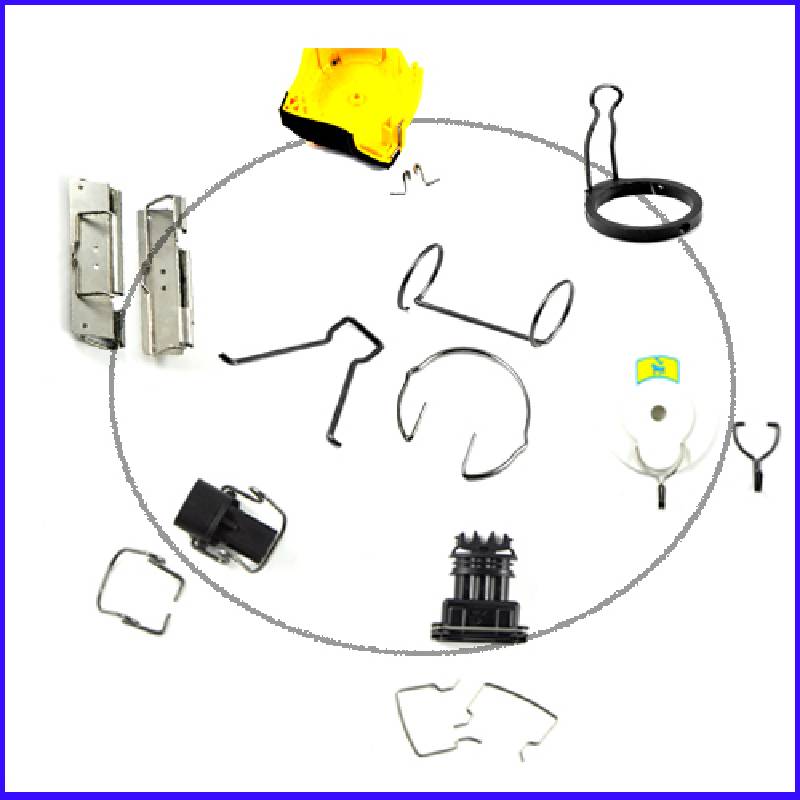

Precision Custom Wire Forming Manufacturer | Expert Services

Driving Precision and Innovation in Industrial Manufacturing

In the intricate world of modern manufacturing, the demand for components that offer unparalleled precision, durability, and cost-efficiency continues to grow. At the forefront of meeting these rigorous requirements is advanced Wire Forming technology. This sophisticated process transforms raw metallic wires into complex, custom-shaped components critical for a vast array of industries, from automotive to aerospace, and medical to telecommunications. Our commitment at CNTC Metal extends beyond mere production; we engineer solutions that integrate cutting-edge technology with deep material science expertise to deliver superior performance.

This article delves into the comprehensive aspects of modern Wire Forming, exploring its detailed process flow, technical advantages, diverse applications, and the strategic considerations for selecting a manufacturing partner capable of delivering high-quality, customized solutions.

The Advanced Manufacturing Process of Wire Forming

The manufacturing of precision Wire Forming components is a meticulously orchestrated process that combines material science, mechanical engineering, and advanced automation. Unlike traditional casting or forging which start with molten metal or solid billets, wire forming begins with high-quality wire stock, making it ideal for creating intricate geometries with high repeatability and minimal material waste.

1. Material Selection and Preparation

The foundation of any superior wire formed component lies in the selection of the correct material. Our expertise covers a wide spectrum of metals, including various grades of stainless steel (e.g., 304, 316, 17-7 PH), high-carbon steel, spring steel, copper alloys, titanium, and exotic alloys like Inconel. Each material is chosen based on its specific mechanical properties, such as tensile strength, yield strength, fatigue resistance, corrosion resistance, and thermal stability, to meet the application's demands. Wire stock undergoes rigorous inspection for surface finish, diameter consistency, and material composition to ensure it meets our stringent internal specifications and relevant industry standards like ASTM, DIN, or JIS.

2. Precision Forming Techniques

Modern wire forming predominantly utilizes highly automated CNC (Computer Numerical Control) wire bending machines. These machines are capable of executing complex 2D and 3D bends with exceptional accuracy. The primary processes involved include:

- Cold Forming: Most wire forming is performed at room temperature, which maintains the material's strength and improves surface finish. This method involves bending, coiling, twisting, and stamping processes.

- CNC Bending: Multi-axis CNC wire formers precisely control the feeding, rotation, and bending of the wire using sophisticated tooling. This allows for intricate geometries, tight tolerances, and efficient production of components from simple hooks to complex spring shapes.

- Cut-to-Length: Wires are precisely cut to the required length before or after forming, depending on the component's design.

- Secondary Operations: These may include chamfering, swaging, threading, or punching for specific functional requirements.

3. Finishing and Quality Assurance

Once formed, components often undergo post-processing to enhance their performance and appearance:

- Heat Treatment: Stress relieving, hardening, or tempering can be applied to optimize mechanical properties, improve ductility, or increase hardness, particularly for spring applications.

- Surface Treatments: Electroplating (e.g., zinc, nickel, chrome), powder coating, passivation, or polishing are common to enhance corrosion resistance, wear resistance, or aesthetic appeal.

- Deburring: Removal of any sharp edges or burrs for safety and improved fit.

4. Industry Standards and Certifications

Our manufacturing processes adhere strictly to international quality and performance standards. This includes, but is not limited to, ISO 9001 for quality management systems, ISO 14001 for environmental management, and where applicable, industry-specific standards such as IATF 16949 for automotive components, AS9100 for aerospace, or ISO 13485 for medical devices. All components undergo comprehensive testing, including dimensional inspection using CMMs (Coordinate Measuring Machines), material hardness testing, tensile strength tests, and salt spray corrosion resistance tests, ensuring a consistent service life and reliability. Our commitment to quality ensures components designed for a specified service life, often exceeding 10 years in typical operational conditions in industries like petrochemical and water supply & drainage, where corrosion resistance is paramount.

Key Technical Parameters and Specifications for Wire Forming

Understanding the critical technical parameters is essential for specifying and manufacturing high-performance wire formed components. These parameters directly influence the component's function, durability, and compatibility within complex assemblies.

Typical Wire Forming Product Specifications

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Wire Diameter | The cross-sectional diameter of the raw wire material. | 0.2 mm to 16.0 mm (0.008" to 0.630") |

| Material Types | Common alloys used for wire forming. | Stainless Steels (302, 304, 316, 17-7 PH), High Carbon Steels (1075, 1095), Spring Steels (5160), Copper Alloys, Titanium, Inconel. |

| Tolerances | Precision achievable for critical dimensions (length, angle, radius). | ±0.05 mm (±0.002") for linear, ±0.5° for angular. Tighter tolerances achievable on request. |

| Surface Finish | Post-forming surface treatment options. | Plain, Electro-polished, Passivated, Powder Coated, Zinc Plated, Nickel Plated. |

| Tensile Strength | Maximum stress a material can withstand before breaking. | Up to 2500 MPa (depending on material and heat treatment) |

| Temperature Range | Operational temperature limits for the formed component. | -60°C to +400°C (depending on material) |

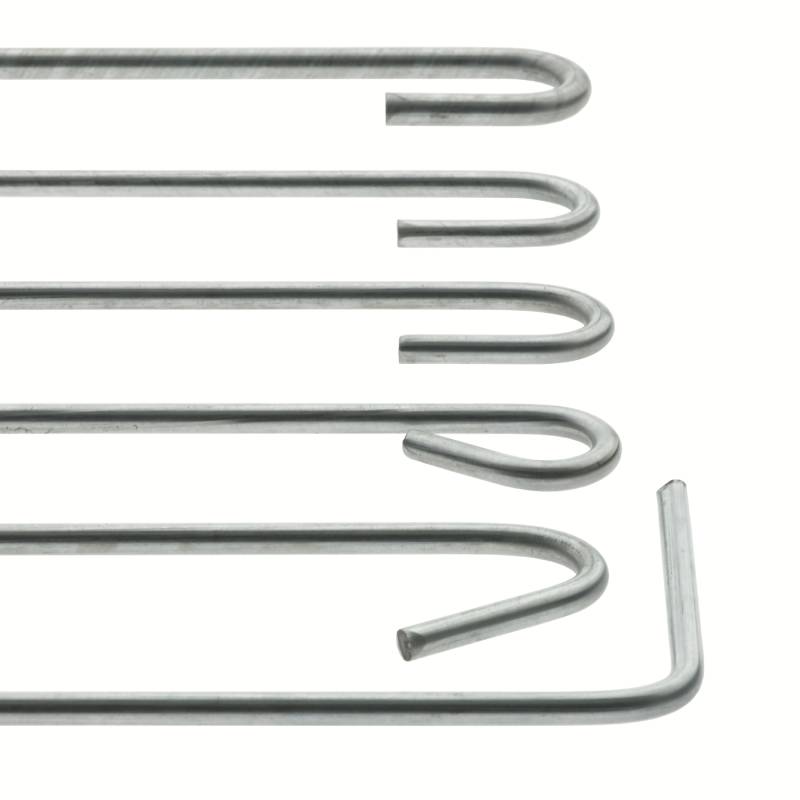

| Forming Capability | Complexity of shapes achievable (2D/3D). | Complex 2D and 3D geometries, closed loops, open hooks, intricate bends. |

These specifications highlight our capability to produce components that meet the most demanding engineering requirements, ensuring optimal performance and longevity in their intended applications.

Industry Trends Shaping Modern Wire Forming

The Wire Forming industry is continuously evolving, driven by advancements in technology, increasing demand for complex components, and a growing emphasis on sustainability. Staying abreast of these trends is crucial for maintaining a competitive edge and delivering future-proof solutions.

- Increased Automation and Robotics: The integration of advanced robotics and fully automated CNC wire bending machines is leading to higher production speeds, reduced labor costs, and enhanced precision. This trend minimizes human error and allows for lights-out manufacturing.

- Additive Manufacturing Integration: While primarily subtractive, wire forming is increasingly complemented by additive manufacturing (3D printing) for prototyping complex tools, fixtures, or even hybrid components, accelerating design iterations.

- Demand for Advanced Materials: The push for lighter, stronger, and more corrosion-resistant components in industries like aerospace and medical is driving the use of specialty alloys (e.g., nitinol, titanium alloys, superalloys) in wire forming.

- Sustainable Manufacturing Practices: Focus on energy efficiency, waste reduction (wire forming typically generates less scrap than machining), and the use of recyclable materials is a growing priority. Manufacturers are adopting greener processes and optimizing material utilization.

- Industry 4.0 and Smart Manufacturing: Integration of IoT, AI, and data analytics for predictive maintenance, real-time process monitoring, and optimized production scheduling is enhancing operational efficiency and quality control in wire forming facilities.

By embracing these trends, CNTC Metal ensures that our Wire Forming solutions remain at the cutting edge, offering clients advanced capabilities and long-term value.

Diverse Application Scenarios and Target Industries

The versatility and precision of Wire Forming make it indispensable across a multitude of industries. Its ability to create complex shapes from various metals makes it ideal for components ranging from structural supports to intricate functional elements.

- Automotive Industry: From seating frames and exhaust hangers to intricate sensor mounts and door lock mechanisms, wire formed components are critical for both structural integrity and functional performance. Advantages include lightweighting for fuel efficiency and corrosion resistance for extended vehicle life.

- Petrochemical and Oil & Gas: Components requiring extreme corrosion resistance and high strength, such as specialized hangers, filters, and internal structural elements for valves and pumps, are frequently wire formed using materials like stainless steel and Inconel. This contributes to energy saving by ensuring reliable, leak-free operation and minimizing maintenance.

- Metallurgy and Heavy Industry: Used for furnace components, material handling equipment, and high-temperature resistant parts where robust and durable wire forms are required.

- Water Supply & Drainage: Stainless steel wire forms are crucial for filter baskets, support grids, and various internal components in water treatment systems, providing excellent corrosion resistance in aquatic environments and ensuring long service life, reducing operational costs.

- Medical Devices: Small, intricate components for surgical instruments, orthodontic devices, and internal medical implants often utilize wire forming for its precision and ability to work with biocompatible materials like titanium and Nitinol.

- Aerospace and Defense: High-performance wire forms are used in aircraft seating, control mechanisms, and various structural supports where weight, strength, and fatigue resistance are paramount.

- Consumer Goods and Electronics: Springs, clips, latches, and decorative elements are frequently produced via wire forming due to its efficiency and ability to handle high volumes with consistent quality.

The adaptability of Wire Forming ensures its continued relevance in meeting the evolving demands of these critical sectors, offering tailored solutions that optimize performance and cost.

Technical Advantages of Modern Wire Forming Solutions

Modern Wire Forming processes offer distinct technical advantages over other manufacturing methods, making them a preferred choice for countless applications requiring precision, durability, and cost-effectiveness.

- High Precision and Repeatability: Advanced CNC wire formers achieve extremely tight tolerances on dimensions and angles, ensuring consistent part quality across high-volume production runs. This is critical for assemblies where components must fit perfectly.

- Optimal Material Utilization: Wire forming is a near-net-shape process, meaning very little material is wasted as scrap, particularly compared to machining. This leads to significant material cost savings, especially with expensive alloys.

- Enhanced Material Strength: Cold forming processes, which are typical in wire forming, often work-harden the material, increasing its tensile strength and fatigue resistance without the need for additional heat treatment in some cases.

- Design Flexibility and Complexity: The ability to bend, coil, and manipulate wire in multiple axes allows for the creation of intricate 2D and 3D geometries that would be difficult or impossible to achieve with other methods.

- Cost-Efficiency for Volume Production: Once tooling and programming are established, the highly automated nature of wire forming results in very low per-unit costs for large production volumes, offering excellent ROI.

- Reduced Lead Times: Efficient setup and high-speed operation contribute to faster production cycles and quicker delivery of finished components.

These advantages collectively position modern Wire Forming as a superior choice for businesses seeking high-quality, reliable, and economical component manufacturing.

Choosing Your Partner: Vendor Comparison for Wire Forming Services

Selecting the right manufacturing partner for your Wire Forming needs is a critical decision that impacts product quality, cost, and delivery timelines. A thorough vendor comparison should consider several key factors beyond just price.

Key Comparison Criteria:

- Technical Expertise & Experience: Look for a vendor with proven experience in your specific industry and material requirements. Inquire about their engineering team's capabilities and problem-solving track record. CNTC Metal boasts over 20 years of expertise in metal fabrication, serving diverse industrial sectors.

- Quality Certifications: Verify adherence to international standards like ISO 9001, IATF 16949 (for automotive), AS9100 (for aerospace), or ISO 13485 (for medical). These certifications are indicative of robust quality management systems.

- Manufacturing Capabilities: Assess their equipment for wire diameter range, 2D/3D forming capabilities, secondary operations (welding, threading, finishing), and capacity for your required production volume.

- Customization & Prototyping: Can they support custom designs, rapid prototyping, and iterative development? A strong engineering design team is essential for complex projects.

- Lead Times & Logistics: Understand their typical lead times for prototypes and production runs, as well as their supply chain management and logistics capabilities.

- Customer Support & Warranty: Evaluate their responsiveness, post-sales support, and warranty policies.

Comparative Snapshot of Wire Forming Vendors (Illustrative)

| Feature | CNTC Metal | Vendor A (Competitor) | Vendor B (Specialist) |

|---|---|---|---|

| Years in Service | 20+ Years | 10 Years | 30+ Years (Niche) |

| Key Certifications | ISO 9001, IATF 16949, ISO 14001 | ISO 9001 | ISO 9001, AS9100 |

| Wire Diameter Range | 0.2mm - 16mm | 0.5mm - 8mm | 0.1mm - 5mm (Micro) |

| 3D Forming Capability | Excellent (Multi-axis CNC) | Moderate (2D focus) | Excellent (Complex microforms) |

| Typical Lead Time (Production) | 3-6 Weeks | 4-8 Weeks | 6-10 Weeks |

| Custom Solutions | Full Engineering Support | Limited Design Input | Specialized Design Input |

This comparison highlights how CNTC Metal positions itself as a comprehensive partner, offering broad capabilities, robust quality assurance, and dedicated engineering support, making us a reliable choice for diverse Wire Forming requirements.

Customized Solutions and Engineering Expertise

The complexity of modern industrial applications often necessitates components that are uniquely designed and precisely engineered. At CNTC Metal, our strength lies in providing fully customized Wire Forming solutions, leveraging our extensive engineering expertise from concept to final production.

- Collaborative Design & Prototyping: Our engineering team works closely with clients to understand specific application challenges, material requirements, and performance criteria. We utilize CAD/CAM software for design, simulation, and rapid prototyping, ensuring that the initial design meets all functional and structural specifications.

- Material Optimization: Based on the component's operating environment and load conditions, we advise on the optimal material selection, considering factors like corrosion resistance, temperature stability, and cost-effectiveness. This often involves specialized alloys for demanding environments.

- Tolerance & Performance Analysis: Through FEA (Finite Element Analysis) and other advanced modeling techniques, we analyze stress distribution, fatigue life, and deflection, ensuring the wire formed part will perform reliably under expected loads and conditions.

- Scalable Production: Whether it's a small batch of highly specialized components or millions of units for mass market applications, our production facilities are equipped to scale efficiently, maintaining consistent quality and meeting aggressive delivery schedules.

Our approach to customized Wire Forming is built on a foundation of technical excellence and a deep understanding of our clients' unique challenges, enabling us to deliver solutions that precisely fit their needs.

Real-World Application Case Studies

Demonstrating our capabilities in practice, these case studies illustrate how CNTC Metal's Wire Forming solutions have delivered tangible benefits to our clients.

Case Study 1: Automotive Engine Component Bracket

Challenge: A leading automotive manufacturer required a lightweight yet robust engine component bracket that could withstand high vibrations and temperature fluctuations, while also reducing overall vehicle weight for improved fuel efficiency. The previous cast component was heavy and involved significant post-machining.

Solution: Our engineering team collaborated with the client to redesign the bracket using advanced Wire Forming techniques from high-strength spring steel (SAE 9254). We optimized the geometry for maximum stiffness with minimal material, utilizing a multi-bend 3D wire form.

Results:

- Weight Reduction: Achieved a 35% weight reduction compared to the cast component.

- Cost Savings: Reduced per-unit manufacturing cost by 25% due to material efficiency and elimination of post-machining.

- Improved Performance: Enhanced vibration dampening properties and extended fatigue life confirmed through rigorous testing.

- Production Efficiency: Increased production rate by 40% using automated CNC wire formers.

Case Study 2: Medical Device Guide Wire

Challenge: A medical device company needed ultra-precise guide wires for minimally invasive surgical procedures. These wires required extremely tight tolerances, excellent biocompatibility, and specific flexibility/stiffness profiles.

Solution: We developed a specialized Wire Forming process for medical-grade stainless steel (316LVM) and Nitinol, focusing on micro-diameter wires. Custom tooling and advanced laser cutting were integrated for tip forming, ensuring a smooth, burr-free surface finish vital for patient safety.

Results:

- Precision: Achieved dimensional tolerances of ±0.01mm on critical features.

- Biocompatibility: Met ISO 10993 standards for biological evaluation of medical devices, confirmed by external lab testing.

- Functionality: Delivered consistent flexibility and torque response, crucial for surgical navigation.

- Regulatory Compliance: Full traceability and documentation provided, supporting FDA and CE submissions.

These cases exemplify our commitment to engineering excellence and our ability to deliver high-value Wire Forming solutions for the most demanding applications.

Frequently Asked Questions (FAQ)

Q: What is the minimum and maximum wire diameter you can work with?

A: Our advanced CNC Wire Forming machines can handle wire diameters ranging from 0.2mm (0.008 inches) up to 16.0mm (0.630 inches), accommodating a wide variety of industrial and commercial applications.

Q: What types of materials are commonly used in your wire forming process?

A: We work with a comprehensive range of materials, including various grades of stainless steel (e.g., 302, 304, 316, 17-7 PH), high carbon steel, spring steel, copper alloys, titanium, and specialty alloys like Inconel, chosen based on application requirements for strength, corrosion resistance, and temperature stability.

Q: Can you produce complex 3D wire forms?

A: Yes, our state-of-the-art multi-axis CNC wire bending machines are specifically designed to produce highly complex 2D and 3D geometries with exceptional precision and repeatability, including intricate bends, loops, and twists.

Q: What quality control measures do you have in place?

A: We adhere to strict ISO 9001 certified quality management systems. Our process includes in-line inspections, statistical process control (SPC), CMM (Coordinate Measuring Machine) dimensional verification, material testing, and final product inspections to ensure every component meets specified tolerances and performance criteria.

Q: Do you offer prototyping services for custom wire formed parts?

A: Absolutely. We provide comprehensive engineering support, including design assistance, material selection, and rapid prototyping services to help clients develop and validate custom wire formed solutions efficiently before moving to full-scale production.

Logistics and Support

Lead Time and Fulfillment

Our streamlined production processes and robust supply chain management enable efficient order fulfillment. Typical lead times for custom Wire Forming projects range from 3-6 weeks for initial production runs, depending on complexity, material availability, and order volume. Expedited services may be available upon request. We work closely with clients to establish realistic schedules and ensure on-time delivery.

Warranty Commitments

CNTC Metal stands by the quality and performance of our wire formed products. All components are manufactured to the highest industry standards and are covered by a limited warranty against defects in material and workmanship for a period of 12 months from the date of shipment. Specific warranty details are provided with each order, underscoring our commitment to client satisfaction and product reliability.

Customer Support Information

Our dedicated customer support team is available to assist you throughout the entire project lifecycle, from initial inquiry and design consultation to post-delivery support. For technical assistance, order status updates, or any inquiries, please contact us via:

- Email: info@cntcmetal.com

- Phone: +86-xxx-xxxx-xxxx (Example)

- Website: www.cntcmetal.com/contact.html

We are committed to providing prompt, professional, and effective support to ensure your complete satisfaction.

Conclusion

Modern Wire Forming is more than just bending metal; it is a precision engineering discipline that is crucial for a vast array of industrial applications. By combining advanced materials, sophisticated CNC technology, and rigorous quality control, CNTC Metal delivers wire formed components that meet the highest standards of performance, reliability, and cost-efficiency. Our dedication to innovation, customization, and comprehensive customer support positions us as an ideal partner for businesses seeking to leverage the full potential of wire forming technology. We invite you to explore our capabilities and discover how our expertise can drive the success of your next project.

References

- ASM International. (2000). ASM Handbook, Volume 14A: Metalworking: Forging and Extrusion. Materials Park, OH: ASM International.

- Kalpakjian, S., & Schmid, S. R. (2014). Manufacturing Engineering and Technology. Pearson Education.

- ISO. (2015). ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- American Society for Testing and Materials. (Current Edition). Various ASTM Standards for Metallic Materials. ASTM International.

- Society of Automotive Engineers. (Current Edition). IATF 16949: Quality management system requirements for automotive production and relevant service parts organizations. SAE International.

- Aerospace Quality System Standards. (Current Edition). AS9100: Quality Management Systems - Requirements for Aviation, Space and Defense Organizations. SAE International.

share:

-

Creative Ways to Decorate Your Tomato CageNewsAug.22,2025

-

Common Mistakes When Installing Brick Wall TiesNewsAug.22,2025

-

Customizing Conical Springs for Aerospace ApplicationsNewsAug.22,2025

-

Galvanized Tie Wire for Binding PipesNewsAug.22,2025

-

Environmental Impact of Using Snake Spacers in PlumbingNewsAug.22,2025

-

Sacrificial Formwork Systems for Complex StructuresNewsAug.22,2025

-

Wall Ties for Concrete: Invisible Guardians of Building Structural StabilityNewsAug.08,2025